Safety boots are a non-negotiable component of personal protective equipment (PPE) in construction and manufacturing because they are engineered to prevent severe, career-ending injuries. They provide a critical line of defense against the most common and dangerous physical hazards found in these environments, including impact from falling objects, compression from heavy machinery, punctures from sharp debris, and slips on hazardous surfaces.

The core purpose of a safety boot is not simply to cover the foot, but to act as a specialized safety system. Each feature—from the reinforced toe cap to the non-slip sole—is a direct countermeasure to a specific, high-risk workplace hazard.

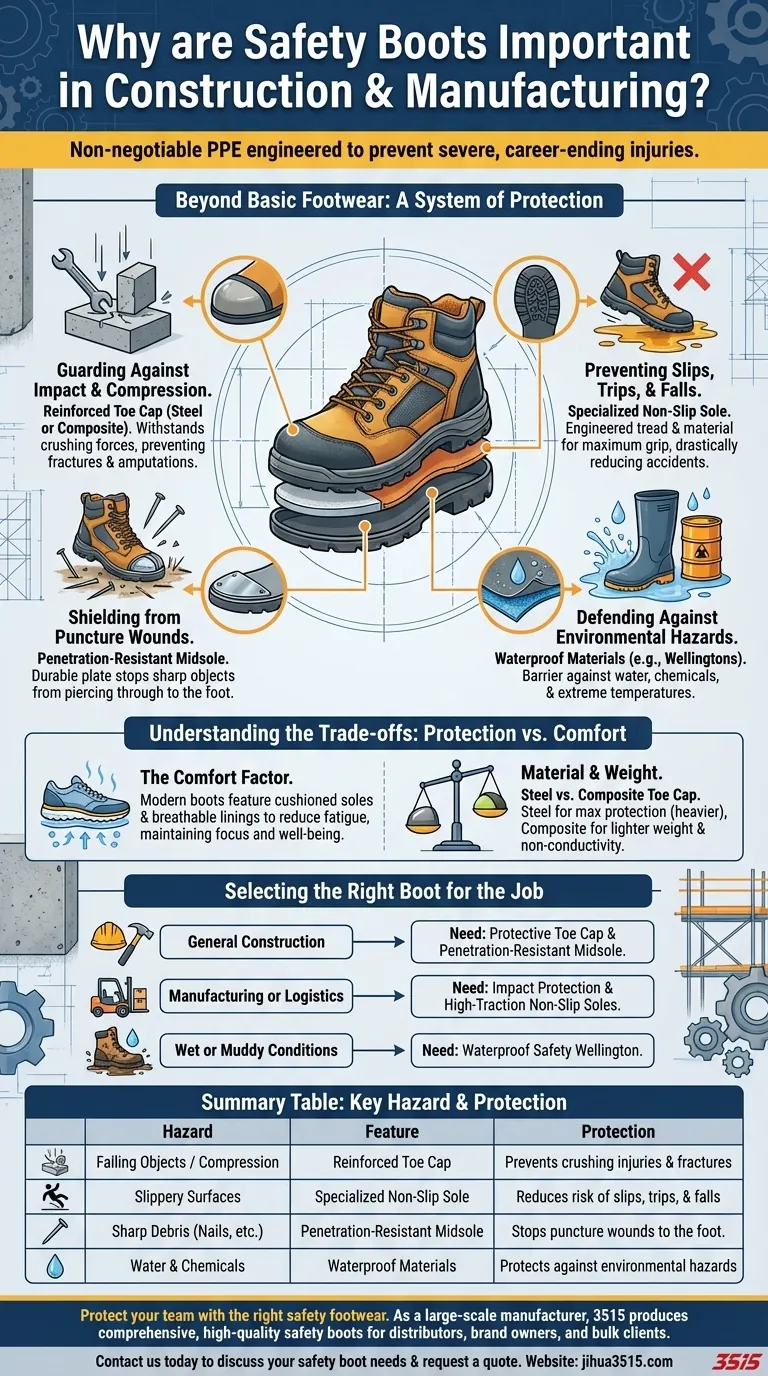

Beyond Basic Footwear: A System of Protection

Thinking of a safety boot as just a "strong shoe" misses the point. It's a piece of engineered equipment where different components work together to provide comprehensive protection against a range of predictable workplace dangers.

Guarding Against Impact and Compression

In construction and manufacturing, the feet are constantly exposed to falling tools, materials, and heavy equipment. The toes are particularly vulnerable to crushing injuries.

To counter this, safety boots feature a protective toe cap, typically made of steel or a lighter composite material. This reinforcement is designed to withstand significant impact and compression forces, preventing severe fractures and amputations.

Preventing Slips, Trips, and Falls

Workplace surfaces in these industries are often uneven, wet, or oily, making slips and falls a leading cause of injury.

Safety boots are designed with specialized non-slip soles. The material and tread pattern are engineered to provide maximum grip and stability, drastically reducing the risk of accidents that can lead to sprains, fractures, or more serious harm.

Shielding from Puncture Wounds

Construction sites are littered with sharp objects like nails, screws, and rebar scraps. Stepping on one of these can cause a deep, debilitating puncture wound.

Many safety boots include a penetration-resistant midsole. This is a flexible but durable plate, often made of steel or composite fabric, that runs along the sole to stop sharp objects from piercing through to the foot.

Defending Against Environmental Hazards

Beyond physical impacts, workers often face environmental risks like water, chemicals, or extreme temperatures.

Boots like safety Wellingtons are made from waterproof materials to protect against water exposure and maintain hygiene. The durable outer materials, such as leather or advanced synthetic textiles, also provide a barrier against splashes and other elements.

Understanding the Trade-offs: Protection vs. Comfort

While protection is the primary goal, a boot that causes pain or fatigue can become a safety hazard itself by distracting the worker. Manufacturers understand this critical balance.

The Comfort Factor

Modern safety boots are not the rigid, unforgiving footwear of the past. They often include features like cushioned soles and breathable linings to reduce fatigue.

Wearing comfortable footwear for long shifts helps maintain focus and physical well-being, which is essential for staying alert and safe on the job.

Material and Weight

The choice between a steel toe cap and a composite toe cap is a common consideration. Steel offers maximum protection but adds weight, while composite materials are lighter and don't conduct electricity but may offer slightly different impact ratings.

The right choice depends on balancing the specific hazards of the job with the need for mobility and all-day comfort.

Selecting the Right Boot for the Job

Choosing the correct safety boot requires matching its features to the specific risks of your work environment.

- If your primary focus is general construction: You need a boot with both a protective toe cap and a penetration-resistant midsole to guard against falling objects and sharp debris.

- If your primary focus is manufacturing or logistics: Prioritize a boot with excellent impact protection and high-traction, non-slip soles to handle heavy materials and smooth concrete floors.

- If your primary focus is working in wet or muddy conditions: A waterproof safety Wellington is essential for protection from water, hygiene, and impact hazards.

Ultimately, wearing the right safety boot is one of the most direct and effective actions you can take to ensure your personal safety on the job.

Summary Table:

| Key Hazard | Safety Boot Feature | Protection Provided |

|---|---|---|

| Falling Objects / Compression | Reinforced Toe Cap (Steel/Composite) | Prevents crushing injuries and fractures |

| Slippery Surfaces | Specialized Non-Slip Sole | Reduces risk of slips, trips, and falls |

| Sharp Debris (Nails, etc.) | Penetration-Resistant Midsole | Stops puncture wounds to the foot |

| Water & Chemicals | Waterproof Materials (e.g., Wellingtons) | Protects against environmental hazards |

Protect your team with the right safety footwear. As a large-scale manufacturer, 3515 produces a comprehensive range of high-quality safety boots for distributors, brand owners, and bulk clients. Our production capabilities ensure durable, comfortable, and compliant footwear tailored to the specific hazards of construction and manufacturing. Contact us today to discuss your safety boot needs and request a quote.

Visual Guide

Related Products

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium Grain Leather Safety Boots for Bulk Supply

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Wholesale Durable Safety Boots Manufacturer Customizable Steel Toe Work Boots

People Also Ask

- Is it true that steel toe boots make your toes colder? The Truth About Cold-Weather Work Boots

- What additional safety features do steel toe work boots often include? Beyond the Steel Toe Cap

- Do steel toe boots increase the risk of trips and falls? How Quality Design Enhances Stability

- In what work situations might cowboy boots not be appropriate? A Guide to Safety & Dress Code Compliance

- What is the overall recommendation regarding steel toe boot usage? Essential for Maximum Protection