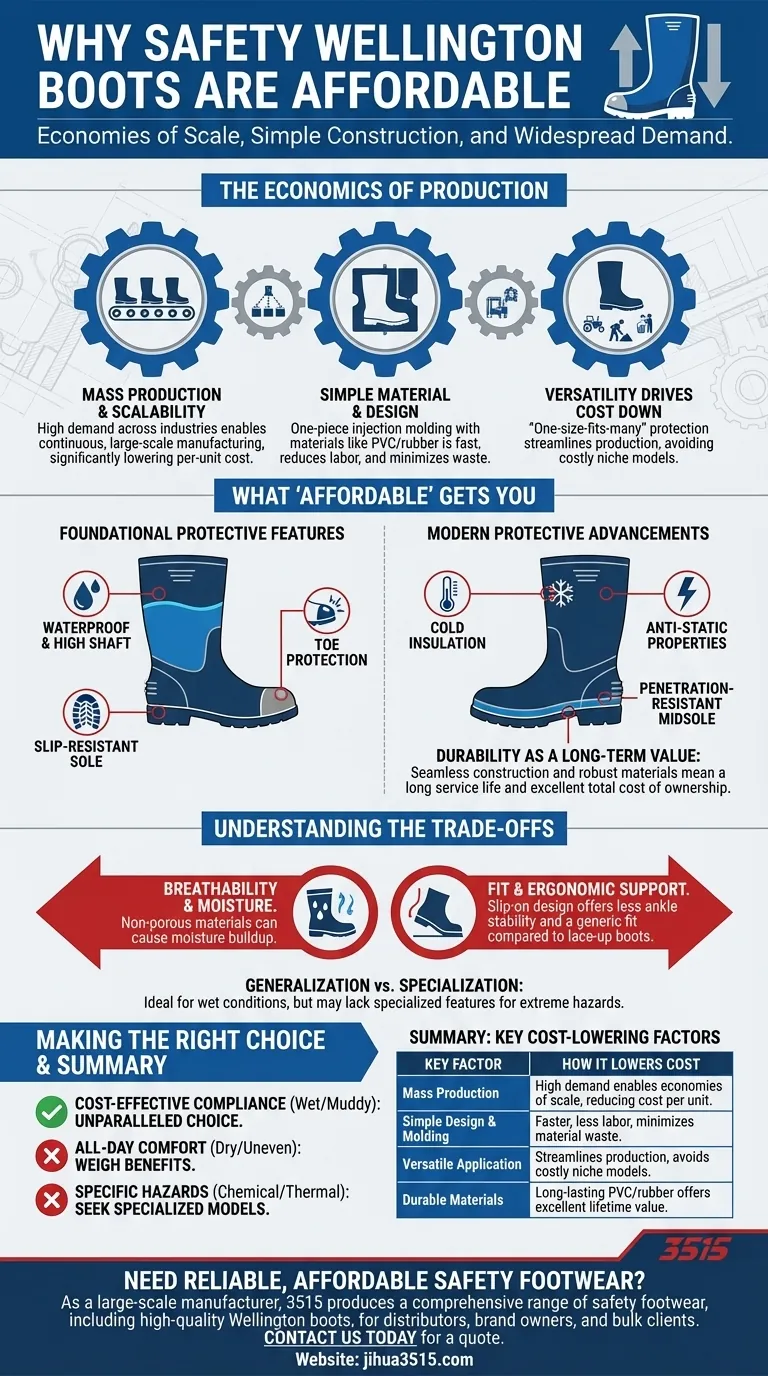

To put it simply, safety Wellington boots are affordable primarily due to mass production and material efficiency. Their widespread use across numerous industries creates enormous demand, allowing manufacturers to leverage economies of scale, while their simple, molded construction from materials like PVC or rubber is inherently more cost-effective than crafting complex, multi-panel leather boots.

The affordability of safety Wellingtons is not a sign of low quality, but a direct result of a highly efficient manufacturing process and a design that perfectly meets the most common industrial hazards—wetness, slips, and impacts—without the cost of over-engineering.

The Economics of Wellington Boot Production

The price of any piece of equipment is a reflection of its design, materials, and manufacturing scale. For safety Wellingtons, all three factors align to create a remarkably cost-effective solution.

Mass Production and Economies of Scale

Because Wellington boots are a standard requirement in agriculture, construction, food processing, and sanitation, the global demand is massive and consistent. This allows for continuous, high-volume production runs that significantly lower the cost per unit.

Simplicity in Material and Design

Unlike traditional safety boots that require cutting and stitching multiple pieces of leather or fabric, most Wellingtons are made using an injection molding process. This method, which forms the entire boot from PVC or rubber in a single piece, is incredibly fast, reduces labor costs, and minimizes material waste.

Versatility as a Cost Driver

The fundamental design provides a baseline of protection—waterproofing, impact resistance, and slip resistance—that is valuable across countless job sites. This "one-size-fits-many" functionality means manufacturers don't need to create dozens of niche models, streamlining their production lines and further reducing costs.

What "Affordable" Actually Gets You

An affordable price does not mean you are sacrificing core safety. In fact, the inherent design of a Wellington boot provides excellent protection against some of the most frequent workplace hazards.

Foundational Protective Features

Every standard safety Wellington offers a non-negotiable trio of protections. The waterproof material and high shaft design keep workers dry and clean in wet or muddy conditions. The slip-resistant sole provides critical traction, while the built-in toe protection guards against impacts.

Modern Protective Advancements

The modern Wellington is far more than a simple rubber boot. Many affordable models now include advanced features tailored to specific risks, such as cold insulation for low-temperature work, anti-static properties for sensitive environments, and penetration-resistant midsoles to protect against sharp objects.

Durability as a Long-Term Value

The seamless, molded construction eliminates weak points like stitching that can fail over time. The robust materials are resistant to chemicals, oils, and abrasion, giving the boots a long service life and making them an even more economical choice when measured by total cost of ownership.

Understanding the Trade-offs

While their value is undeniable, it's important to understand the inherent trade-offs in the Wellington design to ensure they are the right choice for your specific environment.

Breathability and Moisture Management

The very feature that makes Wellingtons waterproof—their non-porous material—also makes them non-breathable. During long shifts or in warm climates, this can lead to sweat and moisture buildup inside the boot, which can cause discomfort.

Fit and Ergonomic Support

A lace-up boot can be tightened to provide firm ankle support and a custom fit. The slip-on design of a Wellington offers less ankle stability and a more generic fit, which may not be ideal for workers covering long distances on highly uneven terrain.

Generalization vs. Specialization

Safety Wellingtons are masters of general-purpose protection, especially in wet conditions. However, for highly specialized tasks requiring features like extreme cut resistance or metatarsal guards found in more complex and expensive footwear, a Wellington may not be the optimal tool.

Making the Right Choice for Your Needs

Choosing the right footwear means matching the boot's strengths to your primary operational challenges.

- If your primary focus is cost-effective compliance in wet, muddy, or sanitary environments: The safety Wellington is an unparalleled choice for its protective value and low cost.

- If your primary focus is all-day comfort during long shifts on dry, uneven ground: You should weigh the Wellington's benefits against a potentially more breathable and supportive lace-up safety boot.

- If your primary focus is protection against a broad range of chemical or thermal hazards: Seek out modern Wellington models that are specifically rated for the substances or temperatures present in your workplace.

Ultimately, selecting the correct safety footwear is about understanding that the most effective tool is the one designed for the job at hand.

Summary Table:

| Key Factor | How It Lowers Cost |

|---|---|

| Mass Production | High, consistent demand enables economies of scale, reducing the cost per unit. |

| Simple Design & Molding | One-piece injection molding is faster, uses less labor, and minimizes material waste. |

| Versatile Application | A "one-size-fits-many" approach streamlines production, avoiding costly niche models. |

| Durable Materials | Long-lasting PVC/rubber construction offers excellent value over the boot's lifetime. |

Need reliable, affordable safety footwear for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear, including high-quality Wellington boots, for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, ensuring you get the perfect combination of protection, comfort, and value.

Contact us today for a quote and discover how we can meet your specific safety and budgetary requirements.

Visual Guide

Related Products

- Customizable Slip-On Safety Shoes Direct from the Factory for Wholesale

- Wholesale Customizable Suede Safety Boots - Puncture-Proof with Velcro Closure

- Durable Mid-Cut Tactical Boots for Wholesale & Private Label

- Durable Leather Work Boots for Wholesale & Custom OEM Manufacturing

- Durable Military Combat Boots with Water Drainage for Wholesale & OEM

People Also Ask

- Why is proper fit important in work boots? Ensure Safety, Comfort & Long-Term Health

- What organization sets national standards for workplace safety in the U.S.? OSHA's Role Explained

- What is ASTM International and what does it do? A Guide to Global Standards

- What are the four key aspects to consider when choosing high-quality safety footwear? Ensure True Anatomical Fit & Protection

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management