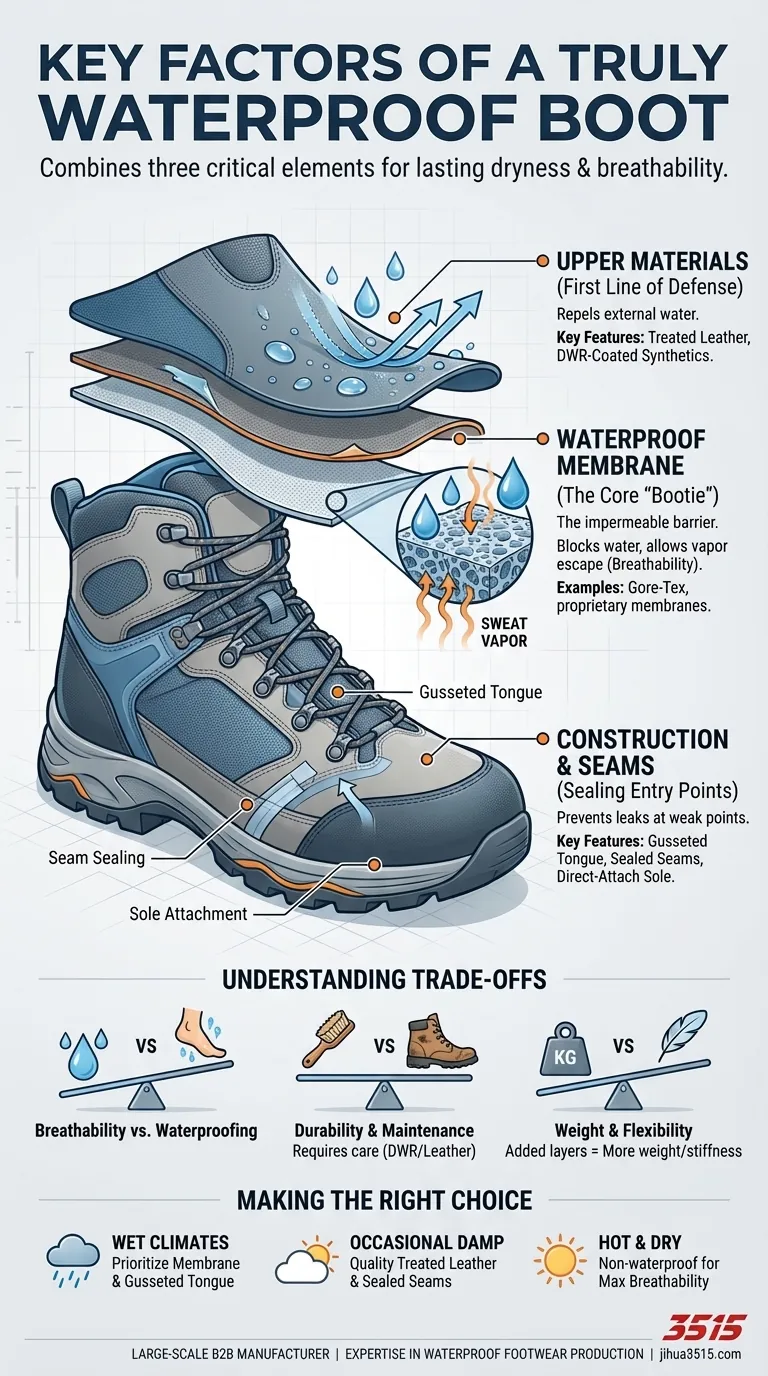

In short, a truly waterproof boot combines three critical elements: a waterproof inner membrane, water-resistant upper materials, and a construction method that seals potential entry points for moisture. It's this combination, rather than any single feature, that ensures your feet stay dry from both external water and internal sweat.

The most crucial element is the internal waterproof membrane, often called a "bootie." While materials and construction provide water resistance, the membrane is the final, impermeable barrier that delivers true waterproofing while still allowing your foot to breathe.

Deconstructing the Waterproof Boot

A common misconception is that a leather boot is inherently waterproof. While high-quality leather offers excellent water resistance, achieving true, lasting waterproofness requires a systematic approach that addresses every potential point of failure, from the sole to the laces.

The Foundation: The Waterproof Membrane

The heart of any modern waterproof boot is an internal membrane, a specialized layer engineered to block water while allowing vapor (sweat) to escape.

How It Works

This membrane is a thin liner, often shaped like a sock or "bootie," that sits between the boot's outer material and the inner lining. It contains billions of microscopic pores—small enough to block larger water droplets from rain or puddles, but large enough to let smaller water vapor molecules from sweat pass through.

Key Materials

The most well-known brand is Gore-Tex, but many manufacturers have proprietary membranes that function on the same principle. This layer is often protected by a fabric like tricot to prevent abrasion from the inside or outside.

The First Line of Defense: Upper Materials

The outer part of the boot, known as the "upper," is your first barrier against the elements. Its job is to repel as much water as possible before it ever reaches the inner membrane.

Treated Leather

Leathers like oil-tanned leather are infused with oils and waxes during the tanning process. This naturally repels water and prevents the leather from becoming saturated and heavy.

Synthetic Fabrics

Modern synthetic materials like nylon are often treated with a Durable Water Repellent (DWR) coating. This causes water to bead up and roll off the surface instead of soaking in.

The Weakest Link: Construction and Seams

A boot is only as waterproof as its weakest point. Water will always find the path of least resistance, which is typically through seams and openings.

Gusseted Tongue

A gusseted tongue is a critical feature where the tongue is attached to the upper along its sides. This creates a continuous, folded barrier that prevents water, dirt, and debris from entering through the lace area.

Seam Sealing

Even the smallest needle holes from stitching can allow water to seep in. In waterproof boots, these seams are sealed from the inside with waterproof tape or sealant to close these microscopic entry points.

Sole Attachment

The method used to attach the sole to the upper is crucial. Direct-attached or cemented soles can create a seamless, waterproof bond. Sewn methods, like a Stitchdown construction, must use waterproof stitching and sealants to maintain their integrity.

Understanding the Trade-offs

Choosing a waterproof boot involves balancing protection with other performance factors. Understanding these compromises is key to selecting the right boot for your needs.

Breathability vs. Waterproofing

There is an inherent trade-off between keeping water out and letting sweat escape. While modern membranes are remarkably good, a fully waterproof boot will always be less breathable than a non-waterproof counterpart. In very hot, dry conditions, a waterproof boot can lead to sweaty, uncomfortable feet.

Durability and Maintenance

DWR coatings on synthetic uppers wear off over time and need to be reapplied. The oils in treated leather need to be replenished to maintain water resistance. The internal membrane can also be damaged by punctures, compromising the entire system.

Weight and Flexibility

The extra layers required for waterproofing—the membrane, sealants, and often more robust materials—add weight and can reduce the overall flexibility of the boot compared to a simpler, non-waterproof design.

Making the Right Choice for Your Goal

Selecting the right boot depends entirely on the conditions you expect to face.

- If your primary focus is hiking in wet, unpredictable climates: Prioritize a boot with a proven waterproof membrane like Gore-Tex and a gusseted tongue.

- If your primary focus is casual wear or work in occasionally damp conditions: A boot made from high-quality, oil-tanned leather with a well-sealed sole construction may be sufficient.

- If your primary focus is activity in hot, dry environments: A non-waterproof boot will offer superior breathability and comfort, even if it means avoiding the occasional puddle.

Ultimately, understanding how these components work together empowers you to look beyond marketing claims and choose a boot truly suited for your environment.

Summary Table:

| Key Factor | Function | Key Features |

|---|---|---|

| Waterproof Membrane | Final barrier blocking water, allowing vapor to escape | Gore-Tex, proprietary "bootie" liners |

| Upper Materials | First line of defense, repelling water | Oil-tanned leather, DWR-coated synthetics |

| Construction & Seams | Seals potential entry points for moisture | Gusseted tongue, sealed seams, waterproof sole attachment |

Need a reliable source for high-performance waterproof boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of waterproof footwear for distributors, brand owners, and bulk clients. Our expertise ensures every pair combines a durable waterproof membrane, high-quality upper materials, and precision construction for guaranteed protection.

Contact us today to discuss your waterproof boot requirements and benefit from our full-scale production capabilities.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

People Also Ask

- What types of ankle fractures were included in the study? A Guide to Common Surgical Cases

- Why is the assessment of chemical usage records essential for footwear? Unlocking Eco-Friendly Production Secrets

- Why is high-precision EEG used in footwear design? Measuring Ergonomic Comfort via Neural Data

- Why is pre-treatment in a constant temperature and humidity environment necessary? Ensuring Reflective Tape Accuracy

- Why is it necessary to configure professional footwear for virtual pedestrian testing? Ensure Biomechanical Accuracy

- What is the significance of using MaxPG in fall risk assessment? Enhance Stability Analysis with Biomechanical Insight

- What materials are used for lasts in vulcanized footwear production and why? The Critical Role of Aluminum

- What is the instep of a cowboy boot? The Key to a Secure, Comfortable Fit