Finding the right steel toe shoes isn’t just about meeting safety standards—it’s about ensuring all-day comfort without compromising protection. Whether you work in construction, manufacturing, or electrical maintenance, this guide breaks down key considerations to help you select footwear that fits your environment and workload.

Steel Toe Shoes: Protection Mechanisms and Use Cases

How Steel Toe Caps Prevent Workplace Injuries

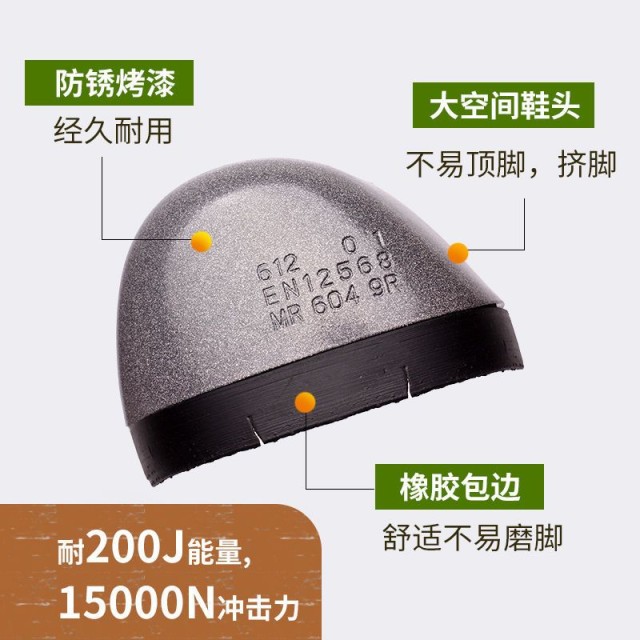

Steel toe shoes are engineered to protect against two primary hazards: impact (e.g., falling tools) and compression (e.g., heavy machinery rolling over feet). The reinforced toe box disperses force, reducing the risk of fractures or crush injuries.

Key features to look for:

- ASTM F2413 compliance: Ensures the shoe meets impact (75 ft-lbs) and compression (2,500 lbs) resistance standards.

- Metatarsal guards: Optional add-ons for industries with overhead hazards (e.g., logging).

Did you know? Research shows that steel toe shoes reduce foot injury severity by over 50% in high-risk environments.

Electrical Hazard Safety: Standards and Limitations

Not all steel toe shoes are suitable for electrical work. For environments with live circuits:

- ASTM F2413 EH-rated boots must withstand 18,000 volts for one minute without current leakage.

- Non-conductive materials: Outsoles and shanks should be rubber or composite to prevent conductivity.

Limitation: Steel toes alone don’t guarantee full electrical safety—pair them with dielectric insoles for added protection.

Weight vs. Durability: Debunking Myths About Steel Toes

Myth: "Steel toe shoes are unbearably heavy."

Reality: Modern designs use lightweight alloys and ergonomic soles, reducing weight by ~20% compared to traditional models.

Steel vs. Composite Toes:

| Feature | Steel Toe | Composite Toe |

|---|---|---|

| Weight | Heavier | Lighter (up to 30%) |

| Conductivity | Conducts electricity | Non-conductive |

| Best For | Construction, manufacturing | Electricians, cold climates |

Pro Tip: Composite toes won’t set off metal detectors—ideal for airport security or government facilities.

Choosing the Right Steel Toe Shoe

Industry-Specific Requirements

- Construction: Prioritize slip-resistant soles and puncture-proof midsoles for uneven terrain.

- Manufacturing: Look for oil-resistant outsoles and metatarsal guards near conveyor belts.

- Electrical Work: EH-rated boots with non-metallic shanks are mandatory.

OSHA Note: Employers must provide ASTM-compliant footwear if hazards are present, but workers can choose steel or composite options.

Innovations in Ergonomic Design for All-Day Wear

- Memory foam insoles: Reduce fatigue during 12-hour shifts.

- Ventilation channels: Prevent sweat buildup in humid environments.

- Flexible toe boxes: Allow natural foot movement without sacrificing protection.

Real-world impact: Workers in ergonomic steel toe shoes report 40% fewer complaints of foot pain.

Ready to Upgrade Your Safety Footwear?

3515 specializes in high-performance steel toe shoes tailored for distributors, brand owners, and bulk buyers. Our footwear combines industry-leading protection with all-day comfort—because safety shouldn’t come at the cost of mobility.

Explore 3515’s range today and equip your team with footwear that meets the toughest standards while keeping fatigue at bay.

Products You Might Be Looking For:

Explore athletic-style steel toe work shoes

View high-performance leather steel toe boots

Related Products

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Mesh Steel Toe Safety Shoes with Dial Closure Factory Production

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

Related Articles

- Steel Toe Work Boots: Balancing Safety and Comfort for Demanding Jobs

- Matching Men’s Work Shoe Safety Technologies to Workplace Hazards

- Steel-Toe vs. Composite-Toe Boots: How to Choose the Right Safety Footwear for Your Job

- How to Reduce Foot Injury Risks in High-Risk Workplaces: 3 Proven Strategies

- How Steel Toe Shoes Prevent Injuries: The Science Behind Workplace Safety