At its core, slip resistance in a work boot is a critical safety feature designed to prevent falls. It provides essential grip and stability on surfaces contaminated with water, oil, grease, or chemicals, which are common hazards across countless industries.

The primary function of a slip-resistant boot is to maintain secure footing in unpredictable environments. This is achieved through specialized outsole materials and tread patterns that actively channel away liquids and maximize surface contact, significantly reducing the risk of a career-ending injury.

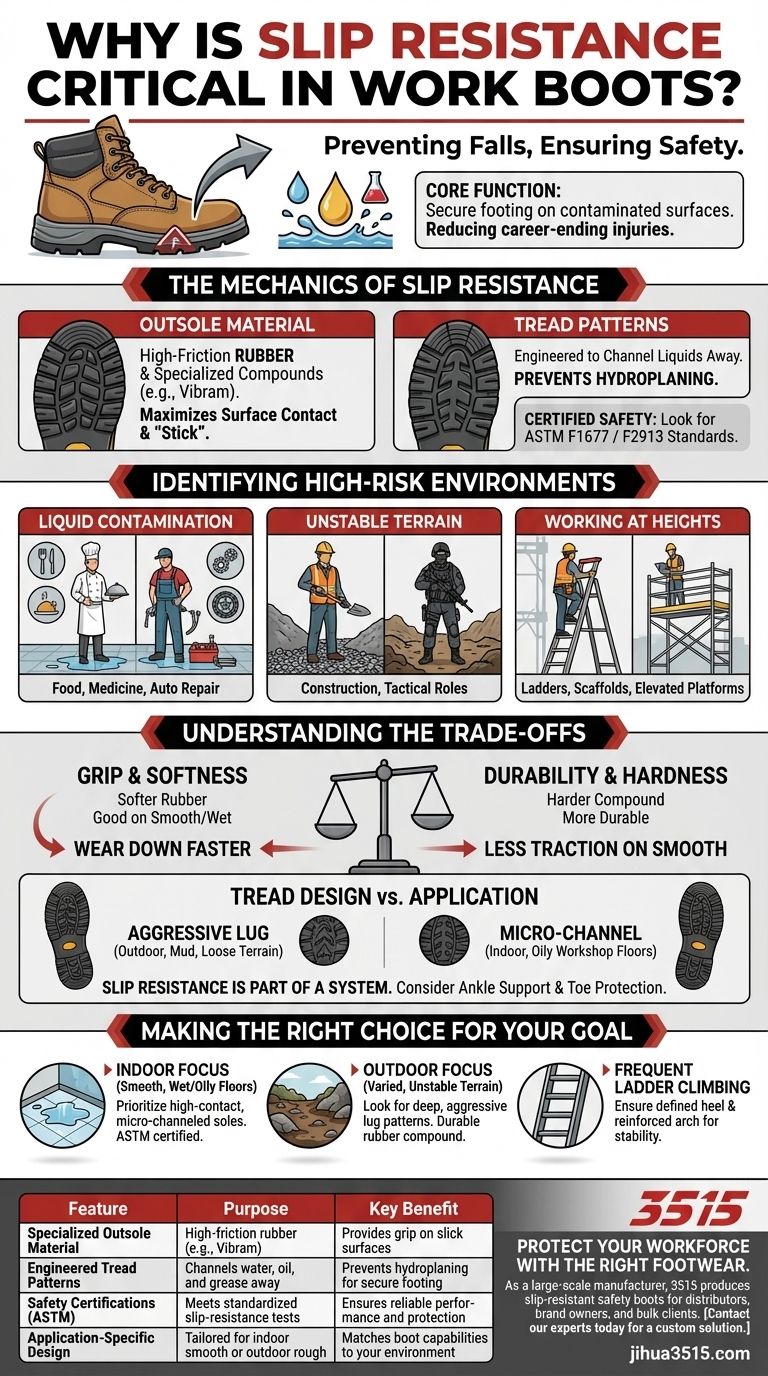

The Mechanics of a Slip-Resistant Boot

True slip resistance is not a single feature but an engineered system. The outsole of the boot is where the most critical design elements come into play.

The Role of the Outsole Material

The material of the outsole is the foundation of grip. High-quality rubber or specialized compounds like Vibram are chosen for their high coefficient of friction, which allows them to effectively "stick" to slick surfaces.

Tread Patterns and Surface Contact

The design of the tread, or lug pattern, is equally important. These patterns are not just for style; they are engineered to channel liquids like water and oil away from the bottom of the boot. This prevents a layer of liquid from forming between the sole and the floor, a phenomenon known as hydroplaning.

Meeting Certified Safety Standards

To ensure a boot provides reliable protection, look for official safety ratings. The most common standards in the United States are the ASTM F1677-2005 (SATRA TM144) and ASTM F2913-19 tests, which certify a boot's performance on slippery surfaces.

Identifying High-Risk Environments

While beneficial for nearly any job, slip resistance becomes non-negotiable in certain conditions where the risk of a fall is dramatically higher.

Surfaces with Liquid Contamination

The most obvious need is in workplaces where floors are frequently wet or oily. This includes industries like food service, medicine, plumbing, and automotive repair, where spills are a daily reality.

Unstable or Uneven Terrain

For workers on construction sites or in tactical roles, the ground is rarely flat or predictable. Deep, aggressive lug patterns provide the traction needed to maintain footing on loose dirt, gravel, or debris.

Working at Heights

The danger of a slip is amplified when working on a ladder, scaffold, or other elevated surface. A slip in these situations can easily lead to a catastrophic fall, making a secure grip an absolute necessity.

Understanding the Trade-offs

No single boot is perfect for every situation. Understanding the inherent trade-offs in outsole design is key to selecting the right tool for the job.

Sole Hardness vs. Grip

A softer rubber compound often provides superior grip on smooth, wet surfaces like tile but may wear down more quickly. A harder compound will be more durable but might offer less traction on those same surfaces.

Tread Design vs. Application

An aggressive, deep-lugged sole is excellent for mud and loose terrain but can be less effective and even trap debris on flat indoor surfaces. Conversely, a sole with many fine channels is ideal for oily workshop floors but would be inadequate outdoors.

Slip Resistance is Part of a System

A slip-resistant outsole is just one component. The boot must also provide the right ankle support, toe protection, and resistance to water or chemicals to be truly effective for your specific work environment.

Making the Right Choice for Your Goal

Selecting the right boot requires matching its features to your primary work environment and the specific hazards you face.

- If your primary focus is working indoors on smooth, wet, or oily floors: Prioritize boots with a high-contact, micro-channeled sole and a certified ASTM slip-resistance rating.

- If your primary focus is working outdoors on varied or unstable terrain: Look for boots with deep, aggressive lug patterns made from a durable rubber compound like Vibram.

- If your primary focus is frequent ladder climbing: Ensure the boot has a defined heel and a reinforced arch for stability, in addition to a reliable slip-resistant sole.

Ultimately, choosing a work boot with the appropriate slip resistance is a direct investment in your personal safety and on-the-job effectiveness.

Summary Table:

| Feature | Purpose | Key Benefit |

|---|---|---|

| Specialized Outsole Material | High-friction rubber (e.g., Vibram) | Provides grip on slick surfaces |

| Engineered Tread Patterns | Channels water, oil, and grease away | Prevents hydroplaning for secure footing |

| Safety Certifications (ASTM) | Meets standardized slip-resistance tests | Ensures reliable performance and protection |

| Application-Specific Design | Tailored for indoor smooth floors or outdoor rough terrain | Matches the boot's capabilities to your work environment |

Protect your workforce with the right footwear. As a large-scale manufacturer, 3515 produces a comprehensive range of slip-resistant safety boots and work footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, engineered to meet specific safety standards like ASTM for superior grip and durability. Let us help you equip your team with the right protection. Contact our experts today for a consultation and custom solution.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- Is safety-toe as good as steel toe? Choose the Right Protection for Your Job

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- What do heavy duty boots do? Protect Your Feet in Demanding Work Environments