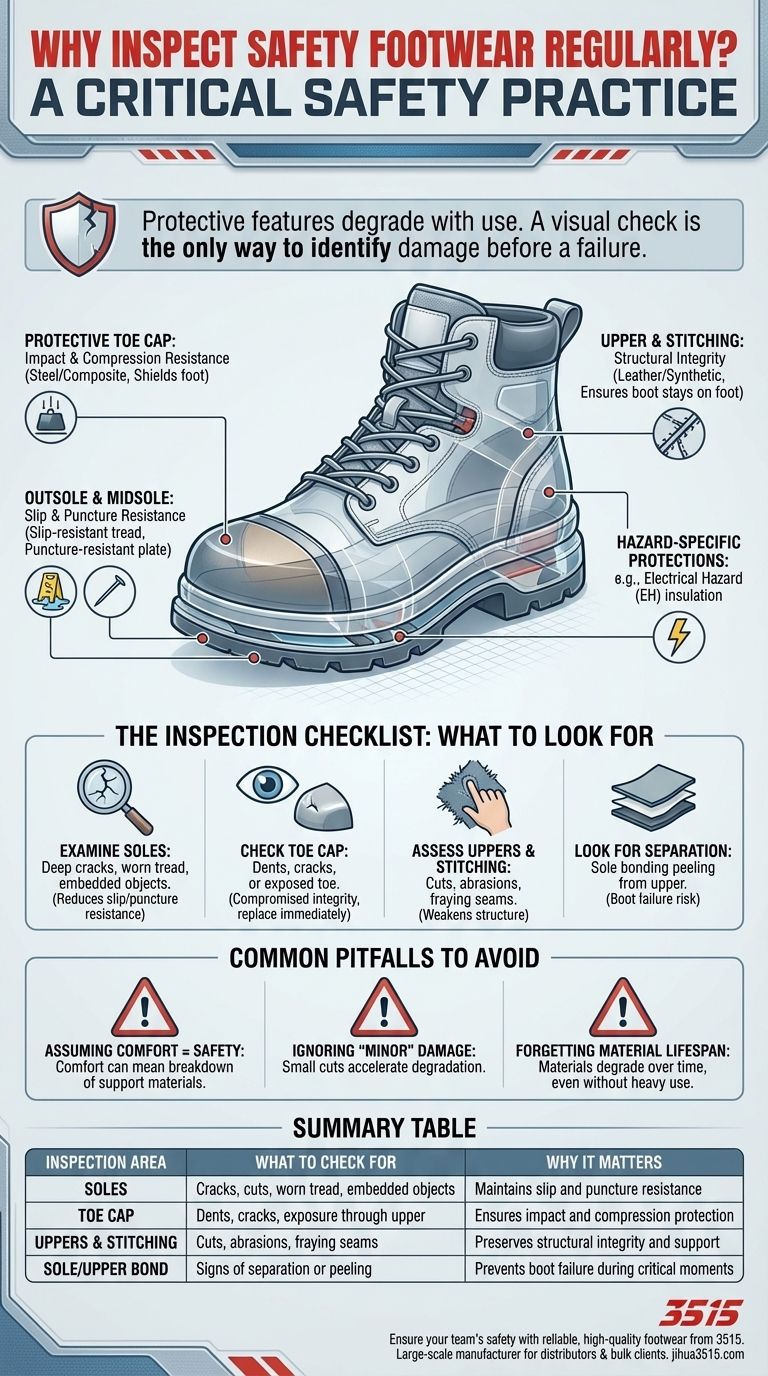

Regular inspection of safety footwear is a critical safety practice because the protective features that make the footwear effective degrade with use. A visual check is the only way to identify damage like cracks in the sole, separation between the sole and the upper, or an exposed safety toe, any of which can lead to a complete failure of protection during an incident.

The core purpose of safety footwear is to prevent injury in a hazardous environment. Since this protection is not permanent and erodes with wear and tear, regular inspection is the essential process that ensures the equipment remains capable of performing its function.

The Anatomy of Protection in Safety Footwear

To understand what to look for during an inspection, you must first understand what makes safety footwear "safe." These are not just sturdy boots; they are engineered systems designed to meet specific standards for protection.

Impact and Compression Resistance

The most recognized feature is the protective toe cap, typically made of steel or composite materials.

This component is designed to shield the foot from falling objects (impact) and crushing forces (compression). OSHA standards mandate a rating of 75, meaning it can withstand 75 foot-pounds of impact and 2,500 pounds of compression.

Sole and Puncture Resistance

The outsole of the boot provides slip resistance on various surfaces and may offer protection against specific hazards like oil.

Some boots also include a puncture-resistant plate in the midsole to protect against sharp objects like nails piercing through from below.

Hazard-Specific Protections

Safety footwear is often rated for specific environmental dangers.

This includes Electrical Hazard (EH) protection, which insulates the wearer from the ground to prevent shock, or conductive properties to prevent static discharge in sensitive environments.

Structural Integrity

The overall construction, including the leather or synthetic upper, stitching, and lacing system, ensures the boot stays on the foot and provides necessary ankle and arch support. This structural integrity is vital for the other safety systems to function correctly.

The Inspection Checklist: What to Look For

A quick but thorough inspection can be the difference between a close call and a serious injury. This check should become a routine part of preparing for work.

Examine the Soles

Look for deep cracks, cuts, or embedded objects that could compromise puncture resistance.

Check the tread depth. If the tread pattern is worn smooth, the boot's slip-resistance is significantly reduced and it should be replaced.

Check the Toe Cap

Visually inspect the toe area for any signs of dents, cracks, or damage.

If the toe cap becomes visible or exposed through the upper material, the boot's integrity is compromised and it must be taken out of service immediately.

Assess the Uppers and Stitching

Inspect the leather or synthetic material for deep cuts, abrasions, or chemical damage that could weaken the structure.

Check all seams and stitching. Fraying or separating seams indicate the boot is losing its structural integrity.

Look for Separation

Pay close attention to the area where the sole is bonded to the upper part of the boot.

Any sign of separation or peeling means the boot is failing and could easily come apart, offering no protection when needed.

Common Pitfalls to Avoid

Simply owning safety footwear is not enough. Misunderstanding its limitations and life cycle can create a false sense of security.

Assuming Comfort Equals Safety

A boot may become more comfortable as it wears in, but this is often a sign that supportive materials and shock-absorbing structures are breaking down.

Comfort should never be prioritized over the integrity of the boot's protective features.

Ignoring "Minor" Damage

A small cut in the upper or a minor crack in the sole may seem insignificant.

However, these small points of failure can allow moisture or chemicals to penetrate the boot, accelerating its degradation and leading to sudden failure.

Forgetting About Material Lifespan

All materials degrade over time, even without heavy use. Glues, polymers in the sole, and leather can become brittle and lose their protective properties.

Footwear has a finite lifespan and should be replaced according to manufacturer guidelines or when signs of degradation appear, whichever comes first.

Making the Right Choice for Your Goal

Integrating regular inspection into your safety protocol is a simple but powerful action. Your approach can be tailored to your specific role and responsibilities.

- If your primary focus is personal safety: Treat your boots like any other critical tool and perform a quick visual inspection before each shift for any of the failure points mentioned above.

- If your primary focus is team compliance: Implement a formal, documented inspection policy and provide clear training so all employees know what to look for and when to request a replacement.

- If your primary focus is maximizing equipment value: Emphasize proper care, cleaning, and storage, as this prevents premature material degradation and extends the functional life of the footwear.

Consistent inspection transforms safety footwear from a simple compliance item into a reliable shield against workplace injury.

Summary Table:

| Inspection Area | What to Check For | Why It Matters |

|---|---|---|

| Soles | Cracks, cuts, worn tread, embedded objects | Maintains slip and puncture resistance |

| Toe Cap | Dents, cracks, exposure through upper | Ensures impact and compression protection |

| Uppers & Stitching | Cuts, abrasions, fraying seams | Preserves structural integrity and support |

| Sole/Upper Bond | Signs of separation or peeling | Prevents boot failure during critical moments |

Ensure your team's safety with reliable, high-quality footwear from 3515. As a large-scale manufacturer, we produce a comprehensive range of safety boots and shoes for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of protective footwear designed to meet rigorous safety standards. Don't compromise on protection—contact us today to discuss your specific needs and secure durable, compliant safety footwear for your workforce.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Premium Suede Metatarsal Guard Safety Boots Work Shoes

People Also Ask

- What are the main safety features of composite-toe boots? Essential Protection for High-Risk Jobs

- Who can benefit from using composite toe boots? Lightweight, Non-Conductive Safety for Modern Trades

- What do the markings on ASTM-compliant safety shoes indicate? Decode the Safety Labels for Maximum Protection

- What occupational hazards does industrial Safety Footwear address in high-risk environments? Essential Lab Safety Guide

- How does lightweight safety shoe technology reduce waist and shoulder injuries? Expert Ergonomic Insights

- How do safety shoes with anti-slip soles contribute to gait stability? Master Traction for Fall Prevention

- What materials are used in safety shoes? A Guide to Protective Footwear Construction

- Why wear puncture-resistant shoes for fiber optic cable installation? Protect against ceiling space hazards.