It’s a scenario that keeps brand managers and distributors awake at night. You’ve just fulfilled a major contract for high-performance tactical boots, specified to be "durable and protective." Weeks later, the reports come in: the boots are a disaster. In the hot, arid environment they were deployed to, they're causing blisters and overheating. The client is furious, your reputation is on the line, and a massive, costly return is looming.

You thought you chose a quality product. So, what went wrong?

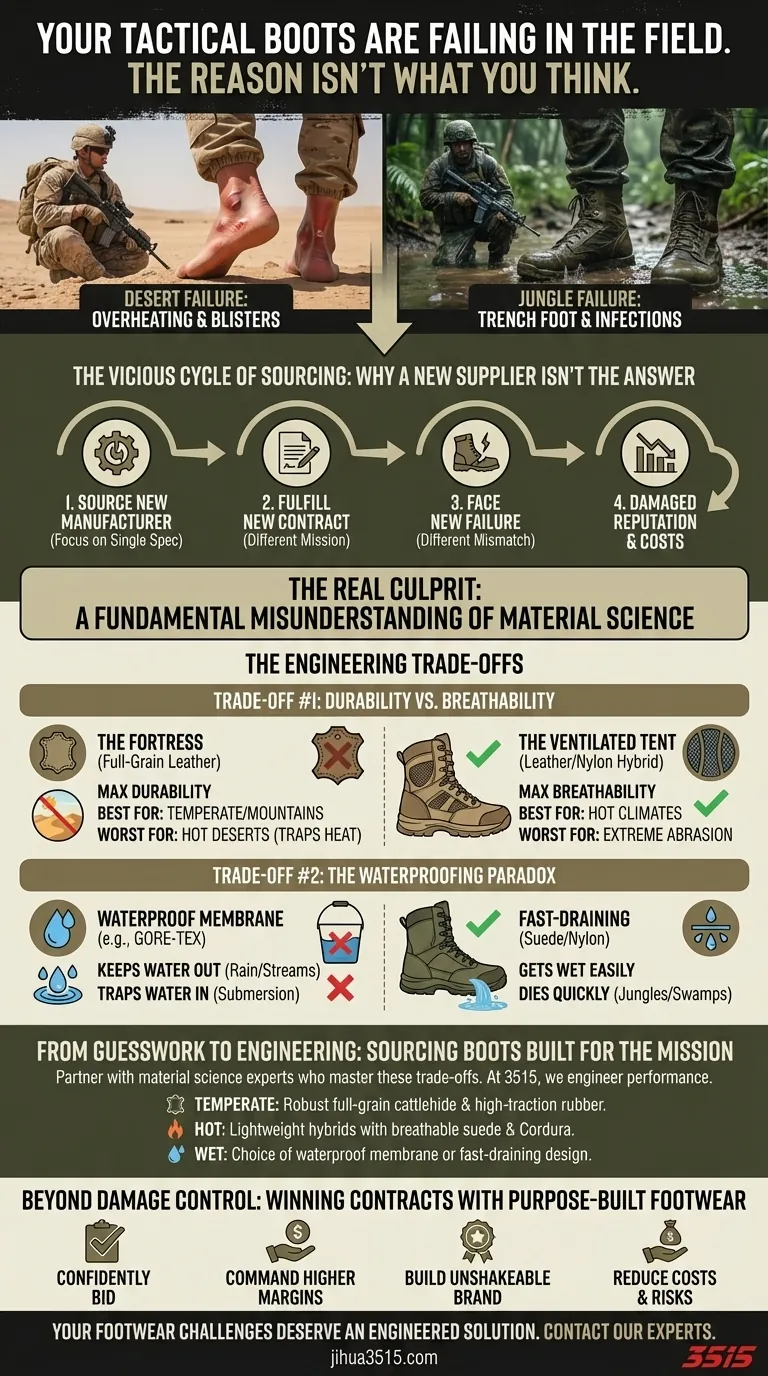

The Vicious Cycle of Sourcing: Why a New Supplier Isn't the Answer

When faced with a product failure of this magnitude, the typical reaction is to blame the supplier and search for a new one. This often leads to a frustrating and expensive cycle:

- Source a new manufacturer, focusing on a single specification that failed last time—perhaps you demand thicker leather or a more robust sole.

- Fulfill a new contract for a different client, this time for a mission in a wet, tropical climate.

- Face a new, different failure. The "indestructible" leather boots never dry out, leading to foot infections, and are too heavy for long patrols.

The result is the same: damaged client relationships, eroded profit margins from returns and warranty claims, and a brand that looks unreliable. The core problem isn't necessarily the quality of the manufacturing; it's that you're solving the wrong problem.

The Real Culprit: A Fundamental Misunderstanding of Material Science

The belief that a single "best" military boot exists is a myth. The truth is that every high-performance boot is a series of carefully balanced engineering trade-offs. Sourcing the right boot isn't about finding the "toughest" or "most waterproof" option; it's about matching the correct material science to a specific operational environment.

Failing to understand this is the root cause of repeated product failures. Let's break down the two most critical trade-offs.

Trade-Off #1: The Fortress vs. The Ventilated Tent (Durability vs. Breathability)

Think of a boot's upper as a form of shelter for the foot.

- A Fortress (Full-Grain Leather): A boot made mostly of thick, full-grain leather is incredibly durable and protective against rocks and abrasion. It’s a fortress. This is excellent for temperate climates and rugged mountains. But in a 110°F (43°C) desert, that fortress becomes an oven, trapping heat and moisture, leading directly to the blisters and overheating that caused your first contract to fail.

- A Ventilated Tent (Leather/Nylon Hybrid): A boot that strategically replaces leather panels with lightweight, breathable nylon (like Cordura) is a ventilated tent. It allows heat and sweat to escape, keeping the foot cooler and drier in hot climates. While it sacrifices some of the sheer abrasion resistance of the "fortress," it provides far superior performance in the heat.

Choosing the fortress for a desert mission is an engineering mismatch, and no amount of "quality" can fix it.

Trade-Off #2: The Waterproofing Paradox

Waterproof membranes like GORE-TEX sound like the ultimate solution, but they come with their own critical trade-off.

- Excellent for Crossing Streams: A waterproof boot is fantastic at keeping water out during temporary exposure, like walking through rain or crossing a shallow creek.

- A Disaster When Submerged: However, if that boot is fully submerged (e.g., wading through a swamp), water will eventually get in over the top. The waterproof membrane then works against the user, trapping that water inside. The boot becomes a bucket that can take days to dry, creating a perfect environment for trench foot and other infections.

In a consistently wet jungle environment, a non-waterproof but fast-draining boot made of suede and nylon is often the superior choice. It gets wet easily but also dries quickly. Demanding a "waterproof" boot for the wrong environment is another guaranteed path to failure.

From Guesswork to Engineering: Sourcing Boots Built for the Mission

To escape the cycle of failure, you need to shift from sourcing a commodity to delivering an engineered solution. This requires a manufacturing partner who doesn't just take orders, but deeply understands the science of materials and their application.

This is precisely where we excel. At 3515, we don't just manufacture footwear; we engineer performance.

Our approach is built on a mastery of these trade-offs. We work with you to define the exact operational environment your clients face—from the arid deserts of the Middle East to the humid jungles of Southeast Asia.

- For maximum durability in temperate climates, we construct boots with robust full-grain cattlehide uppers and high-traction rubber soles.

- For peak performance in hot environments, we engineer lightweight hybrids using breathable suede and Cordura panels.

- For wet conditions, we help you decide between a fully waterproof membrane for cold, wet weather or a fast-draining, quick-drying design for tropical climates.

By partnering with us, you are leveraging decades of manufacturing expertise to ensure the boots you provide are the right tool for the job, every single time.

Beyond Damage Control: Winning Contracts with Purpose-Built Footwear

When you stop guessing and start engineering, the entire dynamic of your business changes. Instead of constantly reacting to complaints and returns, you can proactively build a reputation for unmatched reliability.

Imagine being able to:

- Confidently bid on specialized contracts, knowing you can deliver footwear precisely tailored to any climate or terrain.

- Command higher margins because your products are trusted to perform when it matters most.

- Build an unshakeable brand that becomes the go-to standard for professional-grade tactical footwear.

- Drastically reduce the costs and risks associated with product returns and dissatisfied clients.

This is the strategic advantage that comes from having a true manufacturing partner. Your footwear challenges are unique, and they deserve an engineered solution, not a generic product. Let's discuss how our material science expertise and large-scale production capabilities can be tailored to your next project, ensuring success from the ground up. Contact Our Experts.

Visual Guide

Related Products

- Durable Leather Tactical Boots Wholesale & Custom Manufacturing for Brands

- Durable Leather High-Ankle Tactical Boots for Wholesale & Custom Manufacturing

- High-Traction Suede Tactical Boots Wholesale & Custom Manufacturing

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Durable High-Ankle Tactical Boots Wholesale Manufacturer for Custom & Bulk Orders

Related Articles

- Why Your ‘Best’ Tactical Boots Are Failing Your Team—And How to Fix Your Footwear Strategy

- Camouflage vs. Durability: The False Choice in Tactical Footwear

- Tactical vs. Combat Boots: How the Wrong Choice Is Costing Your Organization

- Beyond the Pattern: The Engineering That Separates True Tactical Boots from Costly Imitations

- Why Most Tactical Boots Fail: It’s Not the Durability, It’s the System