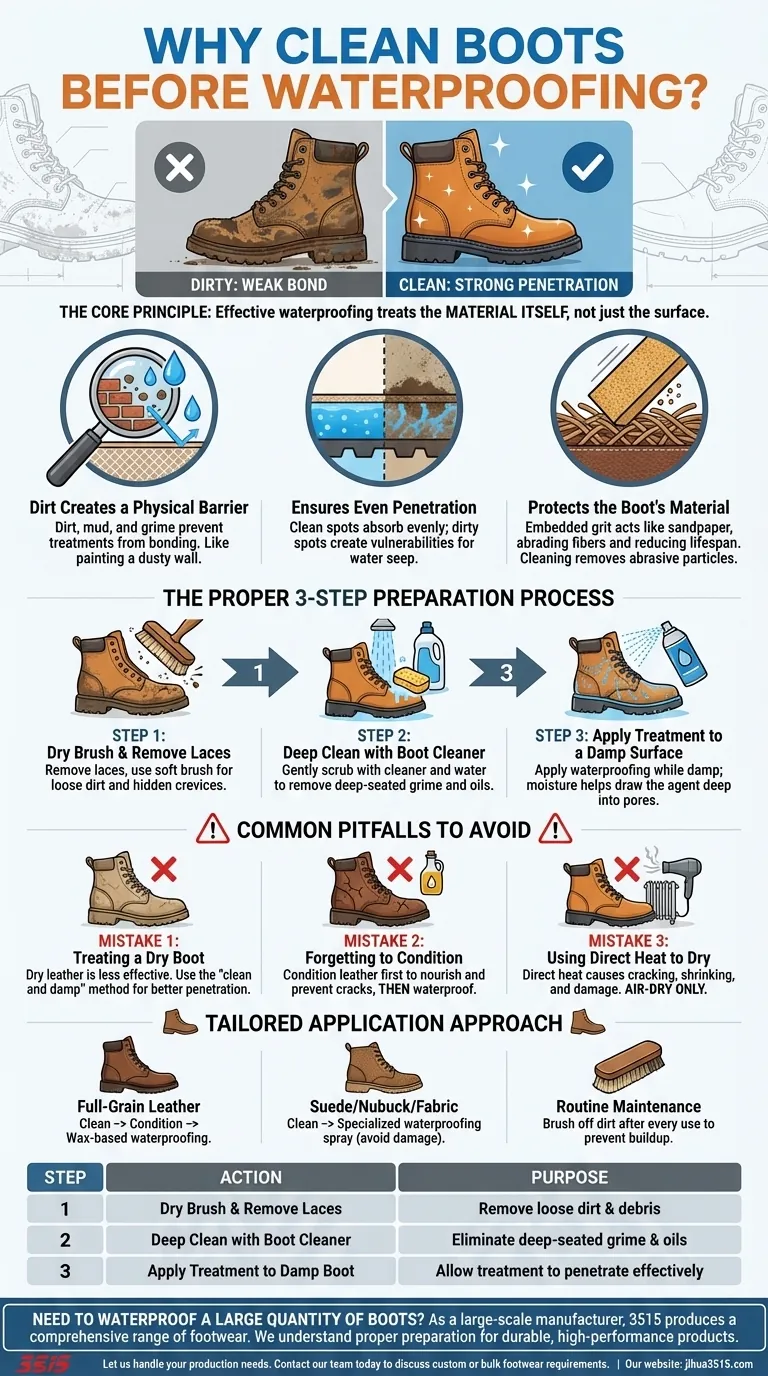

To put it simply, you must clean your boots before waterproofing because dirt, mud, and grime create a physical barrier. This barrier prevents waterproofing treatments from properly bonding with and penetrating the boot's material, leading to a weak, uneven, and short-lived protective layer.

The core principle is this: effective waterproofing isn't about coating your boots, it's about treating the material itself. Cleaning removes the contamination that stands in the way, allowing the treatment to be fully absorbed for maximum durability and performance.

The Core Principle: Why a Clean Surface is Non-Negotiable

Properly preparing your boots is the single most important factor in a successful waterproofing application. Skipping this step essentially guarantees the treatment will fail prematurely.

Dirt Creates a Physical Barrier

Think of trying to paint a dusty wall. The paint sticks to the dust, not the wall, and flakes off easily. The same is true for your boots. Any dirt, oil, or grit on the surface will catch the waterproofing agent, preventing it from reaching the actual leather or fabric that needs protection.

It Ensures Even Penetration

Water finds the path of least resistance. If your boots have clean spots and dirty spots, the waterproofing treatment will be applied unevenly. This creates vulnerabilities where water can easily seep through, defeating the entire purpose of the application.

It Protects the Boot's Material

Embedded grit and dirt act like sandpaper, slowly abrading the fibers of your boots' upper material every time they flex. A thorough cleaning removes these abrasive particles, which helps extend the overall lifespan of your footwear.

The Proper 3-Step Preparation Process

A methodical approach ensures you're not just applying a product, but truly restoring your boot's primary line of defense against moisture.

Step 1: Dry Brush and Remove Laces

First, remove the laces to gain full access to the tongue and all the hidden crevices around the eyelets. Use a soft-bristled brush to knock off all loose dirt, caked-on mud, and dust.

Step 2: Deep Clean with a Boot Cleaner

For a thorough cleaning, use running water and a specialized boot cleaner. Gently scrub the entire boot, paying attention to seams and creases. This removes the deep-seated grime and oils that a dry brush can't.

Step 3: Apply Treatment to a Damp Surface

Most modern waterproofing treatments work best when applied to clean, damp boots. The moisture within the leather or fabric helps to draw the waterproofing agent deep into the material's pores for a much more thorough and lasting bond.

Common Pitfalls to Avoid

Many well-intentioned waterproofing jobs fail because of a few common and easily avoidable mistakes. Being aware of them is critical for success.

Mistake 1: Treating a Dry Boot

While it may seem counterintuitive, applying treatments to bone-dry leather is less effective. As mentioned, a damp surface actively pulls the treatment in. Always check the specific product's instructions, but the "clean and damp" method is the professional standard.

Mistake 2: Forgetting to Condition

For leather boots, conditioning and waterproofing are two different goals. Conditioning uses oils and creams to nourish the leather, keeping it supple and preventing cracks. Waterproofing creates a moisture barrier. For best results, you should clean, then condition, then waterproof.

Mistake 3: Using Direct Heat to Dry

Never place your boots near a radiator, campfire, or use a hairdryer to speed up drying. Intense, direct heat can cause leather to crack, shrink, and can even melt the adhesives holding the boot together. Allow them to air-dry in a well-ventilated area; a simple fan can help circulate air safely.

Applying This to Your Boots

Your approach should be tailored to your footwear's material and your primary goal.

- If your primary focus is restoring full-grain leather boots: Follow a complete process of cleaning, applying a leather conditioner, and then finishing with a wax-based waterproofing product for maximum durability.

- If your primary focus is treating suede, nubuck, or fabric boots: After cleaning, use a specialized waterproofing spray designed for these more delicate materials to avoid damaging their texture.

- If your primary focus is routine maintenance: Get in the habit of brushing off your boots after every use to prevent dirt from building up, making your next full waterproofing session far more effective.

Ultimately, cleaning is not an optional first step; it is the foundation for lasting protection and the longevity of your investment.

Summary Table:

| Step | Action | Purpose |

|---|---|---|

| 1 | Dry Brush & Remove Laces | Remove loose dirt and debris from all surfaces. |

| 2 | Deep Clean with Boot Cleaner | Eliminate deep-seated grime and oils. |

| 3 | Apply Treatment to Damp Boot | Allow treatment to penetrate material effectively. |

Need to waterproof a large quantity of boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, and we understand the importance of proper preparation for durable, high-performance products.

Let us handle your production needs with the same attention to detail required for proper boot care. Contact our team today to discuss your custom or bulk footwear requirements.

Visual Guide

Related Products

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

People Also Ask

- What are cowboy boots and why are they significant? Discover the Anatomy of an Icon

- What is the role of ergonomic workbenches in footwear pattern design? Boost Precision and Protect Artisan Health

- What are the key factors that make a boot waterproof? A Guide to Dry Feet Technology

- What is the necessity of performing multi-point inspections on shoe soles? Ensure Consistency and Safety

- Why is digital blood pressure monitoring necessary in footwear stress tests? Quantifying Cardiovascular Safety

- What role does a professional treadmill play in a central fatigue induction protocol? Precision Stress for Lab Research

- What are the core advantages of smart wearable plantar pressure monitoring systems? Unleash Real-World Gait Analysis

- Why are pressure insoles with FSR used for outdoor gait monitoring? Unleash Real-World Kinetic Analysis