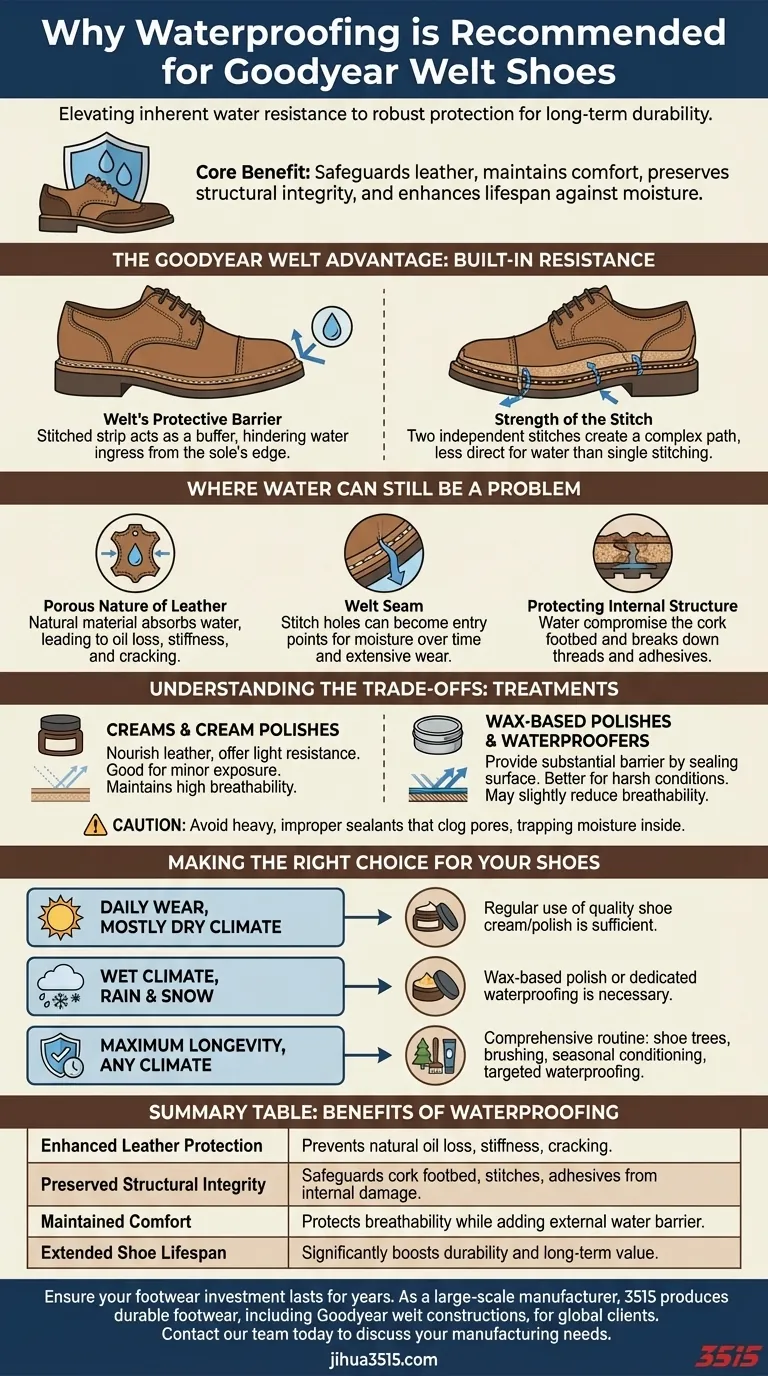

At its core, waterproofing is recommended for Goodyear welt shoes to elevate their inherent water resistance into more robust protection. This preventative care safeguards the leather, maintains comfort, and preserves the shoe's structural integrity, significantly enhancing its durability against moisture.

The Goodyear welt construction provides excellent water resistance, but not complete waterproofing. Applying a treatment closes this gap, protecting your investment from the long-term damage that repeated water exposure can cause.

The Built-in Advantage: Why Goodyear Welts Resist Water

A Goodyear welted shoe is engineered for durability, and that design provides a natural defense against water from the ground up.

The Welt's Protective Barrier

The "welt" is a strip of leather stitched around the bottom edge of the shoe's upper. This component acts as a buffer between the upper and the outsole.

This design means water has a much harder time seeping in from the side of the sole, which is a common failure point in lesser constructions.

The Strength of the Stitch

The Goodyear welt method uses two independent stitches. One attaches the welt to the upper and insole, and another attaches it to the outsole.

This creates a more complex and less direct path for water to travel into the shoe's interior compared to a single stitch that goes straight through to the inside.

Where Water Can Still Be a Problem

While highly resistant, the construction is not a perfect seal. The materials themselves are the primary reason additional waterproofing is a wise decision.

The Porous Nature of Leather

Leather is a natural, porous material. Both the upper and a traditional leather sole will absorb water if exposed for long enough.

When leather becomes saturated and then dries, it can lose its natural oils, leading to stiffness, cracking, and a shortened lifespan.

The Welt Seam

Over time and with extensive wear, the stitch holes along the welt can become potential points for moisture to wick through, especially during prolonged exposure like walking through puddles or snow.

Protecting Internal Structure

Water that gets inside can compromise the cork footbed, which is essential for comfort and support. It can also lead to premature breakdown of the threads and adhesives used in construction.

Understanding the Trade-offs

Applying waterproofing treatments is a balancing act. It's crucial to use the right products to avoid potential downsides.

Breathability is Key

One of leather's greatest assets is its breathability. Heavy, improper sealants (like some silicone sprays) can clog the leather's pores entirely.

This traps moisture and perspiration inside the shoe, which can lead to discomfort and accelerate the breakdown of the leather from the inside out.

Creams vs. Waxes

Conditioning creams and cream polishes nourish the leather and offer a light level of water resistance, which is often sufficient for minor exposure.

Wax-based polishes and dedicated waterproofing products provide a much more substantial barrier by sealing the surface. These are better for harsher conditions but may slightly reduce breathability.

Making the Right Choice for Your Shoes

Your approach to waterproofing should match your environment and how you use your shoes.

- If your primary focus is daily wear in a mostly dry climate: Regular use of a quality shoe cream or cream polish will provide enough protection for occasional encounters with rain.

- If you live in a wet climate or frequently face rain and snow: Applying a wax-based polish or a dedicated waterproofing conditioner is a necessary step to protect your investment.

- If your goal is maximum longevity regardless of climate: A comprehensive care routine including shoe trees, regular brushing, and seasonal conditioning with targeted waterproofing is the best strategy.

Proactive care ensures your Goodyear welted shoes will not only survive the elements but thrive for years to come.

Summary Table:

| Benefit of Waterproofing | Why It Matters |

|---|---|

| Enhanced Leather Protection | Prevents loss of natural oils, stiffness, and cracking from water exposure. |

| Preserved Structural Integrity | Safeguards the cork footbed, stitches, and adhesives from internal moisture damage. |

| Maintained Comfort | Protects breathability while adding a barrier against external water. |

| Extended Shoe Lifespan | A preventative measure that significantly boosts durability and value. |

Ensure your footwear investment lasts for years. As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including those built with robust constructions like the Goodyear welt. Let us help you provide high-quality, long-lasting footwear to your customers. Contact our team today to discuss your manufacturing needs.

Visual Guide

Related Products

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Custom OEM Training Shoes Wholesale Manufacturer Durable & Breathable

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

People Also Ask

- Which type of sole is better for hard surfaces? Rubber Soles for Superior Comfort & Durability

- What are the advantages of rubber-soled shoes? Unlock Superior Grip & All-Day Comfort

- What causes white marks on rubber boots, and how can they be removed? A Guide to 'Blooming' & Boot Care

- What factors determine the slip resistance of rubber-soled shoes? Tread, Compound & Design Explained

- What material is commonly used for the soles of non-slip footwear and why? Unlock the Secrets of Safe Footwear