In construction, toe protection safety boots are a non-negotiable line of defense against severe, career-ending injuries. Their core function is to shield the highly vulnerable bones of the foot from the constant threat of falling objects and crushing forces common to every job site. This is accomplished through a reinforced toe cap designed to withstand significant impact and compression.

The importance of a safety boot goes far beyond a simple steel toe cap. It is a comprehensive protective system engineered to counter the multiple, overlapping hazards of a construction environment, from impact and puncture to slips and electrical shock.

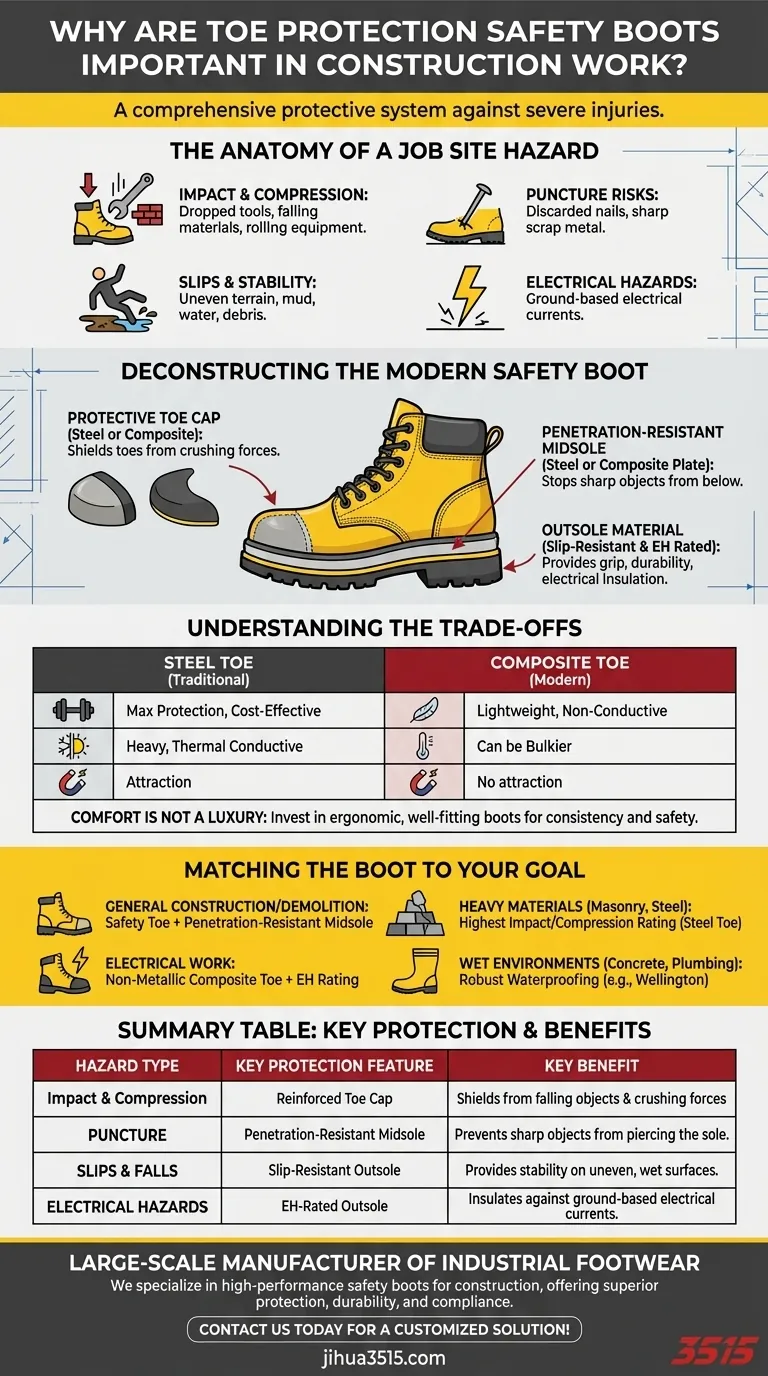

The Anatomy of a Job Site Hazard

To understand the boot, you must first understand the environment. A construction site is a dynamic space where the risks to your feet are constant and varied.

The Primary Threat: Impact and Compression

The most obvious danger comes from above. Dropped tools, falling materials like bricks or lumber, and rolling equipment all pose a direct threat to your feet.

A reinforced toe cap is designed to absorb and deflect the energy from these events, preventing the small, delicate bones in your toes from being crushed. This is the foundational principle of all safety footwear.

Beyond the Obvious: Puncture Risks

Hazards aren't just from above; they are also underfoot. Discarded nails, sharp scrap metal, and upturned rebar can easily pierce the sole of a standard shoe.

For this reason, many construction-grade boots include a penetration-resistant midsole. This is a flexible but durable plate, often made of steel or a composite material, that sits within the sole to stop sharp objects from reaching your foot.

The Constant Dangers: Slips and Stability

Construction sites are rarely flat or clean. Uneven terrain, mud, water, and debris create a high risk for slips, trips, and falls, which are among the most common causes of injury.

Modern safety boots feature high-traction, slip-resistant outsoles with specialized tread patterns. They provide the stability needed to navigate challenging surfaces safely.

Deconstructing the Modern Safety Boot

While "steel toe" is the common term, the technology inside a safety boot is more nuanced. Understanding the key components allows you to select the right tool for the job.

The Protective Toe Cap

This is the primary shield for your toes. The two main types are steel and composite. Both must meet the same stringent safety standards for impact and compression resistance.

The Midsole Plate

As mentioned, this component is critical for preventing puncture injuries from below. It is a feature no general construction worker should overlook.

The Outsole Material

The outsole determines the boot's grip and durability. Materials are chosen for their resistance to oil, chemicals, heat, and abrasion while providing maximum traction. Some are also rated for Electrical Hazard (EH) protection, insulating you from ground-based electrical currents.

Understanding the Trade-offs

Choosing the right toe protection involves balancing features, materials, and the specific demands of your work.

Steel Toe: The Traditional Standard

Steel caps offer maximum protection and are often the most cost-effective option. Their primary drawbacks are weight and thermal conductivity—they can get very cold in winter and hot in the summer.

Composite Toe: The Modern Alternative

Composite toe caps are made from materials like Kevlar, carbon fiber, or plastic. They are significantly lighter than steel, do not conduct electricity or temperature, and won't set off metal detectors. However, they can sometimes be bulkier than steel to provide the same level of protection.

Comfort is Not a Luxury

An uncomfortable boot is a boot that doesn't get worn properly, defeating its purpose. Modern safety footwear has made huge strides in ergonomics, cushioning, and fit. Investing in a well-fitting, comfortable boot is an investment in your own consistency and safety.

Matching the Boot to Your Goal

Selecting the correct boot is a critical professional decision. Use your primary job function as your guide.

- If your primary focus is general construction or demolition: A boot with both a safety toe and a penetration-resistant midsole is essential.

- If your primary focus is working with heavy materials (masonry, steel erection): Prioritize the highest impact and compression rating; a steel toe is a reliable and proven choice here.

- If your primary focus involves electrical work: A non-metallic composite toe boot with an explicit Electrical Hazard (EH) rating is non-negotiable.

- If your primary focus is in consistently wet environments (concrete, plumbing): Look for robust waterproofing, potentially in a safety Wellington style, to ensure both protection and foot health.

Ultimately, the right safety boot is not just a piece of required equipment; it is a fundamental tool that enables you to perform your job with confidence and security.

Summary Table:

| Hazard Type | Key Protection Feature | Key Benefit |

|---|---|---|

| Impact & Compression | Reinforced Toe Cap (Steel/Composite) | Shields toes from falling objects & crushing forces |

| Puncture | Penetration-Resistant Midsole | Prevents sharp objects from piercing the sole |

| Slips & Falls | Slip-Resistant Outsole | Provides stability on uneven, wet, or oily surfaces |

| Electrical Hazards | EH-Rated Outsole | Insulates against ground-based electrical currents |

As a large-scale manufacturer, 3515 produces a comprehensive range of industrial footwear for distributors, brand owners, and bulk clients. We specialize in high-performance safety boots tailored for construction, offering superior toe protection, puncture resistance, and slip resistance. Our production capabilities cover all types of safety shoes and boots, ensuring durability and compliance with industry standards. Protect your workforce with reliable, comfortable safety footwear—contact us today to discuss your needs and receive a customized solution!

Visual Guide

Related Products

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- High Performance Fire-Retardant Waterproof Safety Boots

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Premium KPU Injection Athletic Style Safety Shoes

People Also Ask

- How do women's safety toe work boots protect against foot injuries? A Complete Guide to Workplace Foot Safety

- What safety features can some gumboots have? Essential PPE for Hazardous Work Environments

- In what work situations might cowboy boots not be appropriate? A Guide to Safety & Dress Code Compliance

- What are steel toe boots and how are they designed? Essential Guide to Industrial Footwear Safety

- What is the overall recommendation regarding steel toe boot usage? Essential for Maximum Protection