At its core, PVC resin is the fundamental building block that gives a rain boot its essential character. It is the base polymer that, when combined with other additives, creates a material that is waterproof, durable, and resistant to the elements, directly defining the boot's quality and lifespan.

The importance of PVC resin isn't just its inherent properties, but its role as a "blank canvas." The final performance of a rain boot depends entirely on how this base resin is modified with additives like plasticizers and stabilizers to achieve the perfect balance of flexibility and durability.

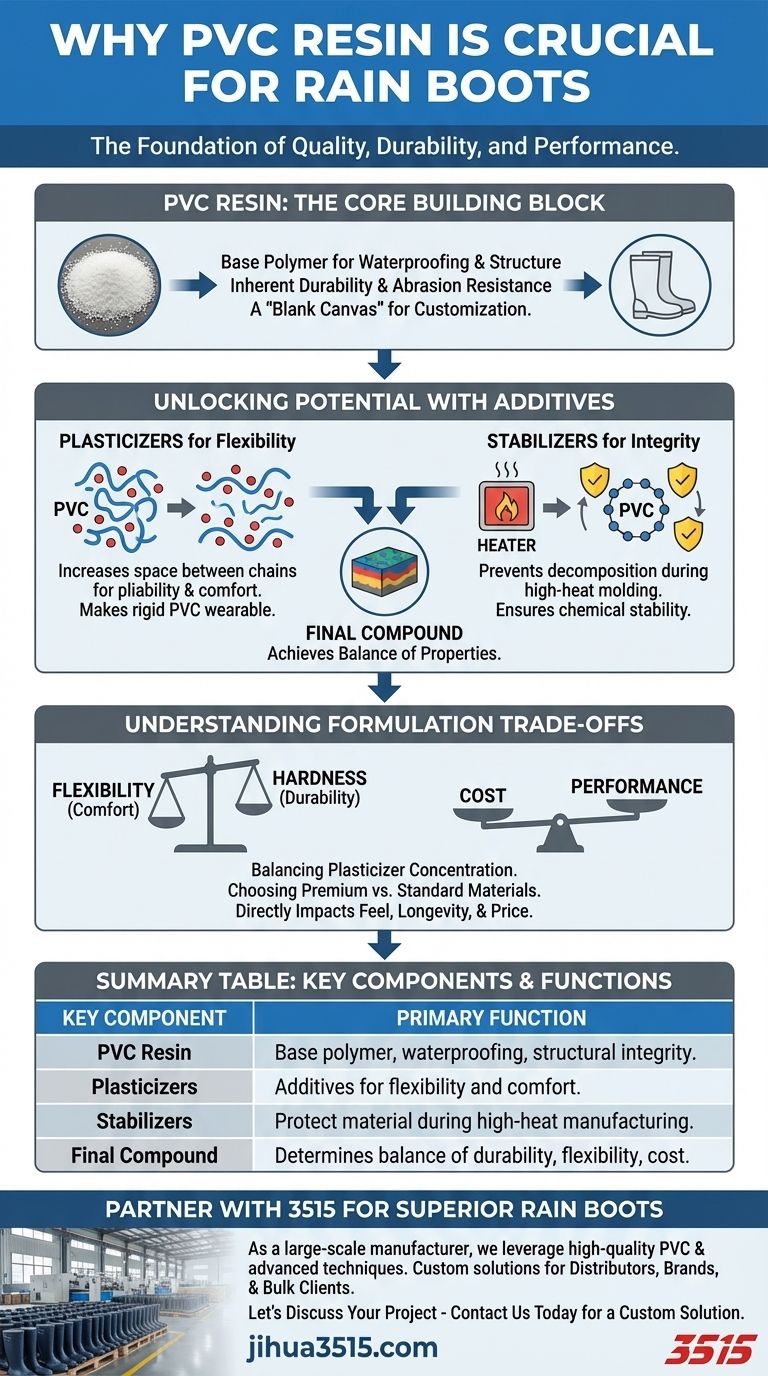

The Role of PVC Resin as the Core Material

Polyvinyl chloride (PVC) resin is the starting point for the entire manufacturing process. It provides the essential structure and foundational properties that make a rain boot effective against wet conditions.

Inherent Durability and Waterproofing

PVC is naturally waterproof. Its molecular structure creates an impermeable barrier to water, which is the primary requirement for any rain boot. The resin also provides excellent resistance to abrasion and general wear, forming a tough outer shell.

A Foundation for Customization

In its pure, unprocessed state, PVC resin is a rigid and brittle powder. It cannot be used for footwear directly. Its true value lies in its ability to be blended with various additives to create a compound with specific, desirable properties tailored for a final product like a flexible boot.

How Additives Unlock PVC's Potential

While PVC resin forms the base, it's the precise "recipe" of additives that transforms it from a rigid plastic into a comfortable and long-lasting boot. Each ingredient plays a critical role.

Plasticizers for Flexibility

To make the rigid PVC pliable and comfortable to wear, plasticizers are mixed in. These additives work their way between the PVC polymer chains, increasing the space between them and allowing them to slide past one another. This is what gives the final boot its essential flexibility.

Stabilizers for Manufacturing Integrity

The process of melting and molding PVC generates significant heat. According to the provided materials, stabilizers are crucial because they prevent the PVC resin from decomposing or burning during this high-temperature processing. This ensures the material's chemical structure remains intact, leading to a stable and reliable final product.

Achieving Chemical Resistance

The combination of the stable PVC polymer and its protective additives results in excellent chemical resistance. This makes the boots resilient not just to water, but also to salts, mild acids, and other common substances encountered outdoors, preventing the material from degrading over time.

Understanding the Trade-offs in Formulation

The specific blend of PVC resin and additives is a careful balancing act. The choices made during compounding directly impact the final product's feel, performance, and cost.

Flexibility vs. Hardness

The amount of plasticizer used is a critical trade-off. A higher concentration results in a softer, more flexible boot that is comfortable for walking. However, too much can compromise durability and foot support. A lower concentration creates a harder, more rigid boot that may be more durable but less comfortable.

Cost vs. Performance

The quality of the PVC resin and the additives used significantly influences the boot's cost and long-term performance. Using premium, high-purity resin and advanced stabilizers leads to a more durable, longer-lasting product but increases manufacturing costs. Cheaper formulations may degrade more quickly when exposed to sunlight or chemicals.

How This Impacts Your Choice

Understanding the role of PVC resin helps you evaluate rain boots based on their intended use.

- If your primary focus is everyday comfort and casual use: You are looking for a boot made from a well-balanced PVC compound that prioritizes flexibility.

- If your primary focus is heavy-duty work or maximum longevity: You need a boot formulated for durability, likely with a tougher PVC compound that includes high-quality stabilizers for long-term integrity.

Ultimately, the quality of the PVC resin and its formulation is the hidden factor that determines whether a rain boot will protect you for a single season or for years to come.

Summary Table:

| Key Component | Primary Function |

|---|---|

| PVC Resin | Base polymer providing waterproofing and structural integrity. |

| Plasticizers | Additives that increase flexibility and comfort. |

| Stabilizers | Protect the material during high-temperature manufacturing. |

| Final Compound | Determines the boot's balance of durability, flexibility, and cost. |

As a large-scale manufacturer, 3515 leverages high-quality PVC resin and advanced compounding techniques to produce superior rain boots. Whether you are a distributor, brand owner, or bulk client, our expertise ensures your footwear meets exact specifications for durability, comfort, and cost-effectiveness. We produce a comprehensive range of boots for all applications. Let's discuss your project – contact our team today for a custom solution.

Visual Guide

Related Products

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Wholesale High-Traction Camo Boots - Custom Manufacturer for Brands

People Also Ask

- Can wellies be washed in a washing machine? Avoid Costly Damage to Boots & Machine

- What should adults consider when buying wellington boots? Find the Perfect Fit for Your Needs

- How can wellies be styled for different occasions? Master Rainy Day & Festival Fashion

- What are the benefits of wearing Wellington boots in winter? Stay Dry and Warm in Wet Conditions

- What are the benefits and drawbacks of neoprene-lined wellington boots? A Guide to Cold-Weather Footwear

- What happens if you neglect cleaning rubber boots? Protect Your Investment from Premature Failure

- What are the two main materials used to make wellington boots? Rubber vs. PVC Explained

- Why are wellies recommended for parents at sports events? Stay Dry and Comfortable on the Sidelines