Work boots are more than just protective footwear—they're engineered systems designed to mitigate specific workplace hazards. The outsole, as the only point of contact between the worker and the ground, plays a pivotal role in preventing slips, falls, and fatigue. This guide breaks down how outsole designs are optimized for different industrial environments, backed by material science and safety testing.

How Workplace Hazards Dictate Outsole Design

Every workplace presents unique underfoot challenges, and outsole engineering starts with hazard mapping. Research shows that 60% of workplace slips occur due to mismatched footwear and surface conditions—a preventable issue with proper outsole selection.

The Role of Tread Patterns in Traction Mechanics

Tread patterns aren't just about aesthetics; they're hydraulic systems for channeling liquids and debris:

- Multidirectional lugs (angled grooves) create edges that grip during lateral movements, critical for warehouse workers making quick turns.

- Siped soles (micro-grooves within tread blocks) flex to expose fresh gripping surfaces, like tire treads on wet roads.

- Deep lug designs (6–8 mm) prevent mud buildup on construction sites by shedding weight with each step.

Material Science: Rubber Compounds and Slip Resistance

The chemistry behind outsole materials determines performance in extreme conditions:

- Oil-resistant rubber incorporates nitrile blends that swell slightly upon contact with hydrocarbons, maintaining grip in automotive shops.

- Thermoplastic rubber (TPR) balances flexibility and durability for healthcare workers who need all-day comfort on polished floors.

- Gum rubber excels in cold storage facilities, remaining pliable at subzero temperatures where standard compounds harden.

Matching Boot Features to Industry-Specific Risks

Case Study: Oil-Resistant Outsoles in Automotive Workshops

Mechanics face a trifecta of hazards: oil, coolant, and polished concrete. Boots for this environment use:

- Closed-cell rubber that resists fluid absorption, preventing the "hydroplaning" effect.

- Wide contact patches distribute weight to reduce pressure points during prolonged standing.

- Non-marking compounds avoid leaving scuffs on customer vehicles—a detail often overlooked in safety specs.

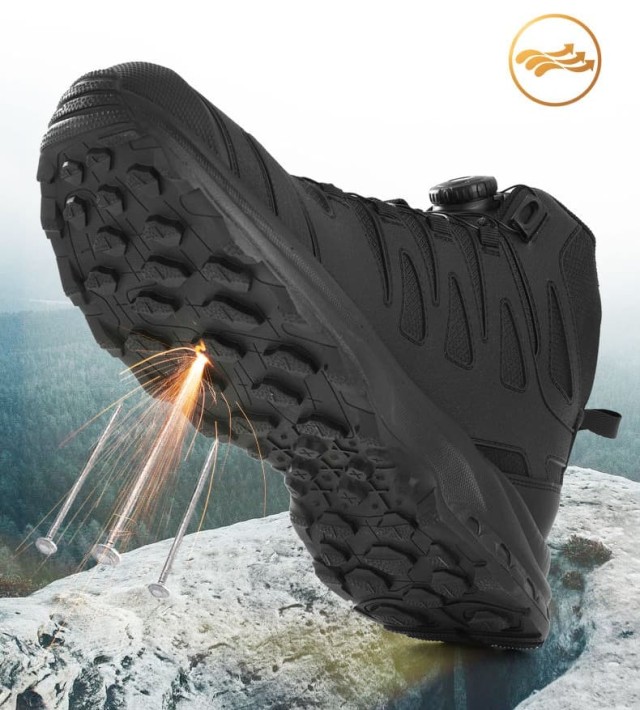

Construction Sites: Deep Lug Patterns for Uneven Terrain

A 2023 analysis of OSHA reports revealed that roofing and framing crews experience 3× more falls from uneven surfaces compared to other trades. Their boots require:

- Aggressive heel brakes (angled lugs at the heel) to arrest slides on steep pitches.

- Paddle-shaped lugs that clean themselves when flexed, maintaining traction in sticky clay soils.

- Rock plates (thin metal layers) embedded in the outsole to deflect nails and rebar.

Validating Safety: Certifications and Testing Standards

Not all "slip-resistant" claims are equal. Look for boots tested under:

- ASTM F2913 (wet incline testing): Measures the angle at which a boot begins to slide—industry leaders achieve 12°+ on greased steel.

- ISO 20347:2021 (occupational footwear): Requires energy absorption and puncture resistance for soles.

- EH-rated rubber (electrical hazard): Insulates against live circuits up to 18,000 volts in utility work.

Pro tip: Boots with SATRA TM144 certification undergo 5,000+ abrasion cycles, proving longevity in high-wear areas like mining tunnels.

Step Into Safer Workdays with 3515

At 3515, we engineer outsoles as precision tools—whether you're equipping oil rig crews needing chemical-resistant treads or hospital teams prioritizing silent, slip-proof strides. Our custom formulation service lets distributors and bulk buyers tailor compounds and tread depths to their clients' unique hazards.

Ready to upgrade your safety footwear line? Partner with 3515 to source boots where every outsole is a data-driven defense against workplace injuries.

How does your current footwear handle the "near-miss" moments your workers face daily?

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

Related Articles

- How Steel Toe Boots Deliver Financial and Safety Returns in High-Risk Workplaces

- How to Reduce Steel Toe Boot Risks Without Compromising Workplace Safety

- How Steel Toe Boots Meet Industry Safety Standards and Reduce Workplace Injuries

- How to Choose Steel Toe Shoes That Balance Safety and Comfort

- Matching Men’s Work Shoe Safety Technologies to Workplace Hazards