When evaluating workplace safety investments, few items offer as clear a return as steel toe boots. Beyond preventing injuries, these boots reduce compliance fines, lower replacement costs, and mitigate catastrophic financial risks. Here’s how the data validates their value.

How Workplace Injury Data Justifies Steel Toe Boot Costs

Conclusion: Steel toe boots reduce injury-related costs by over 70% in high-impact scenarios, while non-compliance penalties can exceed six figures annually.

The Hidden Costs of Foot Injuries

- Medical expenses for crushed toes or fractures often surpass $15,000 per incident, including surgery and rehabilitation.

- Lost productivity from recovery time averages 3–8 weeks per injury, compounding indirect costs.

- OSHA penalties for lacking proper foot protection range from warnings to fines exceeding $129,000 for repeat violations.

Prevention vs. Reaction

Research shows workplaces enforcing ASTM-compliant steel toe boots see:

- Fewer reported foot injuries (particularly in construction, manufacturing, and warehousing).

- Lower workers’ compensation claims—up to 60% reductions in some sectors.

Reflective Question: Could your current footwear policy withstand an OSHA audit while keeping workers safe?

Breaking Down the Long-Term Savings: Durability and Replacement Cycles

Conclusion: While steel toe boots cost 20–50% more upfront than standard work boots, their 2–3× longer lifespan offsets replacements.

Material Comparisons

| Feature | Steel Toe Boots | Composite Toe Boots |

|---|---|---|

| Lifespan | 18–24 months (heavy use) | 12–18 months |

| Impact Resistance | Higher (ASTM F2413-18 certified) | Moderate (lighter but less protective) |

| Best For | Construction, heavy industry | Electrical work, extreme temperatures |

Cost Over Time

- A $150 steel toe boot lasting 2 years costs $6.25/month, versus a $100 composite boot replaced yearly at $8.33/month.

- Fewer replacements also mean less downtime for workers procuring new footwear.

Human-Centered Insight: Durability isn’t just about savings—it’s fewer interruptions to workers’ routines.

Compliance Beyond Checklists: How Standards Reduce Liability Risks

Conclusion: ASTM F2413-18 compliance isn’t bureaucratic red tape; it’s a shield against lawsuits and insurance hikes.

Key Standards Explained

- Impact/Compression Resistance: Toe caps must withstand 75 ft-lbs of impact and 2,500 lbs of compression.

- Electrical Hazard (EH) Rating: Critical for electricians; steel toes lack this unless specially insulated.

- Puncture Resistance: Essential in environments with nails or sharp debris.

Liability Protection

- Employers using non-compliant footwear face negligence claims in injury lawsuits.

- Insurers often raise premiums after foot-injury incidents—sometimes by 10–30% annually.

Reflective Question: Does your current footwear meet the minimum standards, or does it actively mitigate risk?

Real-World Cases: When Steel Toes Prevented Catastrophic Costs

Conclusion: Documented incidents show steel toe boots preventing amputations, six-figure lawsuits, and even fatalities.

Case Highlights

- Construction Site: A 1,200-lb beam dropped onto a worker’s foot; the steel toe cap absorbed 90% of the force, limiting injuries to bruising.

- Manufacturing Plant: A misaligned press would have crushed toes without steel reinforcement, avoiding a $200,000 workers’ comp claim.

The Ripple Effect

- Morale: Workers in compliant boots report higher confidence in employer safety commitments.

- Reputation: Sites with fewer injuries attract better talent and client trust.

Human-Centered Insight: The true ROI isn’t just dollars saved—it’s legs saved, families kept whole, and businesses running smoothly.

Ready to Invest in Safety That Pays for Itself?

3515’s industrial footwear solutions blend compliance, durability, and cost efficiency—helping distributors and bulk buyers protect workforces while safeguarding budgets. Explore how our ASTM-certified designs can reduce your long-term risks.

Products You Might Be Looking For:

View high-performance steel toe work boots

Explore customizable safety work boots

Related Products

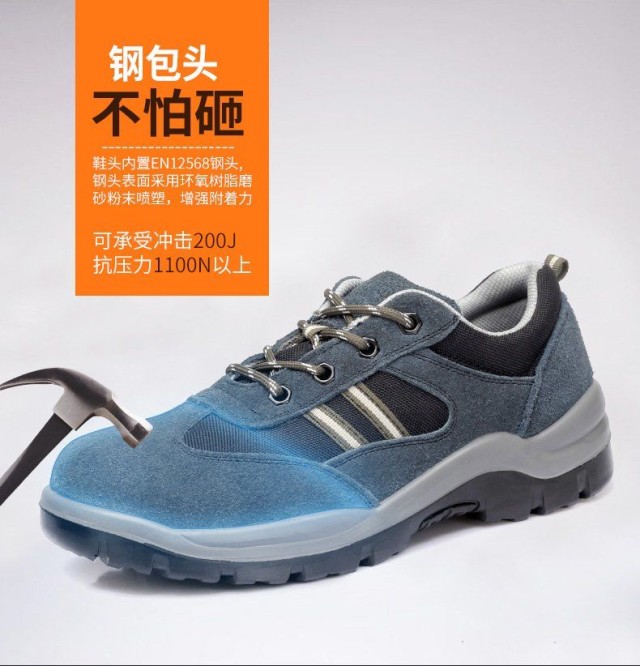

- Wholesale Customizable Suede Safety Boots - Puncture-Proof with Velcro Closure

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Wholesale Leather Safety Boots with Customizable Protective Toe

- Durable Leather Safety Boots for Wholesale & Custom OEM Manufacturing

Related Articles

- How Safety Work Boots Engineer Protection: Features and Standards for Targeted Hazard Mitigation

- Matching Men’s Work Shoe Safety Technologies to Workplace Hazards

- How to Choose Work Boots That Match Your Job Demands and Safety Needs

- How to Extend Work Boot Lifespan: Science-Backed Care for Safety & Savings

- How to Choose Work Boots That Match Your Job's Safety Demands