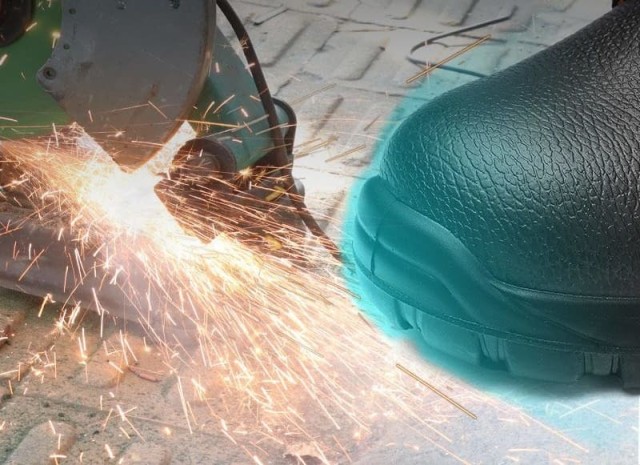

Steel toe boots are essential for workplace safety, but their weight, cold conductivity, and electrical risks can create new hazards. This guide reveals practical solutions—from smart material choices to industry-specific protocols—that maintain protection while addressing common pain points.

Understanding the Risks of Steel Toe Boots

How Weight and Design Impact Fatigue

Steel toe boots are typically 20-30% heavier than composite alternatives, increasing leg strain during long shifts. Research shows that every extra pound on your feet equates to carrying five pounds on your back—a key factor in chronic fatigue for warehouse and construction workers.

Mitigation Tip: Pair boots with shock-absorbing insoles and rotate between pairs to distribute wear patterns.

Cold Conductivity in Winter Work Environments

Metal toe caps act like heat sinks in freezing temperatures, dropping internal boot temperatures significantly. Workers in refrigeration or outdoor winter environments report discomfort within hours, which can lead to reduced focus on safety tasks.

Did You Know? Composite materials (carbon fiber, Kevlar) provide comparable protection without temperature transfer—ideal for cold storage facilities.

Electrical Hazards and Insulation Standards

Traditional steel toes conduct electricity, posing risks for electricians and utility workers. ASTM F2413-compliant boots use non-conductive materials (rubber, PVC) that withstand up to 18,000 volts without current leakage.

Critical Check: Always verify ASTM/ISO ratings for your industry—look for "EH" (Electrical Hazard) markings.

Proactive Solutions for Safer Use

Selecting the Right Fit: Beyond Shoe Size

Ill-fitting boots cause 60% of workplace foot injuries, from blisters to long-term joint damage. Proper sizing accounts for:

- Toe Box Space: 1-inch clearance beyond longest toe

- Arch Support: Prevents plantar fasciitis

- Ankle Mobility: Avoids restricted movement

Pro Tip: Try boots on with work socks and walk on inclined surfaces during fitting.

Material Innovations: Lightweight and Non-Conductive Alternatives

| Feature | Steel Toe | Composite Toe |

|---|---|---|

| Weight | Heavy | 30% lighter |

| Conductivity | High | None |

| Cost | $ | $$ |

Best For Electricians: Fiberglass-reinforced boots meet ASTM F2892-18 standards without metal components.

Industry-Specific Safety Protocols

- Construction: Prioritize boots with puncture-resistant soles (ASTM F2413-18) for rebar hazards.

- Warehousing: Cushioned midsoles reduce fatigue from concrete floors.

- Utilities: EH-rated boots with slip-resistant treads for wet conditions.

Long-Term Safety Practices

Maintenance Tips to Preserve Protective Features

- Daily: Remove debris from treads to maintain slip resistance.

- Weekly: Apply conditioner to leather to prevent cracks.

- Monthly: Inspect toe caps for dents compromising protection.

Warning Sign: Visible toe cap deformation means immediate replacement—damaged steel offers 40% less impact resistance.

When to Replace Steel Toe Boots: Wear and Tear Indicators

- Sole Separation: Gaps exceeding 1/4 inch

- Tread Depth: Below 1/8 inch (use a coin test)

- Liner Breakdown: Moisture buildup causes odor and blisters

Lifespan Benchmark: Most boots last 6-12 months with daily use—rotate pairs to extend durability.

Upgrade Your Safety Strategy with 3515 Footwear

As a trusted manufacturer for distributors and bulk buyers, 3515 combines OSHA-compliant designs with ergonomic innovations. Our non-conductive composite toe boots and climate-adaptive materials help you protect workers without sacrificing comfort. [Contact our team] to explore custom solutions tailored to your industry’s risks.

By addressing both protection and wearability, you’ll reduce injuries while improving worker compliance—a win-win for safety managers and frontline teams alike.

Products You Might Be Looking For:

Explore OSHA-compliant steel toe work boots

Related Products

- Wholesale Customizable Suede Safety Boots - Puncture-Proof with Velcro Closure

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

- Wholesale Durable Safety Boots | Custom Steel Toe & Puncture-Resistant Manufacturing

Related Articles

- How to Choose Work Boots That Balance Safety, Comfort, and Durability for Your Job

- Work Boots vs. Western Boots: How to Choose the Right Footwear for Labor Safety

- Steel Toe Work Boots: Balancing Safety and Comfort for Demanding Jobs

- How to Choose Work Boots That Match Your Job Demands and Safety Needs

- How to Choose Work Boot Materials for Maximum Safety and Durability