At its core, the outsole of a road touring boot is your primary interface for control, safety, and comfort. It is engineered to provide unwavering grip on both your footpegs and the ground, absorb fatiguing vibrations from the motorcycle, and offer stable footing when you come to a stop, even in adverse weather conditions.

The ultimate purpose of the outsole is to resolve a fundamental conflict: it must be rigid enough to provide support and protection, yet flexible enough to absorb vibration and allow for comfortable movement. This balance is what separates a mediocre boot from an exceptional one.

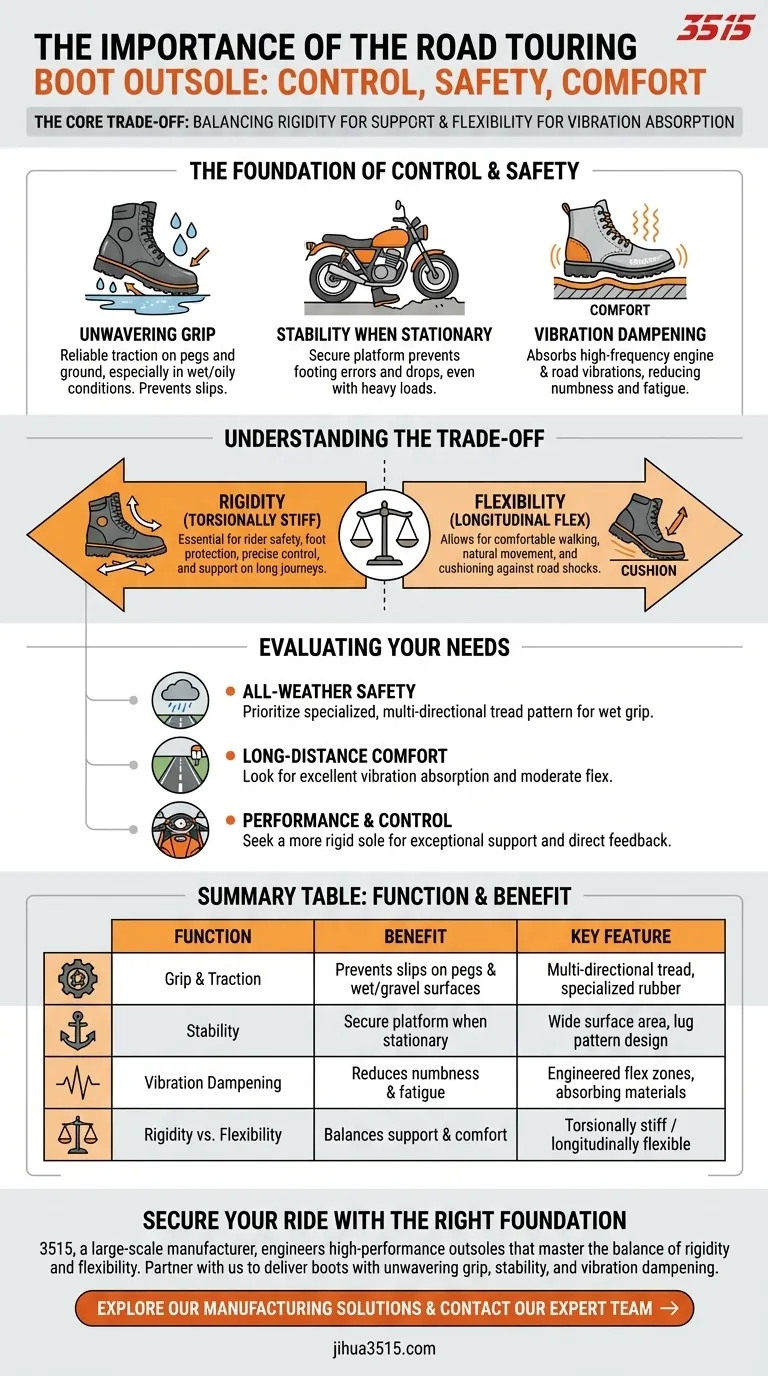

The Foundation of Control and Safety

The outsole is far more than a simple layer of rubber; it is an engineered component directly responsible for your connection to the motorcycle and the road.

Ensuring Unwavering Grip

The most critical function of the outsole is providing reliable traction. This applies to keeping your feet securely on the pegs during a long ride and, just as importantly, preventing slips on the ground.

A well-designed outsole uses specific rubber compounds and tread patterns to maintain grip on wet asphalt, oily patches at intersections, or uneven gravel at a scenic overlook.

Providing Stability When Stationary

A motorcycle is heaviest and most vulnerable to a drop when it's stationary. The outsole's design, including its surface area and lug pattern, is crucial for providing a stable platform.

This stability prevents the kind of footing error that can lead to an injury or a damaged bike, especially when maneuvering a fully-loaded touring machine.

Managing Engine and Road Vibrations

Over hundreds of miles, the constant, high-frequency vibrations transferred through the footpegs can lead to numbness and significant fatigue.

The outsole is the first line of defense, designed to absorb and dampen these vibrations before they reach your feet, dramatically improving long-distance comfort.

Understanding the Core Trade-off: Rigidity vs. Flexibility

The central engineering challenge for any touring boot outsole is finding the perfect equilibrium between two opposing, yet equally important, characteristics.

The Need for Rigidity

A torsionally stiff sole is essential for rider safety and support. It protects your foot from twisting forces in an accident and prevents it from flexing unnaturally over the footpeg.

This rigidity also allows for more precise control inputs and reduces foot muscle fatigue on multi-day journeys.

The Necessity of Flexibility

At the same time, the boot must have enough longitudinal flex to be comfortable. This allows for natural movement when walking off the bike and helps cushion the ride.

Without this flexibility, the boot would feel harsh and unforgiving, transferring every minor shock directly to the rider.

How to Evaluate an Outsole for Your Needs

When choosing a boot, analyze the outsole based on its intended function and your specific riding style.

- If your primary focus is all-weather safety: Prioritize an outsole with a distinct, multi-directional tread pattern engineered for excellent grip in wet conditions.

- If your primary focus is long-distance comfort: Look for a sole with a reputation for excellent vibration absorption and a moderate flex for comfort during fuel stops and short walks.

- If your primary focus is performance and control: Seek a more rigid sole that provides exceptional support and direct feedback from the pegs, even if it slightly compromises off-bike walking comfort.

Ultimately, selecting the right outsole means securing your connection to both the machine and the road, ensuring every mile is as safe as it is comfortable.

Summary Table:

| Function | Benefit | Key Feature |

|---|---|---|

| Grip & Traction | Prevents slips on pegs and wet/gravel surfaces | Multi-directional tread pattern, specialized rubber compound |

| Stability | Provides a secure platform when stationary, preventing drops | Wide surface area, lug pattern design |

| Vibration Dampening | Reduces foot numbness and fatigue on long rides | Engineered flex zones, vibration-absorbing materials |

| Rigidity vs. Flexibility | Balances support for control with comfort for walking | Torsionally stiff for safety, longitudinally flexible for comfort |

Secure Your Ride with the Right Foundation

As a large-scale manufacturer, 3515 produces a comprehensive range of high-performance footwear for distributors, brand owners, and bulk clients. Our advanced production capabilities allow us to engineer outsoles that master the critical balance between rigidity for control and flexibility for comfort.

We help our partners deliver boots that provide the unwavering grip, stability, and vibration dampening that touring riders demand. Let's discuss how we can manufacture the perfect touring boots for your customers.

Contact our expert team today to explore our manufacturing solutions and elevate your product line.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

People Also Ask

- What role does the midsole play in outdoor shoes? Your Guide to Cushioning, Support & Stability

- What safety features are incorporated into motorcycle boots? Essential Protection for Riders

- What are the key considerations when choosing motorcycle boots? Find Your Perfect Fit for Safety & Style

- Which areas of the foot are most vulnerable to snake bites when wearing cowboy boots? The Critical Weak Spot Revealed

- What is the flex scale for hunting boots? Match Your Boot to Your Terrain for Optimal Performance

- What factors should hunters consider when choosing backcountry hunting boots? Find Your Perfect Match for the Hunt

- What is the purpose of the lining in outdoor shoes? Unlock the Secret to All-Day Comfort

- Are there budget-friendly options for winter cycling boots? Understanding the Trade-Offs