Breaking in new shoes is an essential process of adapting their structure to the unique anatomy of your feet. Many quality footwear materials, particularly leather, are initially rigid and require a period of wear to soften, flex, and mold. This gradual adaptation is the key to transforming a stiff, new shoe into a comfortable, personalized fit that prevents pain and blisters.

The purpose of a "break-in" period is not to fix a shoe that fits poorly, but to allow a correctly sized shoe to conform to your foot's specific contours. It's a critical step that bridges the gap between a generic factory shape and a custom, comfortable fit.

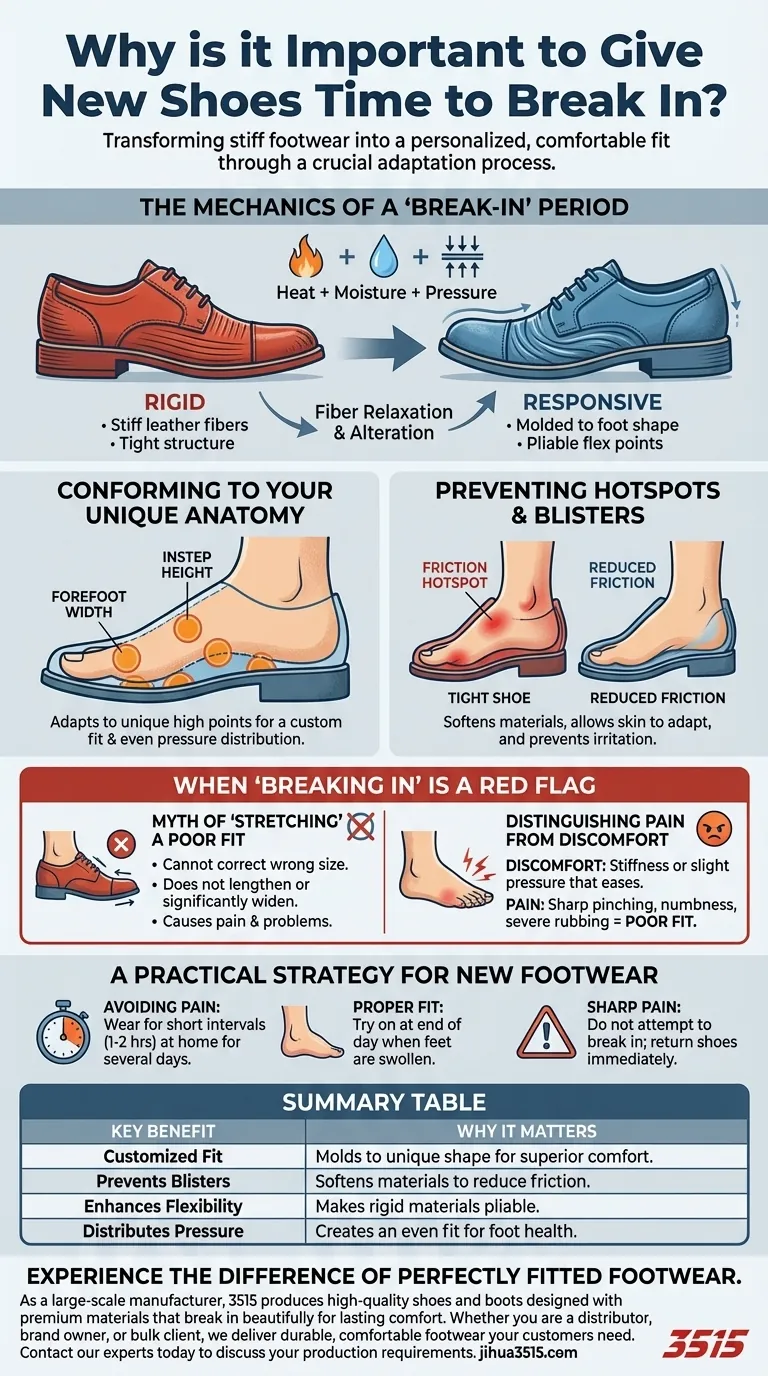

The Mechanics of a "Break-In" Period

The process of breaking in a shoe is a physical interaction between your foot and the shoe's materials. Heat, moisture, and pressure work together to permanently alter the footwear's structure for improved comfort.

From Rigid to Responsive

Materials like full-grain leather are composed of a dense matrix of collagen fibers. Initially, these fibers are tightly bundled, making the material stiff. The combination of your body heat and the repeated flexing motion from walking gradually loosens and relaxes these fibers.

This process allows the material to become more pliable and responsive to your movement, reducing stiffness in key flex points like the toe box and ankle.

Conforming to Your Unique Anatomy

No two feet are identical. A new shoe is built on a standardized form called a "last," which is an approximation of an average foot shape.

The break-in period is when your foot's unique high points—such as the width of your forefoot, the height of your instep, or the curve of your arch—imprint themselves onto the shoe. This creates a more customized fit that distributes pressure evenly.

Preventing Hotspots and Blisters

Friction is the primary cause of blisters. In a new shoe, stiff materials create high-friction "hotspots" where the shoe constantly rubs against a specific part of your foot.

Gradually breaking in the shoes allows the material to soften in these areas, reducing friction. It also gives your skin time to adapt and toughen slightly, providing a dual defense against irritation.

When "Breaking In" is a Red Flag

Understanding the difference between mild stiffness and a fundamentally poor fit is crucial. A break-in period can't fix every problem, and trying to force it can lead to foot damage.

The Myth of "Stretching" a Poor Fit

A break-in period will accommodate mild tightness and stiffness, but it cannot correct a shoe that is the wrong size. If your toes are cramped against the end of the shoe or the width causes sharp pinching, the shoe is too small.

No amount of "breaking in" will lengthen the shoe or significantly widen the sole. You are simply inviting pain and potential foot problems like bunions or hammertoes.

Distinguishing Pain from Discomfort

Initial discomfort is a feeling of stiffness or slight pressure that eases over time. It's a normal part of the process.

Pain, on the other hand, is a warning sign. Sharp pinching, numbness, or immediate and severe rubbing are indicators of a poor fit, not a shoe that needs to be broken in.

A Practical Strategy for New Footwear

Applying the right approach ensures your new shoes become a long-term asset rather than a painful mistake. Use these guidelines to manage the process effectively.

- If your primary focus is avoiding pain: Wear the new shoes for short intervals (1-2 hours) at home for several days before committing to a full day of wear.

- If your primary focus is a proper fit: Try shoes on at the end of the day when your feet are slightly swollen to get the most accurate sense of their true size.

- If you feel sharp pain or numbness: Do not attempt to "break in" the shoe; this is a clear sign of a poor fit, and the shoes should be returned.

Ultimately, breaking in your footwear is about patience and listening to your body to achieve a truly personalized fit.

Summary Table:

| Key Benefit | Why It Matters |

|---|---|

| Customized Fit | Molds to your foot's unique shape for superior comfort. |

| Prevents Blisters | Softens materials to reduce friction and hotspots. |

| Enhances Flexibility | Makes rigid materials like leather pliable and responsive. |

| Distributes Pressure | Creates an even fit that supports foot health. |

Experience the difference of perfectly fitted footwear. As a large-scale manufacturer, 3515 produces a comprehensive range of high-quality shoes and boots designed with premium materials that break in beautifully for lasting comfort. Whether you are a distributor, brand owner, or bulk client, we can deliver the durable, comfortable footwear your customers need. Contact our experts today to discuss your production requirements.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Wholesale Training Shoes with Dial Lacing System Custom OEM Manufacturing

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear

- What are the primary protective functions of professional Safety Boots within the automotive maintenance process?

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- What core protection features do industrial-grade Safety Shoes provide? Key Safety Standards for Infrastructure Sites