Those markings on your safety shoes are a standardized code, a language that communicates exactly what hazards the footwear is designed to protect you from. Governed by standards like ASTM F2413, this code details the shoe's certified resistance to impact, compression, electrical shock, and other specific workplace dangers.

The ASTM F2413 label on a safety shoe is a concise summary of its protective capabilities. Understanding this code is not just about compliance; it's about matching your equipment directly to the specific hazards you face, ensuring your personal protective equipment is truly personal and protective.

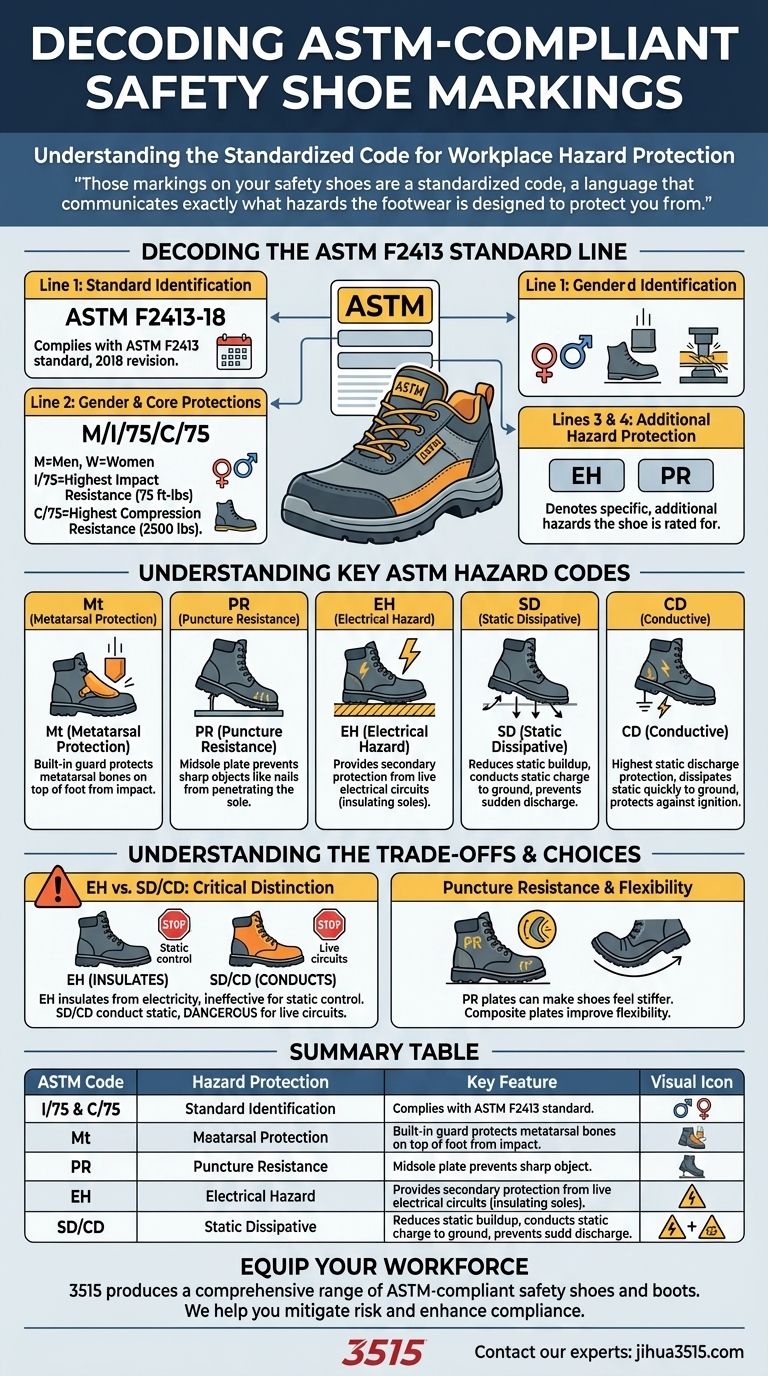

Decoding the ASTM F2413 Standard Line

The information on a certified safety shoe's tag is presented in a specific, multi-line format. Each line provides a distinct piece of information about its compliance and capabilities.

Line 1: The Standard Identification

The first line identifies the standard the shoe meets. For example, ASTM F2413-18.

This indicates the shoe complies with the ASTM International standard F2413. The "-18" signifies the year of the standard's revision, in this case, 2018.

Line 2: Gender and Core Protections

The second line specifies the gender the shoe is designed for and its rating for impact and compression resistance. It will look like M/I/75/C/75.

- M or W: Denotes whether the footwear is designed for Men or Women.

- I/75: Indicates the shoe meets the highest standard for Impact resistance (75 foot-pounds).

- C/75: Indicates the shoe meets the highest standard for Compression resistance (withstanding 2,500 pounds).

Lines 3 & 4: Additional Hazard Protection

Any subsequent lines on the label denote the specific, additional hazards the shoe is rated to protect against. This is where you find the codes for more specialized protection.

Understanding Key ASTM Hazard Codes

While impact and compression are foundational, specialized roles require protection against other dangers. The following are the most common codes you will find on the label.

Mt: Metatarsal Protection

The Mt rating signifies that the shoe has a built-in guard that protects the metatarsal bones on the top of your foot from impact. This is crucial in environments where objects could be dropped on the foot.

PR: Puncture Resistance

A PR rating means the footwear has a puncture-resistant plate built into the midsole. This is designed to prevent sharp objects like nails or metal shards from penetrating the sole of the shoe.

EH: Electrical Hazard

Footwear marked with EH is designed to provide a secondary source of protection from live electrical circuits. The soles are made from a non-conductive material that can significantly reduce the potential for electric shock.

SD: Static Dissipative

SD rated footwear is designed to reduce the buildup of static electricity on your body. These shoes conduct static charge from the body to the ground, preventing a sudden discharge that could damage sensitive electronic equipment.

CD: Conductive

CD rated footwear offers the highest level of static discharge protection. It is designed to dissipate static electricity from the body into the ground extremely quickly, protecting against static spark ignition of volatile chemicals or explosives.

Understanding the Trade-offs

Choosing the right boot isn't just about finding one with the most codes; it's about understanding how these features interact and what their limitations are.

EH vs. SD/CD: A Critical Distinction

This is the most critical distinction to understand. EH boots insulate you from electricity, while SD and CD boots are designed to conduct static electricity away from you.

Using an EH boot in an environment that requires static control is ineffective. More dangerously, wearing an SD or CD boot when you need protection from live circuits completely negates your protection and dramatically increases your risk of electric shock.

Puncture Resistance and Flexibility

While critical for safety, the puncture-resistant plates required for a PR rating can sometimes make a shoe feel stiffer and less flexible than a standard boot. Modern composite plates have improved this, but it remains a factor to consider for comfort.

Other Common Markings

You may also see markings for features like slip resistance (SRA, SRB, SRC), heat insulation (HI), cold insulation (CI), or water resistance (WR). These are often vital for specific environments and add another layer of protection.

Making the Right Choice for Your Environment

Your specific job hazards dictate the codes you need to look for. Use this as a guide to select the right footwear.

- If your primary focus is working with live electricity: You must select a boot with an EH rating for its insulating properties.

- If your primary focus is preventing static discharge (e.g., electronics manufacturing): Your boot needs an SD or CD rating, and you must never use an EH boot for this task.

- If your primary focus is construction or scrap yards: I/75, C/75, PR, and potentially Mt ratings are your most critical features for protection against impact and punctures.

- If your primary focus is wet or slippery surfaces: Look for WR (water-resistant) and a high slip-resistance rating like SRC.

By understanding this language of safety, you empower yourself to select the precise tool that keeps you safe on the job.

Summary Table:

| ASTM Code | Hazard Protection | Key Feature |

|---|---|---|

| I/75 & C/75 | Impact & Compression | Resists 75 ft-lbs impact & 2,500 lbs compression |

| Mt | Metatarsal | Protects top of foot from heavy impacts |

| PR | Puncture | Midsole plate stops sharp objects |

| EH | Electrical Hazard | Insulates against live circuits |

| SD/CD | Static Dissipative/Conductive | Controls static electricity discharge |

Ensure your workforce is equipped with the right safety footwear.

As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM-compliant safety shoes and boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of protective footwear, ensuring you get the precise combination of safety ratings (like I/75, C/75, PR, EH, Mt) required for your specific work environment.

We help you mitigate risk, enhance compliance, and protect your most valuable asset—your people. Contact our experts today to discuss your bulk safety footwear needs and receive a customized solution.

➡️ Get a Custom Quote for Your Safety Footwear

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Wholesale Leather Safety Boots with Customizable Protective Toe

People Also Ask

- What are the production benefits of choosing modular electronic components for smart protective footwear? Scale Faster

- Why is professional functional protective footwear considered a core component for the prevention of diabetic foot ulcers?

- What is the role of scuffcaps in safety footwear? Extend Your Boot's Lifespan with Durable Protection

- What are the limitations of composite toe boots? A Guide to the Safety Trade-offs

- What are the benefits of waterproofing liners in safety shoes? Achieve Superior Foot Protection & Comfort

- Which traditional manufacturing challenges are addressed by using 3D printing for safety shoe outsoles? Solve Tooling Woes

- What is the necessity of professional safety shoes in hospital nursing? Protect Your Health with Ergonomic Footwear

- What are aramid threads and why are they used in firefighter boots? Essential for Uncompromising Safety