In an oilfield, slip-resistant soles are your most critical defense against the constant threat of slips and falls. These environments are inherently hazardous, with surfaces frequently contaminated by oil, drilling mud, chemicals, and water. A properly engineered slip-resistant sole provides the essential traction needed to maintain stability and prevent potentially catastrophic injuries in these unpredictable conditions.

The core purpose of a slip-resistant sole is not just to provide grip, but to ensure reliable footing on surfaces where traction is compromised. It transforms a simple boot into a critical piece of safety equipment, mitigating the single most common cause of workplace injury.

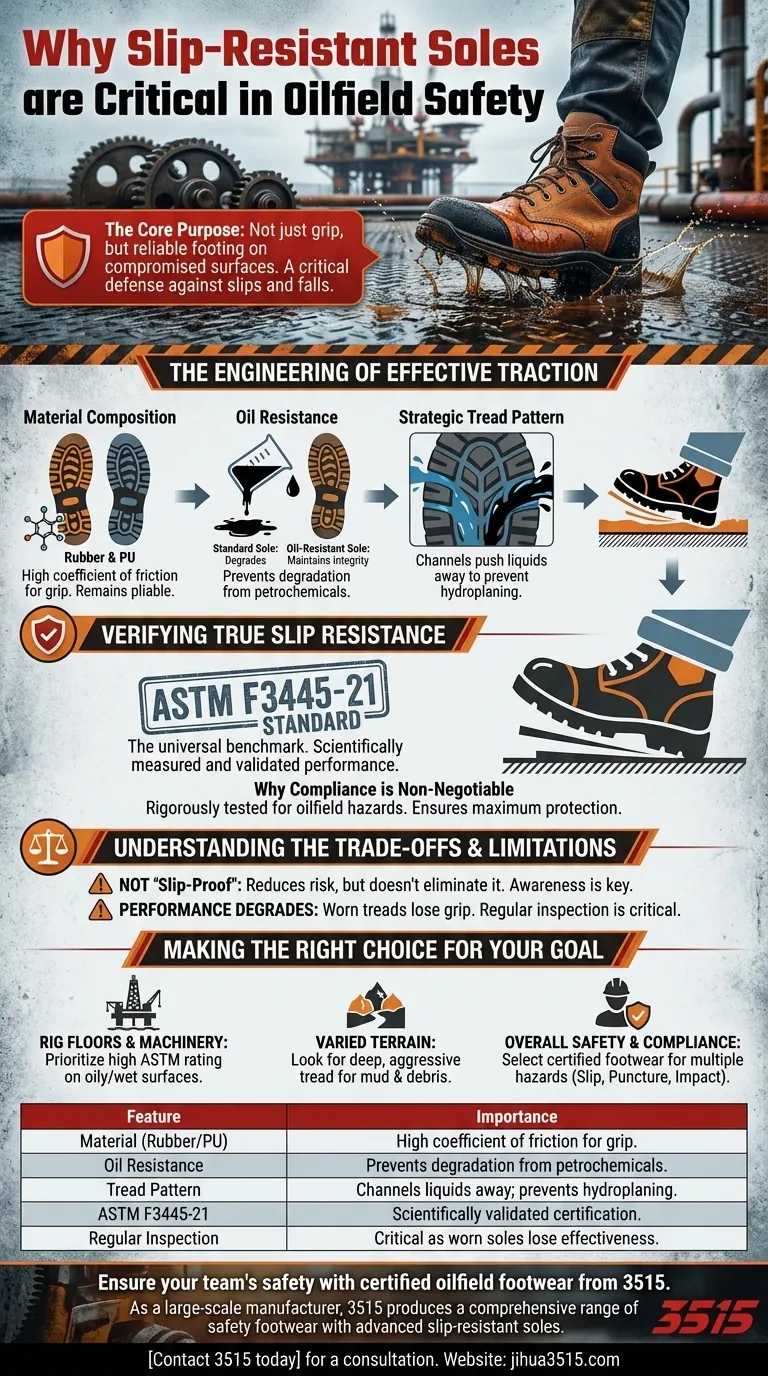

The Engineering of Effective Traction

A truly effective slip-resistant sole is a result of deliberate material science and design, not just a label on a box. Several key factors work together to provide reliable grip.

Material Composition Matters

The materials used are the foundation of slip resistance. Soles are typically made from durable rubber or polyurethane (PU).

These compounds are chosen for their high coefficient of friction, which is the scientific measure of how much grip a material has. They are engineered to remain pliable and effective across a range of temperatures.

The Importance of Oil Resistance

Standard rubber can degrade, swell, or harden when exposed to petrochemicals, which drastically reduces its gripping ability.

Oil-resistant soles are made from specialized compounds that maintain their structural integrity and traction even with prolonged contact with oil and other substances common in the oilfield.

Strategic Tread Pattern Design

The pattern on the bottom of the sole is just as important as the material. An effective tread features small, sharp-angled channels.

These channels are designed to push liquids like oil and water away from the point of contact between the sole and the surface, allowing the sole to make a firm connection and prevent hydroplaning.

Verifying True Slip Resistance

The term "slip-resistant" can be used loosely in marketing. True safety relies on adherence to objective, verifiable industry standards.

The ASTM F3445-21 Standard

This is the universal standard specification for slip resistance in safety footwear. It provides a definitive benchmark for testing.

When a boot is certified to this ASTM standard, it means its slip resistance has been scientifically measured and validated, giving employers and workers confidence in its performance.

Why Compliance is Non-Negotiable

Adherence to established safety standards ensures that the footwear has been rigorously tested for the specific hazards of an oilfield.

Choosing compliant footwear is the most reliable way for safety managers to ensure they are providing maximum protection and meeting regulatory requirements.

Understanding the Trade-offs

Even the best technology has limitations. Understanding them is key to maximizing your safety.

No Sole is "Slip-Proof"

Slip-resistant soles dramatically reduce the risk of a fall, but they cannot eliminate it entirely. Worker awareness and caution remain essential.

Performance Degrades with Wear

As a sole wears down, the tread pattern becomes less defined and the material loses some of its gripping texture. This diminishes its slip-resistant capabilities.

Regularly inspecting your boots for significant wear is a critical safety habit. A worn-out sole is a safety hazard.

Context is Everything

A sole designed for flat, oily concrete may perform differently in deep mud or on icy metal grating. The specific environment dictates which tread design and material compound will be most effective.

Making the Right Choice for Your Goal

Selecting the right footwear requires matching the sole's features to your specific work environment and tasks.

- If your primary focus is working on rig floors or around machinery: Prioritize soles with a high ASTM slip-resistance rating specifically tested on oily and wet surfaces.

- If your primary focus is traversing varied and uneven terrain: Look for a sole with a deep, aggressive tread pattern for mud and debris, in addition to its certified slip-resistant properties.

- If your primary focus is overall safety and compliance: Always select footwear that is certified for multiple hazards, including slip resistance (ASTM F3445-21), puncture resistance, and impact protection.

Investing in footwear with the correct, certified slip-resistant sole is a foundational step in managing your personal safety in a demanding environment.

Summary Table:

| Feature | Importance for Oilfield Safety |

|---|---|

| Material (Rubber/PU) | Provides high coefficient of friction for grip. |

| Oil Resistance | Prevents degradation and maintains traction with petrochemicals. |

| Tread Pattern | Channels liquids away to prevent hydroplaning. |

| ASTM F3445-21 Standard | Scientifically validated certification for slip resistance. |

| Regular Inspection | Critical as worn soles lose effectiveness. |

Ensure your team's safety with certified oilfield footwear from 3515.

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of certified safety shoes and boots, engineered with the advanced slip-resistant soles detailed in this article.

We provide the reliable, compliant footwear necessary to protect your workforce in hazardous environments. Let us help you mitigate risks and meet safety standards.

Contact 3515 today for a consultation on your safety footwear needs.

Visual Guide

Related Products

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

- Premium Sport Style Safety Boots for Bulk Orders

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

People Also Ask

- Are safety toe options available for women's work boots? A Guide to Steel, Composite & Alloy Toes

- How do safety shoes protect you? A Guide to Essential Footwear Safety Features

- Are safety shoes worth it? The Critical Investment in Workplace Safety & Foot Health

- What distinguishes heavy duty work boots from regular boots? Safety, Durability & Purpose Explained

- What is a working boot? Your Essential Guide to Foot Safety and Durability