Replacing the factory insoles in your walking or hiking shoes is a strategic move to upgrade internal stability and customize fit. While the exterior of a shoe is built for durability, stock insoles are often generic placeholders that lack specialized arch support. Swapping them out allows you to correct fit volume, restore lost cushioning, and prevent fatigue as the materials degrade over their 300 to 500-mile lifespan.

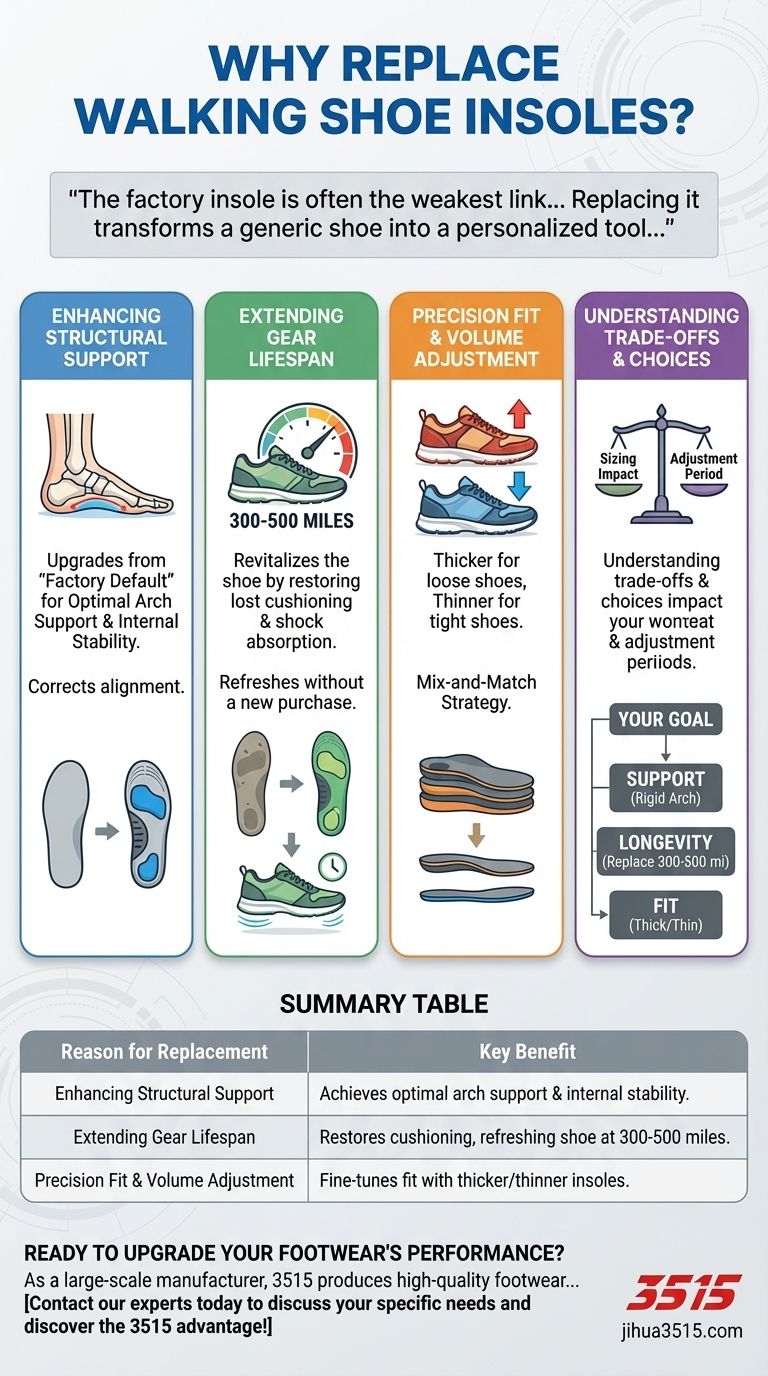

The factory insole is often the weakest link in high-performance footwear. Replacing it transforms a generic shoe into a personalized tool, extending the shoe's usable life while aligning the foot for optimal movement.

Enhancing Structural Support

Upgrading from "Factory Default"

Most shoes come with basic insoles designed to fit an average foot shape. By switching to aftermarket options, you can achieve optimal arch support tailored to your specific foot mechanics.

Improving Internal Stability

Stock insoles are often flimsy and flat. A structured replacement improves internal stability, ensuring your foot remains aligned within the shoe rather than sliding or collapsing inward during a walk or hike.

Extending Gear Lifespan

The Mileage Mismatch

A quality walking shoe or hiking boot often outlasts its original cushioning. While the outsole may be rugged, insoles typically reach the end of their lifespan between 300 to 500 miles.

Revitalizing the Shoe

Many hikers replace insoles long before the shoe itself is ready for retirement. Replacing a compressed insole restores comfort and shock absorption, essentially "refreshing" the shoe without the cost of buying a new pair.

Precision Fit and Volume Adjustment

Controlling Internal Volume

Insoles are a tool for fine-tuning how a shoe fits. You can utilize thicker insoles to reduce empty space in a shoe that feels too loose, or thinner insoles to create more room in a shoe that feels tight.

The Mix-and-Match Strategy

You are not limited to buying new products immediately. It is a viable strategy to mix and match insoles from your current rotation of shoes to find the combination of thickness and support that solves your specific fit issue.

Understanding the Trade-offs

Impact on Shoe Sizing

Adding a more supportive, structured insole often consumes more space inside the shoe than the factory liner. This can inadvertently make a well-fitting shoe feel too tight or restrict toe movement.

The Adjustment Period

Unlike soft factory foam, corrective insoles change the geometry of your stride. This requires a break-in period where your arches may feel sore or fatigued as they adapt to the new internal stability.

Making the Right Choice for Your Goal

To maximize the utility of your walking shoes, choose your replacement strategy based on your specific constraint:

- If your primary focus is Support: Prioritize aftermarket insoles that offer rigid arch structures to correct alignment and stability issues.

- If your primary focus is Longevity: Replace your insoles every 300 to 500 miles to maintain cushioning, even if the shoe's exterior looks fine.

- If your primary focus is Fit: Use thicker insoles to tighten a loose shoe, or thinner low-profile insoles to relieve pressure in a tight shoe.

Your shoes are the foundation of your movement; the insole is the interface that makes that foundation work for you.

Summary Table:

| Reason for Replacement | Key Benefit |

|---|---|

| Enhancing Structural Support | Achieves optimal arch support and internal stability for your foot mechanics. |

| Extending Gear Lifespan | Restores cushioning and shock absorption, refreshing the shoe at 300-500 miles. |

| Precision Fit & Volume Adjustment | Fine-tunes shoe fit by using thicker or thinner insoles to control internal space. |

Ready to upgrade your footwear's performance?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-quality footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, ensuring durability and comfort built to last.

Let us help you find or create the perfect foundation for your movement. Contact our experts today to discuss your specific needs and discover the 3515 advantage!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium KPU Athletic Safety Shoes for Wholesale

- Wholesale Durable & Breathable Training Shoes for Custom Brands

- Wholesale Modern Comfort Shoes with Dial Closure for Private Label & Bulk Orders

- Wholesale Breathable Athletic Sneakers - Custom Lightweight Cushioned Footwear Manufacturer

People Also Ask

- What types of walking braces are available? Choose the Right Support for Your Injury

- What are traction cleats, and when are they used? Master Winter Walking Safety

- What materials are used in exotic cowboy boots? A Guide to Luxury Hides and Their Unique Appeal

- How can one balance snake protection with comfort during long hikes? Master the Layered Safety System

- What are the main categories of modern walking boots? Choose the Right Boot for Your Adventure

- When can a patient transition to weight bearing with the walking boot? A Guide to Safe Recovery

- What are some tips for finding the right walking shoe fit? Walk Comfortably and Prevent Injury

- Can water-resistant boots dry quickly if they get wet? The Science of Breathable Footwear