You launched a new line of tactical boots. They looked the part—rugged, aggressive tread, and a durable-looking build. But the market feedback is brutal. Customers complain they’re too heavy for long patrols, too stiff to run in, or the soles are separating after just a few months of hard use. Your brand's reputation is on the line, and a promising product category is becoming a costly liability. What went wrong?

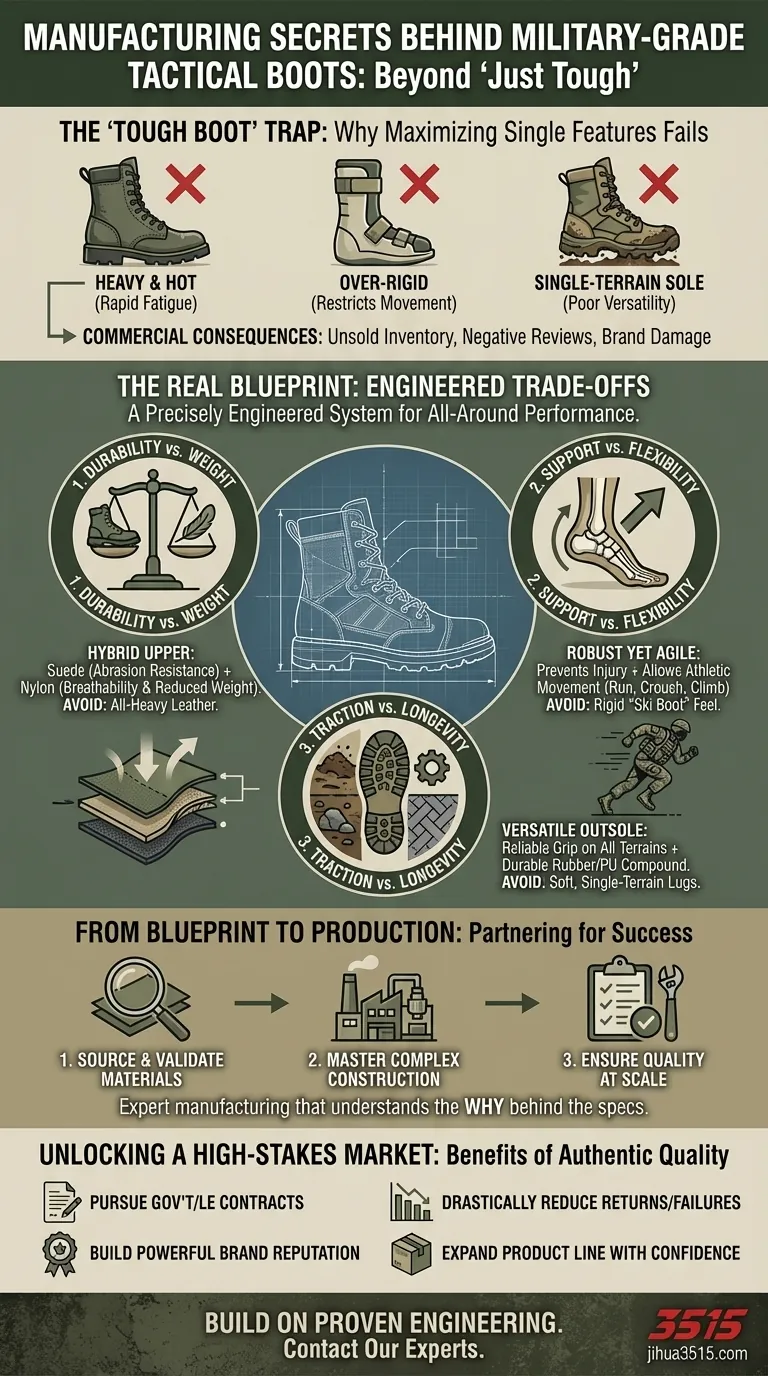

The "Tough Boot" Trap: When Durability Isn't Enough

For brand owners, distributors, and bulk purchasers entering the tactical footwear market, the mission seems simple: source the toughest boot possible. This often leads to a checklist approach focused on maximizing individual features: find the thickest leather, the most rigid ankle support, and the deepest tread.

This approach seems logical, but it’s the primary reason so many tactical footwear lines fail to gain traction. Here are the common missteps:

- Chasing Maximum Durability: Sourcing a boot made entirely of thick, heavy leather. The result is a product that’s incredibly heavy, causing rapid fatigue, and lacks the breathability needed for varied climates.

- Over-Engineering for Support: Creating a boot so rigid it feels more like a ski boot. While it might prevent ankle twists, it severely restricts natural movement, making it impossible for the wearer to run, crouch, or move athletically.

- Focusing on a Single-Terrain Sole: Choosing a sole with extremely deep, soft lugs designed for mud. This provides excellent grip in one specific environment but wears down quickly on pavement and offers poor traction on rocky surfaces.

The commercial consequences of these mistakes are severe. You're left with a warehouse full of inventory that doesn't sell, negative reviews that damage your brand's credibility, and a complete failure to penetrate the lucrative market of military, law enforcement, or serious civilian enthusiasts who know the difference.

The Real Blueprint: A Masterclass in Engineered Trade-Offs

The core issue isn't a lack of quality; it's a fundamental misunderstanding of the design philosophy. A genuine military combat boot isn’t the "toughest" boot in every single category. It is a precisely engineered system of compromises, optimized for all-around performance in unpredictable conditions.

This isn't just footwear; it's tactical equipment where every gram and every degree of flexibility is scrutinized. The "common solutions" fail because they try to maximize one attribute at the expense of the whole system. The real specifications reveal a different story.

The Trade-Off: Durability vs. Weight

The U.S. Army specifies a hybrid upper: suede leather on the lower sections and a strong fabric like nylon for the upper shaft. This isn’t a cost-cutting measure. It’s a deliberate engineering choice. The suede provides critical abrasion resistance where the foot meets rocks and debris, while the nylon drastically reduces weight and increases breathability, keeping the soldier effective and reducing fatigue over long distances. An all-leather boot is simply too heavy and hot for modern combat.

The Trade-Off: Support vs. Flexibility

An operator needs to be able to sprint from cover to cover, kneel, and climb. A boot that immobilizes the ankle is a liability. The military boot design provides robust support to prevent common injuries but is intentionally engineered to allow for a wide range of athletic movements. It hits the perfect balance point where protection doesn't hinder life-saving agility.

The Trade-Off: Traction vs. Longevity

The specified outsole, made from rubber or polyether polyurethane, is chosen for its versatility. It's designed to provide reliable traction across a vast range of terrains—from mud and sand to pavement and rock—without wearing out prematurely. It trades a small amount of peak performance in one specific area for high performance everywhere.

From Blueprint to Production: Finding a Partner Who Gets It

Understanding this philosophy of engineered trade-offs is one thing; executing it consistently across tens of thousands of units is another. To succeed in the tactical market, you need more than just a factory. You need a manufacturing partner who understands the why behind the specifications.

A true manufacturing expert must be able to:

- Source and Validate Materials: Consistently procure the specific suede, high-denier nylon, and polyurethane compounds that meet strict performance standards.

- Master Complex Construction: Possess the machinery and skilled labor to perfectly bond hybrid uppers and mold multi-terrain outsoles.

- Ensure Quality at Scale: Implement rigorous quality control to ensure every single boot delivers the same precise balance of support, flexibility, and durability.

This is where 3515 excels. We don't just assemble footwear; we engineer performance. Our deep experience in large-scale production is built on a foundational understanding of the principles behind military-grade equipment. We treat a tactical boot not as a shoe, but as a critical piece of gear, and we have the capabilities to produce it to the highest standards.

Beyond the Boot: Unlocking a High-Stakes Market

When you partner with a manufacturer that truly understands the intricate balance of tactical footwear design, the dynamic changes completely. You’re no longer just selling a "tough-looking" boot. You are providing a reliable, high-performance tool that your customers can depend on.

With this foundation, new possibilities open up:

- Confidently pursue government and law enforcement contracts.

- Build a powerful brand reputation among serious enthusiasts who recognize and value authentic quality.

- Drastically reduce returns and negative reviews associated with product failures.

- Expand your product line with the assurance of consistent, high-quality manufacturing.

Stop struggling with products that miss the mark. It's time to build your footwear line on a foundation of proven engineering and expert manufacturing. Our team is ready to help you translate the complex requirements of tactical footwear into a successful product for your brand or distribution network. Let's discuss the specific needs of your next project. Contact Our Experts.

Visual Guide

Related Products

- Durable Leather Tactical Boots Wholesale & Custom Manufacturing for Brands

- Durable Leather High-Ankle Tactical Boots for Wholesale & Custom Manufacturing

- Durable High-Ankle Tactical Boots Wholesale Manufacturer for Custom & Bulk Orders

- Wholesale Tactical Boots High-Traction & Reflective for Bulk & Brand Orders

- Wholesale Lightweight Tactical Boots with Dial Closure OEM & Bulk Orders

Related Articles

- Why Your ‘Best’ Tactical Boots Are Failing Your Team—And How to Fix Your Footwear Strategy

- Beyond the Pattern: The Engineering That Separates True Tactical Boots from Costly Imitations

- Why Even the Best Tactical Boots Fail—And How to Choose the Right Ones

- Why Your Team Hates Their New Tactical Boots: A Buyer's Guide to What Really Matters

- Camouflage vs. Durability: The False Choice in Tactical Footwear