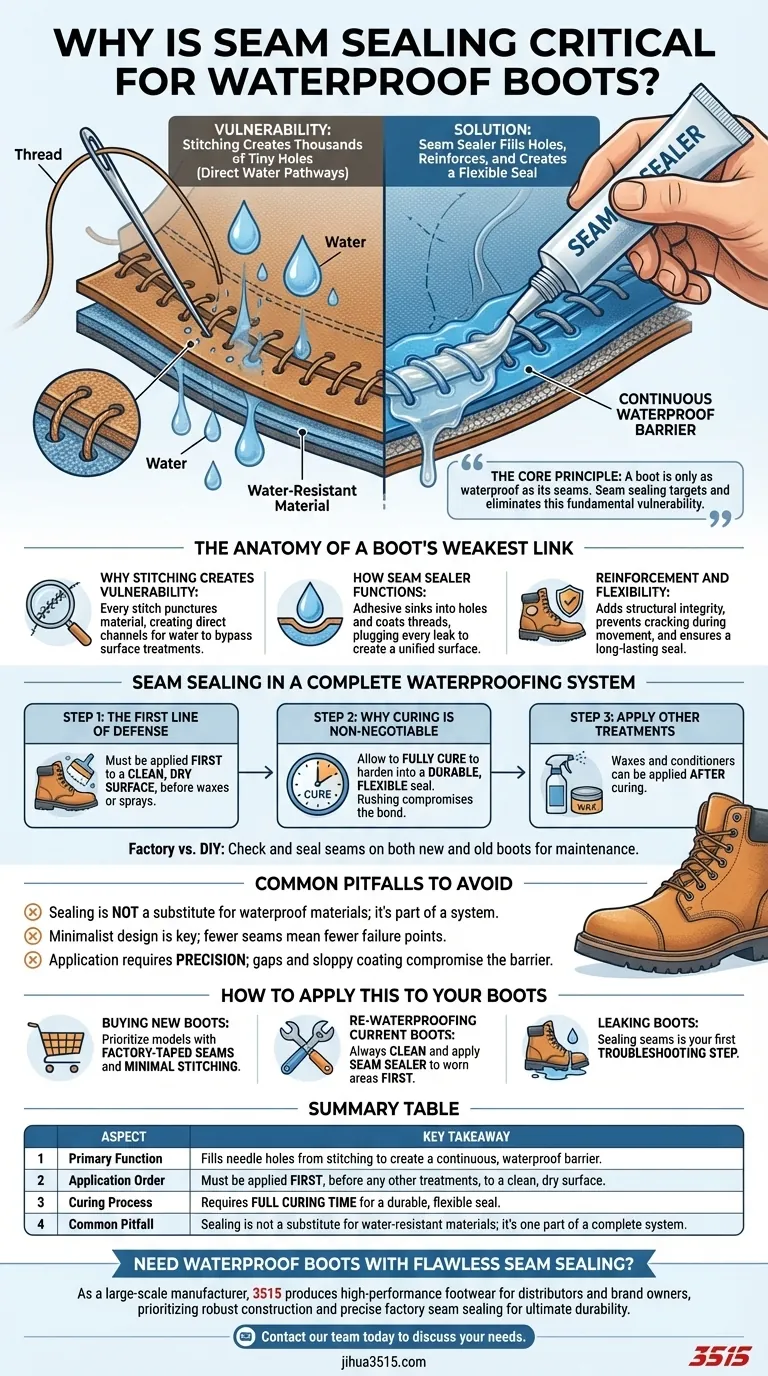

Seam sealing is the most critical step in waterproofing a boot because seams are the primary point of failure. While the leather or fabric of a boot might be water-resistant, the process of stitching panels together creates thousands of tiny holes. A seam sealer, typically a flexible urethane-based adhesive, fills these holes to create a continuous, waterproof barrier, reinforcing the boot's weakest spots against moisture.

The core principle is simple: a boot is only as waterproof as its seams. Even with high-tech materials, the needle holes from stitching create direct pathways for water to enter, and seam sealing is the only process that specifically targets and eliminates this fundamental vulnerability.

The Anatomy of a Boot's Weakest Link

To understand why seam sealing is so vital, you must first understand why a seam fails. It’s not about the material, but the construction.

Why Stitching Creates Vulnerability

Every stitch that holds a boot together punctures the material. This creates a small but direct channel for water to seep from the outside in, completely bypassing the waterproof properties of the leather or fabric.

How Seam Sealer Functions

A seam sealer is an adhesive applied directly over the stitching. It sinks into the needle holes and coats the threads, effectively plugging every potential leak. This turns a series of individual, vulnerable points into a single, unified, and sealed surface.

Reinforcement and Flexibility

Beyond just blocking water, seam sealers add structural integrity. They reinforce these high-stress areas while remaining flexible, ensuring the waterproof barrier doesn't crack or pull apart as your foot flexes and the boot moves.

Seam Sealing in a Complete Waterproofing System

Seam sealing isn't an isolated task; it's the foundation upon which other waterproofing treatments are built. Its timing and application are crucial for success.

The First Line of Defense

Seam sealer must be applied first, before any other waxes, sprays, or conditioning treatments. It requires a clean, dry surface to bond properly. Applying other products first will prevent the sealer from adhering correctly, rendering it ineffective.

Why Curing is Non-Negotiable

After application, the sealer must be allowed to fully cure as directed by the manufacturer. This process allows it to harden into a durable, flexible seal. Rushing this step or applying other treatments on top of an uncured sealer will compromise the bond and lead to failure.

Factory vs. DIY Sealing

Many high-quality waterproof boots come with "sealed" or "taped" seams directly from the factory. However, this seal can wear down over time. Whether you are treating new boots that lack this feature or maintaining old ones, the principle of checking and sealing the seams remains the same.

Common Pitfalls to Avoid

Simply applying a sealer isn't a guarantee. Understanding its limitations is key to achieving a truly waterproof result.

Sealing is Not a Substitute for Waterproof Materials

Seam sealing only addresses the seams. If the primary material of your boot—such as untreated canvas or porous leather—is not water-resistant, the boot will still become saturated with water. Sealing is one part of a complete waterproofing system.

The Importance of Minimalist Design

The best waterproof boots are often designed with minimal stitching. Fewer seams mean fewer potential points of failure from the start, making the boot inherently more water-resistant and easier to maintain.

Application Requires Precision

A sloppy or incomplete application will leave gaps for water to penetrate. Ensuring the entire seam is cleaned and evenly coated is essential for creating a truly impassable barrier.

How to Apply This to Your Boots

Your approach depends on your specific goal, whether you're buying new gear or maintaining what you have.

- If you are buying new boots for wet conditions: Prioritize models that are advertised with factory-taped or sealed seams and feature designs with minimal external stitching.

- If you are re-waterproofing your current boots: Always begin by cleaning and inspecting the seams, applying a quality seam sealer to any worn areas before using any other waterproofing product.

- If your "waterproof" boots are leaking: The seams are the most likely culprit; sealing them should be your first and most important troubleshooting step.

By addressing the seams first, you are fortifying your boots at their most fundamental point of failure.

Summary Table:

| Aspect | Key Takeaway |

|---|---|

| Primary Function | Fills needle holes from stitching to create a continuous, waterproof barrier. |

| Application Order | Must be applied first, before any other waterproofing treatments, to a clean, dry surface. |

| Curing Process | Requires full curing time as per manufacturer instructions to ensure a durable, flexible seal. |

| Common Pitfall | Sealing is not a substitute for water-resistant materials; it's one part of a complete system. |

Need Waterproof Boots with Flawless Seam Sealing?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-performance footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of waterproof boots, where we prioritize robust construction and precise factory seam sealing to ensure ultimate durability and protection for your customers.

Let us help you build a better product. Contact our team today to discuss your specific needs and how our manufacturing expertise can bring value to your business.

Visual Guide

Related Products

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- High Performance Fire-Retardant Waterproof Safety Boots

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

People Also Ask

- Why is it necessary to equip operators with professional safety shoes in a flour milling workshop? Prevent Slip Hazards

- Why is hydrophobic waterproof leather commonly utilized in the construction of fire safety boots? Essential Protection

- What protective functions do industrial safety shoes provide for utility technicians? Stability & Electrical Insulation

- Why is the use of professional safety shoes critical for injection molding? Prevent Injuries with High-Impact Footwear

- What protective functions do industrial safety shoes provide in petroleum environments? Secure Your Workers' Health