Okay, so the task at hand is to craft a guide for fellow professionals like myself, explaining why ASTM F2413 is crucial. I need to make it clear, not just what it is, but why it actually matters for real-world safety.

First, I need to get inside the heads of my audience. They're smart, they're busy, and they need practical information, not jargon. So, I'll start with the hook. I'll make it bold and clear: At its core, understanding ASTM F2413 is about ensuring safety, not just checking a box. I will explain it ensures footwear provides the necessary protection against specific workplace hazards.

I'll put the big idea front and center.

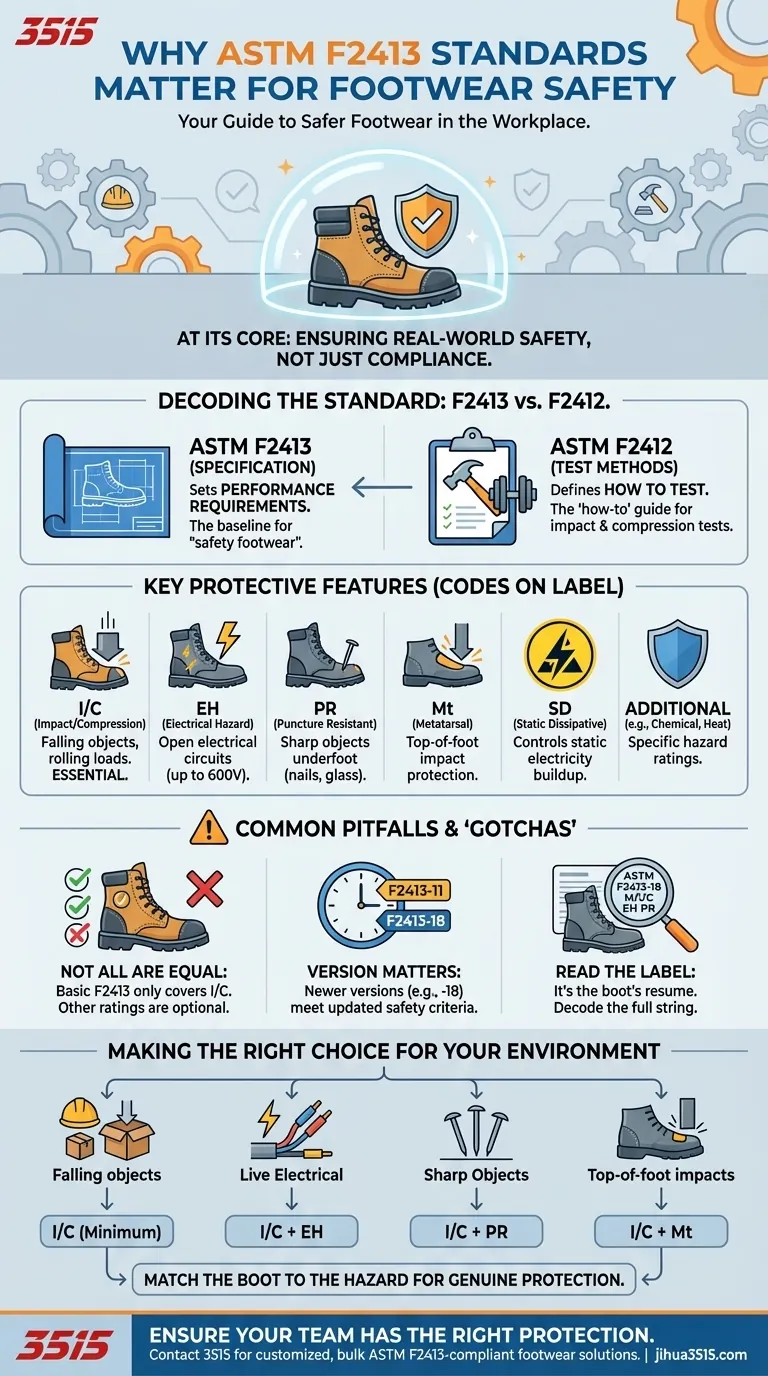

Key Takeaway: ASTM F2413 is the language of safety for footwear. It defines what "safety footwear" actually means. Understanding the standard empowers you to choose the right boots for your specific needs, protecting yourself and your team from real-world hazards.

Now, let's break it down.

Decoding the Standard: More Than Just a Steel Toe

Okay, I'll explain what ASTM F2413 is all about.

The Role of ASTM F2413

I'll make it clear that ASTM F2413 is the specification that dictates performance requirements. It sets the baseline for a boot to be labeled "safety footwear."

The Companion Standard: ASTM F2412

And here's where things get tricky. I need to clarify the relationship between F2413 and its cousin, F2412. F2412 is all about test methods – how do you test if a boot can handle an impact or compression? F2413 then sets the requirements that a boot must pass based on those test methods. It's a critical difference.

Key Protective Features Covered

I'll then dive into the actual features and benefits. I'll use examples from the references (Metatarsal, Electrical Hazard) and expand on them (like Puncture Resistance (PR), Static Dissipative (SD)) to show my expertise. I need to spell it out. Safety boots can include the following protections:

- I (Impact)

- C (Compression)

- EH (Electrical Hazard)

- Mt (Metatarsal)

- PR (Puncture Resistant)

- SD (Static Dissipative)

This is the good stuff – the actionable advice. It addresses the "Deep Need" of knowing what to look for.

Understanding the Trade-offs and Common Pitfalls

Now, the "gotchas." I need to anticipate the questions.

Not All "Safety Boots" Are Created Equal

First, I need to drive home the point that the basic F2413 label only ensures Impact (I) and Compression (C) resistance. It's not a magic bullet. Other ratings (EH, PR, Mt) are optional. A boot can be F2413 compliant without having puncture resistance, and that's critical to understand.

The Importance of the Version Number

I'll bring up the version numbers (F2413-11 vs. F2413-18). It's a great example of an evolving standard. The newer version means updated safety criteria, and boots from each version are tested against different criteria.

Reading the Label is Non-Negotiable

Finally, I need to stress how vital it is to decode the label itself. It's like the boot's resume. The codes (e.g., ASTM F2413-18 M/I/C Mt EH) summarize the protections. I'll show readers how to understand them because that's practical, empowering knowledge.

Making the Right Choice for Your Environment

I'll wrap it up with a section on how to match the boot to the hazard, with bullets, so it's super actionable. I'll state that the best boot is determined by the specific hazards of the job site. This is crucial for reader success:

- If your primary focus is protection from falling objects: Ensure the boot is rated for Impact (I) and Compression (C) at a minimum.

- If your primary focus is working around live electrical circuits: You must select a boot with an Electrical Hazard (EH) rating.

- If your primary focus is preventing nail or sharp object punctures: The boot must have a Puncture Resistant (PR) designation on its label.

- **If you need the highest level of top-of-foot In short, understanding ASTM F2413 is crucial because it is the primary standard that guarantees a safety boot meets specific, testable performance requirements for protection. This standard acts as a universal language for workplace safety, allowing you to accurately match your footwear to the real-world hazards you face, ensuring not just compliance, but genuine protection against injury.

The core issue is that not all safety footwear is created equal. Understanding the ASTM F2413 standard moves you from simply buying a "safety boot" to strategically selecting a piece of personal protective equipment certified to defend against the specific risks of your job.

Decoding the Standard: More Than Just a Steel Toe

To make an informed decision, you must understand what the ASTM F2413 specification truly represents. It's a detailed blueprint for safety, not a single feature.

The Role of ASTM F2413

ASTM F2413 is the Standard Specification for Performance Requirements for Protective (Safety) Toe Cap Footwear. This specification sets the minimum requirements for design, performance, testing, and classification.

If a boot is labeled "ASTM F2413," it means it has been certified to meet the foundational criteria for impact and compression resistance for the toe area.

The Companion Standard: ASTM F2412

You will often see ASTM F2412 mentioned alongside F2413. Think of F2412 as the "how-to" guide for testing.

ASTM F2412 defines the Standard Test Methods for Foot Protection. It outlines exactly how to perform tests for things like impact and compression. A boot must pass the tests defined in F2412 to meet the requirements of the F2413 specification.

Key Protective Features Covered

While impact and compression resistance are the baseline, the F2413 standard covers numerous other specific hazards. These are designated by codes on the boot’s certification label.

Key ratings include Metatarsal Protection (Mt) for top-of-foot injuries, Electrical Hazard (EH) for protection against open circuits, and Puncture Resistance (PR) for shielding against sharp objects underfoot.

Common Pitfalls to Avoid

Simply knowing the standard exists is not enough. Misinterpreting the details can lead to a false sense of security.

Not All Compliant Boots Are the Same

A boot can be ASTM F2413 compliant by only meeting the minimum requirements for toe impact (I) and compression (C).

It does not automatically include protection for other hazards like punctures or electrical shock. You must check the boot's specific label to see which additional protective features it is rated for.

The Importance of the Version Number

The standard is periodically updated to reflect new research and technology. You will see this noted with a year, such as ASTM F2413-11 or ASTM F2413-18.

A newer version number indicates the footwear was tested against more current safety criteria. For maximum assurance, always opt for boots certified under the latest version of the standard.

Reading the Label is Non-Negotiable

The information you need is printed on a label inside the boot, typically on the tongue. A line of codes like ASTM F2413-18 M/I/C EH PR tells you everything.

This example means the boot meets the 2018 standard, is for a Male (M), and is rated for Impact (I), Compression (C), Electrical Hazard (EH), and Puncture Resistance (PR).

Making the Right Choice for Your Environment

Your selection should be dictated entirely by a clear-eyed assessment of your workplace hazards. Use the standard's language to find the precise tool for the job.

- If your primary focus is protection from falling objects: Ensure the boot is rated for Impact (I) and Compression (C) at a minimum.

- If your primary focus is working around live electrical circuits: You must select a boot with an explicit Electrical Hazard (EH) rating.

- If your primary focus is preventing nail or sharp object punctures: The boot must carry the Puncture Resistant (PR) designation on its label.

- If your primary focus is guarding against top-of-foot impacts: Look for the Metatarsal (Mt) rating in addition to the standard I/C requirements.

By learning to read and apply this standard, you become an active and informed agent in your own safety.

Summary Table:

| Key ASTM F2413 Ratings | What It Protects Against | Essential For |

|---|---|---|

| I/C (Impact/Compression) | Falling objects, rolling loads | All industrial workplaces |

| EH (Electrical Hazard) | Open electrical circuits up to 600V | Electrical, utility, and manufacturing jobs |

| PR (Puncture Resistant) | Sharp objects like nails or glass | Construction, demolition, waste management |

| Mt (Metatarsal) | Top-of-foot impacts | Heavy manufacturing, logging, material handling |

| SD (Static Dissipative) | Static electricity buildup | Electronics manufacturing, explosive environments |

Ensure Your Team Has the Right Protection

As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM F2413-compliant footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, ensuring your workforce has the precise protection they need.

We provide:

- Customized Solutions: Tailored safety footwear matching your specific hazard requirements.

- Bulk Order Expertise: Reliable, high-volume production to meet your supply chain demands.

- Quality Assurance: Every pair meets or exceeds ASTM F2413 standards for guaranteed protection.

Protect your most valuable asset—your people. Contact 3515 today to discuss your safety footwear needs and receive a customized quote.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

- Premium Sport Style Safety Boots for Bulk Orders

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

People Also Ask

- How long can you wear safety boots? The Lifespan is Determined by Wear, Not Time

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- What do heavy duty boots do? Protect Your Feet in Demanding Work Environments

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- Is safety-toe as good as steel toe? Choose the Right Protection for Your Job