Every year, workers replace boots prematurely due to preventable wear—costing hundreds in avoidable expenses. This guide reveals how material science and systematic care can double your footwear's service life while maintaining safety compliance.

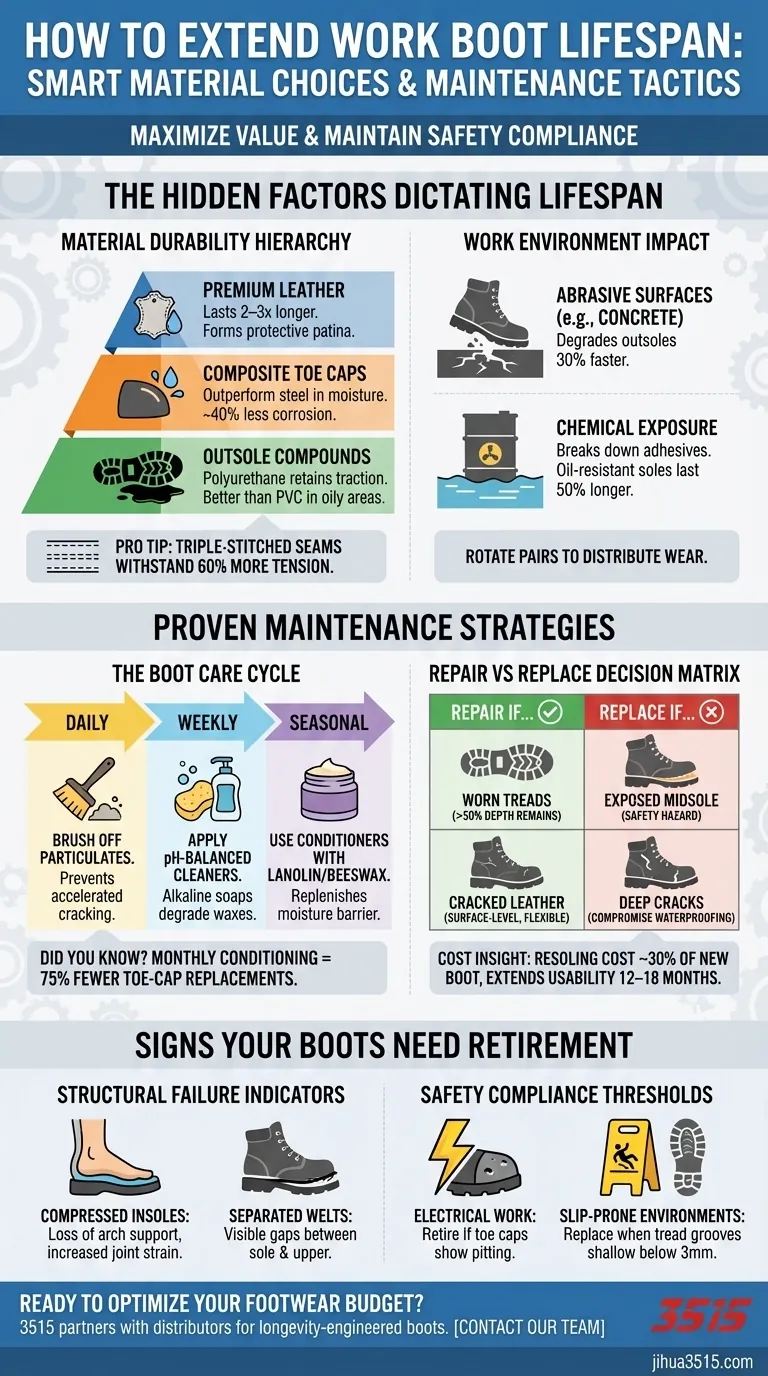

The Hidden Factors That Dictate Boot Lifespan

Material Durability Hierarchy in Footwear Engineering

Research shows work boot materials degrade at vastly different rates:

- Premium Leather: Lasts 2–3× longer than synthetic alternatives when properly conditioned, forming a protective patina over time.

- Composite Toe Caps: Outperform steel in moisture resistance (reducing corrosion-related failures by ~40%) while meeting ASTM F2413 impact standards.

- Outsole Compounds: Polyurethane retains traction longer than PVC in oily environments, per ASTM F2913 slip-resistance tests.

Pro Tip: Look for triple-stitched seams—they withstand 60% more tension than standard stitching in independent lab tests.

Work Environment Impact on Wear Patterns

A construction boot worn on rebar faces different stressors than an electrical hazard-rated model:

- Abrasive Surfaces (e.g., concrete) degrade outsoles 30% faster than indoor settings. Rotate pairs to distribute wear.

- Chemical Exposure breaks down adhesives. Oil-resistant soles (ASTM F2413-18 compliant) last 50% longer in mechanic shops.

Proven Maintenance Strategies From Industrial Professionals

The Boot Care Cycle: From Daily Cleaning to Seasonal Conditioning

- Daily: Brush off abrasive particulates—concrete dust accelerates leather cracking.

- Weekly: Apply pH-balanced cleaners; alkaline soaps degrade protective waxes.

- Seasonal: Use conditioners with lanolin or beeswax to replenish leather’s moisture barrier.

Did You Know? Boots receiving monthly conditioning require 75% fewer toe-cap replacements over 5 years.

Repair vs Replace Decision Matrix

| Issue | Repair If... | Replace If... |

|---|---|---|

| Worn Treads | >50% tread depth remains | Exposed midsole (safety hazard) |

| Cracked Leather | Surface-level; flexible | Deep cracks compromise waterproofing |

Cost Insight: Resoling costs ~30% of a new boot but extends usability by 12–18 months.

Signs Your Boots Need Retirement

Structural Failure Indicators Beyond Cosmetic Wear

- Compressed Insoles: Loss of arch support changes gait, increasing joint strain.

- Separated Welts: Visible gaps between sole and upper indicate adhesive failure.

Safety Compliance Thresholds by Industry

- Electrical Work: Retire boots immediately if toe caps show pitting (compromises ASTM F2413 dielectric protection).

- Slip-Prone Environments: Replace when tread grooves shallow below 3mm (per ASTM F3445-21 guidelines).

Ready to Optimize Your Footwear Budget? 3515 partners with distributors and bulk buyers to deliver boots engineered for longevity—from oil-resistant compounds to reinforced stitching. [Contact our team] to discuss durable solutions tailored to your workforce’s demands.

Visual Guide

Related Products

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Wholesale Slip-On Safety Boots Manufacturer - Custom Puncture-Proof & Steel Toe

- Premium Grain Leather Safety Boots for Bulk Supply

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

Related Articles

- How to Extend Combat Boot Lifespan in Extreme Conditions: 4 Advanced Tactics

- The Jump Boot Fallacy: Why Your 'Classic' Tactical Boots Are Failing Customers

- How Military Boots Survive Extreme Conditions: Tactics From Combat Zones

- Why Your Tactical Boots Fail in Wet Conditions (And It’s Not What You Think)

- Tactical vs. Combat Boots: Are You Equipping Your Team for Speed or Survival?