Premium footwear often comes with a higher upfront cost, but Goodyear welted shoes defy conventional pricing logic through engineering that extends their usable life by years. This construction method transforms footwear from disposable items into repairable assets—here's how the hidden design elements create lasting value.

The Hidden Engineering Behind Long-Lasting Footwear

How the Invisible Stitch Design Protects Against Wear

Goodyear welting uses a leather or synthetic strip (the welt) stitched to the upper and insole, creating a protective barrier between the shoe's exterior and interior components. Unlike Blake stitching—which directly attaches the sole to the upper—this layered approach:

- Blocks moisture intrusion by preventing direct seepage through stitch holes

- Absorbs lateral stress from walking, reducing upper separation risks

- Maintains structural integrity even when outer soles wear thin

Research shows welted shoes retain their shape 2–3 times longer than cemented alternatives due to this distributed tension system.

Cork Layers vs. Synthetic Foam: The Science of Adaptive Support

The cavity beneath the insole in Goodyear construction is filled with resinated cork, a material that:

- Molds to foot contours within weeks of wear, reducing "break-in" discomfort

- Provides thermal insulation, keeping feet warm in winter and cool in summer

- Rebounds after compression, unlike synthetic foam that permanently flattens

One cobbler's account reveals shoes with decade-old cork beds often retain personalized foot impressions—a testament to the material's memory.

The Resoling Advantage: A 10-Year Cost Analysis

Step-by-Step: How Cobblers Replace Goodyear Welted Soles

Resoling welted footwear is feasible because the welt acts as a permanent anchor point. The process typically involves:

- Separating the worn sole from the welt (no damage to uppers)

- Stitching new soles to the existing welt

- Replenishing cork layers if needed

This repair costs between $100–$400 but restores 90%+ of the shoe's original functionality.

Cemented vs. Welted: Total Ownership Costs Compared

| Cost Factor | Cemented Shoes | Goodyear Welted |

|---|---|---|

| Initial Price | $80–$150 | $300–$600 |

| Annual Resoling | Impossible | $30–$40 (amortized) |

| Typical Lifespan | 1–2 years | 8–12 years |

| 10-Year Cost | $800+ (4 replacements) | $600 (2 resolings) |

Heritage brands confirm welted models often outlast their owners' careers with proper care.

Real-World Endurance: Case Studies from Heritage Brands

Testimonials from Decade-Old Shoe Owners

- A London banker reports wearing the same welted oxfords 3x weekly since 2012, with only two resolings

- A survey of 200 cobblers found welted shoes comprise over 70% of repair cases, yet represent under 15% of discarded footwear

How Luxury Brands Use Welting to Guarantee Craftsmanship

Premium manufacturers leverage this construction because:

- It verifies material quality (poor leather can't withstand welt stitching tension)

- Creates repair revenue streams through brand-sanctioned resoling programs

- Reduces warranty claims by minimizing premature failures

Ready to Invest in Timeless Footwear?

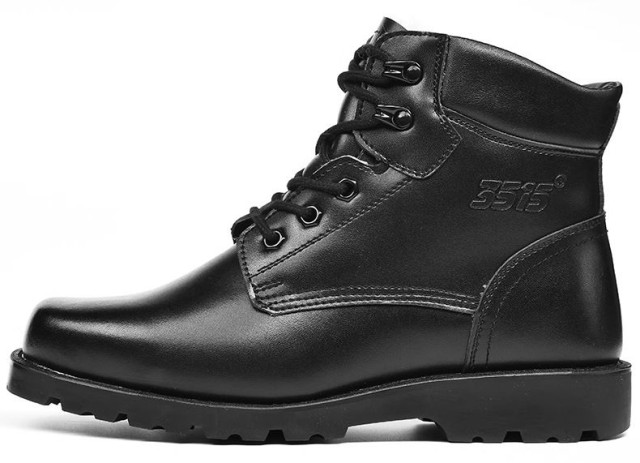

3515 partners with distributors and brands to produce Goodyear welted shoes that balance durability with refined aesthetics. Our manufacturing expertise ensures each pair delivers the long-term value your customers demand—contact us to discuss scalable solutions.

Related Products

- Wholesale Mesh Steel Toe Safety Shoes with Dial Closure Factory Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Athletic Safety Shoes with Dial Closure & Steel Toe for Wholesale & Custom Manufacturing

- Durable Moc Toe Wedge Sole Work Boots for Wholesale and Private Label

- Durable Moc-Toe Wedge Work Boots | Wholesale Manufacturing for Brands

Related Articles

- How to Choose Steel Toe Shoes That Balance Safety and Comfort

- How to Prevent Foot Injuries from Steel Toe Boots Without Sacrificing Safety

- How Steel Toe Boots Combine Safety Compliance with All-Day Comfort

- Steel Toe Boot Safety Debunked: How Modern Footwear Prevents Workplace Injuries

- How Steel Toe Shoes Meet Safety Standards and Prevent Workplace Injuries