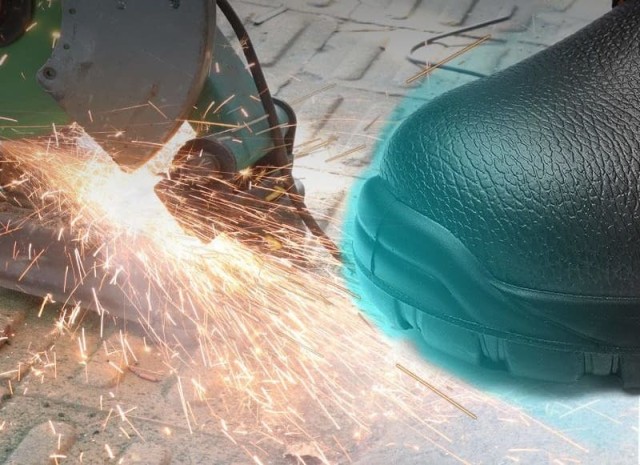

Steel toe boots are essential for workplace safety, but they can cause discomfort and injuries if not chosen or used correctly. This guide reveals practical strategies to maintain OSHA compliance while keeping your feet healthy—covering boot selection, ergonomic design features, and daily care techniques.

Understanding Steel Toe Boot Foot Injuries

How Steel Toe Caps Contribute to Discomfort

Steel toe caps protect against crushing injuries but can cause blisters, pressure points, and temperature-related discomfort. Their rigid structure limits natural foot movement, while their conductivity exposes feet to extreme heat or cold in certain environments.

Key considerations:

- Material conductivity: Steel conducts temperature and electricity, making it less ideal for electricians or workers in extreme climates.

- Weight: Heavier than composite alternatives, increasing fatigue during long shifts.

The Hidden Risks of Improper Sizing

Ill-fitting boots are a leading cause of foot injuries. Tight boots restrict circulation, while loose ones cause friction blisters. OSHA’s guidelines (ASTM 2413-18) mandate proper fit to ensure toe caps and metatarsal guards function as intended.

Warning signs of poor fit:

- Toes touching the cap when walking downhill

- Heel slippage exceeding half an inch

Selecting Boots for Safety and Comfort

Ergonomic Design Features to Look For

Prioritize boots with:

- Flexible toe caps: Composite materials (e.g., thermoplastic polyurethane) offer impact protection without rigidity.

- Metatarsal guards: Internal or external guards disperse energy from falling objects, reducing top-foot injuries.

- Arch support: Reduces strain during prolonged standing.

Pro Tip: For electrical or cold environments, composite toes are safer—they’re non-conductive and insulate against temperature extremes.

Importance of Material Flexibility and Breathability

Breathable linings (e.g., moisture-wicking mesh) prevent fungal infections, while shock-absorbing midsoles reduce joint stress. Look for ASTM-rated boots with:

- Puncture-resistant soles

- Slip-resistant treads

Proactive Care and Usage Strategies

Breaking-In Techniques to Avoid Blisters

- Gradual wear: Start with 1–2 hours daily, increasing over a week.

- Use thick socks: Cushion friction points during break-in.

- Condition leather boots: Softens material to mold to your foot shape.

Daily Maintenance for Long-Term Foot Health

- Rotate boots: Allow 24 hours between uses to dry sweat and reduce odor.

- Inspect soles: Replace worn treads to maintain slip resistance.

- Orthotic insoles: Add custom support if factory insoles lack cushioning.

Upgrade Your Safety Footwear with 3515

Whether you’re a distributor sourcing bulk orders or a brand owner seeking OEM solutions, 3515 delivers OSHA-compliant footwear engineered for comfort and durability. Explore our range of steel and composite toe boots designed to protect workers without compromising foot health.

Ready to equip your team with safer boots? [Contact 3515] for scalable manufacturing solutions tailored to your needs.

Related Products

- Wholesale Customizable Suede Safety Boots - Puncture-Proof with Velcro Closure

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

- Wholesale Leather Safety Boots with Customizable Protective Toe

Related Articles

- Steel Toe Work Boots: Balancing Safety and Comfort for Demanding Jobs

- How to Choose Work Boot Materials for Maximum Safety and Durability

- How Safety Work Boots Engineer Protection: Features and Standards for Targeted Hazard Mitigation

- How to Extend Work Boot Lifespan: Science-Backed Care for Safety & Savings

- Matching Men’s Work Shoe Safety Technologies to Workplace Hazards