The five key features that define non-slip shoes are a specific sole material, a specialized tread pattern, durable construction, water-resistant uppers, and official slip-resistant labeling. These elements work together in a system designed to maximize traction and maintain stability on hazardous wet or greasy surfaces.

The effectiveness of a non-slip shoe is not determined by a single feature, but by the engineered synergy between the sole's soft material, its liquid-channeling tread pattern, and its overall structural integrity.

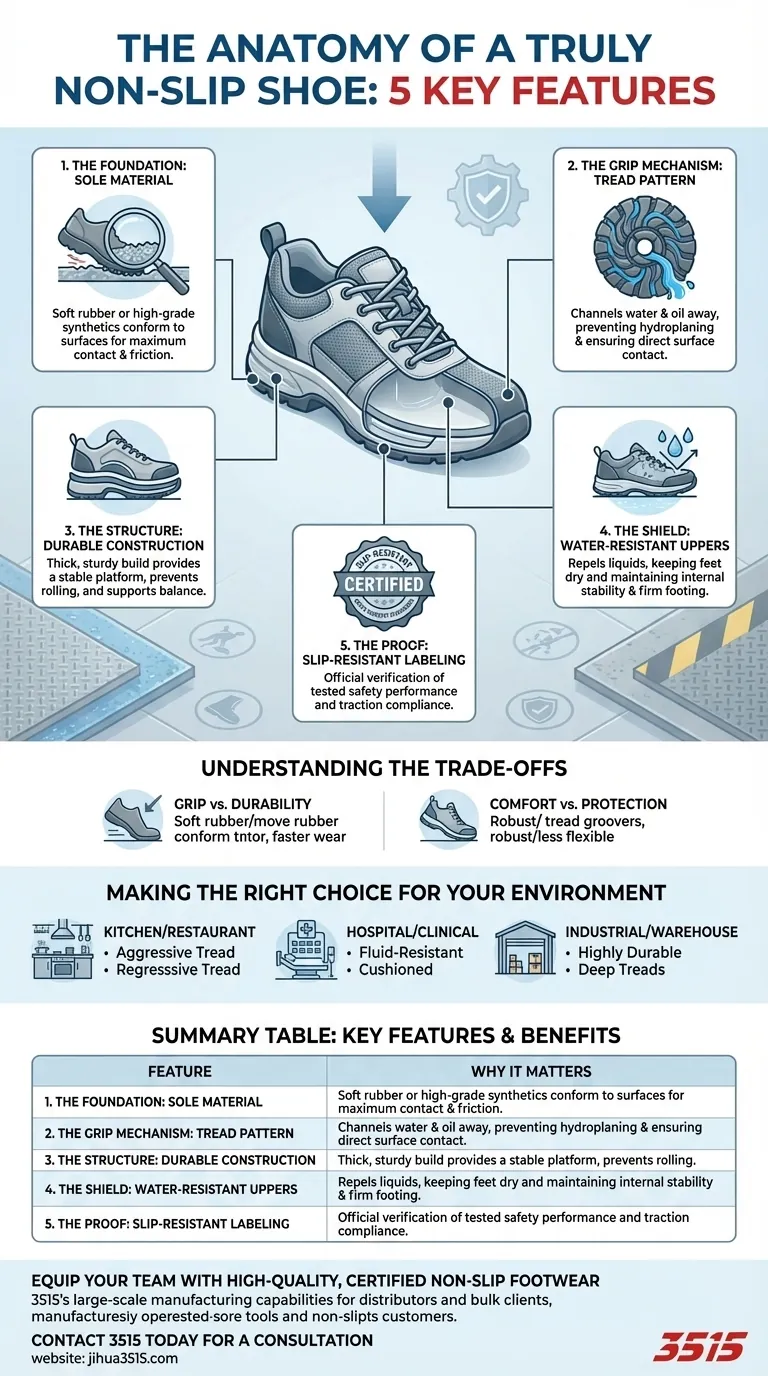

The Anatomy of a Truly Non-Slip Shoe

To understand what makes a shoe effective, you must look at how its individual components contribute to the primary goal: preventing falls. Each feature plays a distinct and critical role.

The Foundation: Sole Material

The most crucial element is the sole itself. Non-slip shoes overwhelmingly use soft rubber or high-grade synthetic materials.

Unlike hard, rigid plastics, this softer material can better conform to microscopic imperfections on a floor's surface, maximizing contact and friction.

The Grip Mechanism: Tread Pattern

The design of the sole's tread is just as important as the material. Effective non-slip shoes feature interlocking, circular, or grooved tread patterns.

Think of these patterns like the treads on a car tire. Their purpose is to channel water, oil, and other liquids out from under the shoe, allowing the sole to make direct contact with the solid floor. A flat-soled shoe would simply hydroplane.

The Structure: Durable Construction

A non-slip shoe must provide a stable platform for your foot. This requires thick, durable, and sturdy construction.

A well-built shoe prevents your foot from rolling or twisting during a near-slip, helping you maintain balance. Features like adequate arch support also contribute to stability and reduce fatigue over long shifts.

The Shield: Water-Resistant Uppers

While the sole provides the external grip, the upper part of the shoe protects your foot. Water-resistant materials are a key feature.

If water or other liquids soak into the shoe, your foot can slide around inside, compromising your stability. Keeping your feet dry is essential for maintaining a firm, consistent footing.

The Proof: Slip-Resistant Labeling

Finally, look for official verification. Legitimate non-slip footwear will have slip-resistant labeling or certification.

This label indicates the shoes have been tested and meet specific industry standards for traction. It’s the most reliable way to confirm you are buying a product designed and proven for safety.

Understanding the Trade-offs

Choosing the right shoe involves balancing competing factors. No single shoe is perfect for every environment.

Grip vs. Durability

The softest rubber compounds provide the best grip but often wear down more quickly, especially on abrasive surfaces like concrete or asphalt. You may need to replace them more frequently.

Comfort vs. Protection

Extremely durable construction with features like steel toes provides maximum protection but can add weight and reduce flexibility. For jobs requiring constant movement, you must balance robust protection with all-day comfort.

"Oil-Resistant" vs. "Slip-Resistant"

These terms are not interchangeable. "Oil-resistant" means the sole material won't degrade when exposed to oil, but it doesn't guarantee traction. Always look for the specific "slip-resistant" certification for safety.

Making the Right Choice for Your Environment

Your specific workplace hazards should guide your final decision.

- If your primary focus is a kitchen or restaurant floor: Prioritize an aggressive tread pattern specifically designed to channel away grease and water.

- If your primary focus is a hospital or clinical setting: Emphasize fluid-resistant uppers and cushioned, supportive construction for comfort during long hours on hard floors.

- If your primary focus is an industrial or warehouse environment: Look for highly durable construction and deep treads that can handle uneven or debris-covered surfaces.

Investing in footwear engineered for your specific risks is a critical component of professional safety.

Summary Table:

| Key Feature | Why It Matters |

|---|---|

| Sole Material | Soft rubber conforms to surfaces for maximum friction. |

| Tread Pattern | Channels liquids away to prevent hydroplaning. |

| Durable Construction | Provides a stable platform to maintain balance. |

| Water-Resistant Uppers | Keeps feet dry and stable inside the shoe. |

| Slip-Resistant Labeling | Official proof of tested safety performance. |

Ready to equip your team with high-quality, certified non-slip footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety shoes and boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of non-slip footwear, engineered with the precise features discussed here to protect your workforce.

We can help you source the right footwear for your industry's specific hazards, ensuring compliance, safety, and comfort.

Contact 3515 today for a consultation and let us provide the durable, reliable safety solutions your business needs.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Lightweight Breathable Training Shoes for Wholesale & Custom OEM Manufacturing

- Wholesale Leather Safety Boots with Customizable Protective Toe

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

People Also Ask

- Why does the material performance of professional slip-resistant shoes offer superior safety? Hardware vs. Behavior

- Why are metal surfaces often selected as the walking medium in studies concerning ramp safety? Achieve Lab-Grade Precision

- How do industrial safety shoes contribute to safety in sugar production? Ensure High-Altitude Inspection Security

- Why is compliance with safety standards such as PN EN ISO 20347:2012 critical? Ensure Certified Workplace Protection

- How do athletic-style safety shoes balance flexibility and safety? Perfect Agility for Active Professionals