At its core, the higher manufacturing cost of a Goodyear welted shoe is a direct result of two factors: a more complex, labor-intensive construction process and the use of higher-quality, durable materials. Unlike mass-produced shoes with soles simply glued on by automated machinery, Goodyear welting requires skilled craftsmanship and numerous detailed steps to create a shoe that is built to be repaired, not replaced.

The premium price of a Goodyear welted shoe is not for the initial product alone, but for its entire lifecycle. You are investing in a system of construction that prioritizes durability and repairability, offering significantly better long-term value and sustainability than disposable footwear.

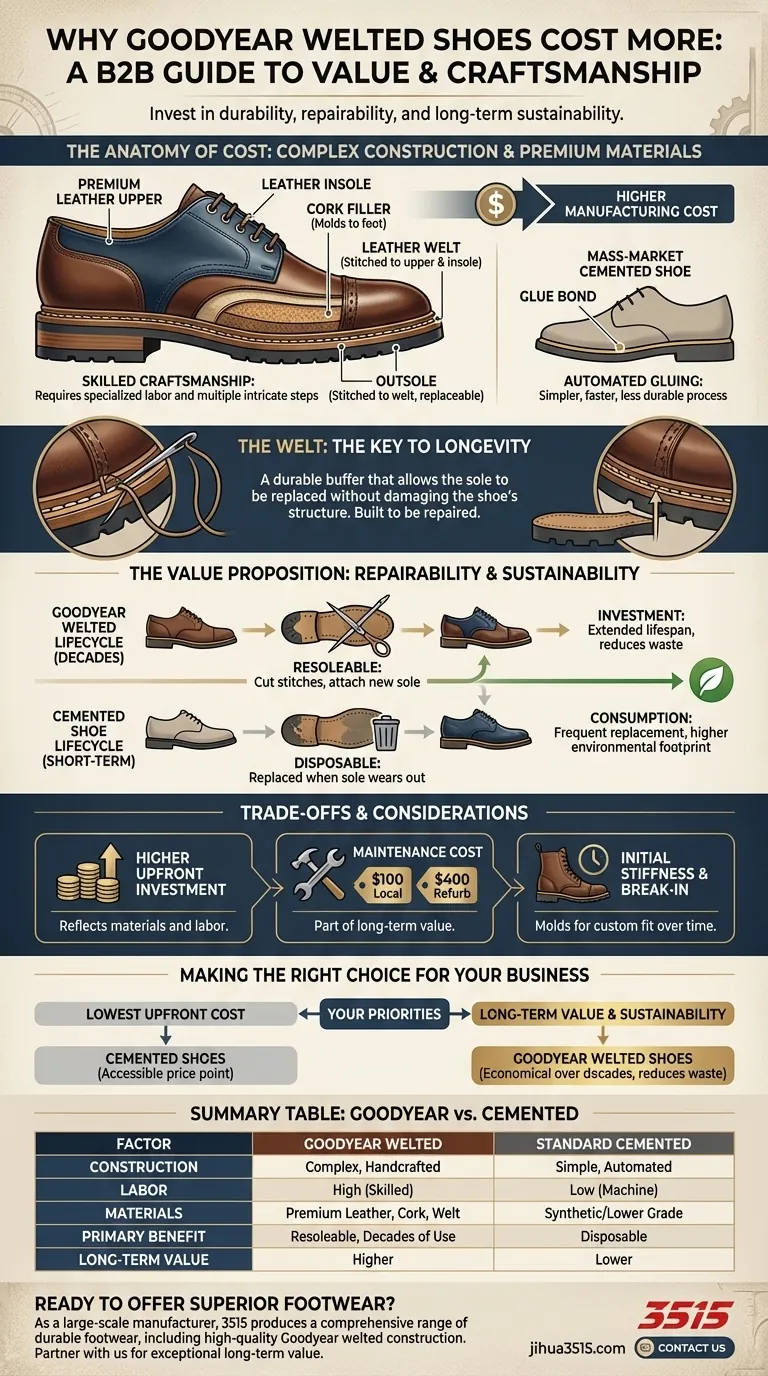

The Anatomy of the Cost: Labor and Materials

To understand the price, you have to understand the process. The cost is embedded in the very structure of the shoe, which is fundamentally different from that of a typical mass-market product.

The Labor-Intensive Construction

The Goodyear welting process is inherently more complicated and time-consuming. It cannot be fully automated in the same way as cementing a sole to an upper.

This process involves more steps and requires skilled artisans to operate machinery and perform finishing work by hand, which increases labor costs significantly.

The Role of the Welt

The key component is the welt, a strip of leather that runs along the perimeter of the outsole. This welt is stitched to the shoe's upper and insole.

The outsole is then stitched directly to the welt, not to the upper. This creates a durable, water-resistant buffer and, most importantly, allows the sole to be removed and replaced without damaging the rest of the shoe.

Meticulous Finishing Steps

Beyond the primary construction, the finishing process for a quality welted shoe is also incredibly detailed.

Steps like using hot irons to smooth the sole edges, nailing leather heels into place, and applying multiple layers of cleaning, polishing, and waxing are all done with precision. Each of these manual stages adds to the final manufacturing cost.

The Value Proposition: Repairability and Longevity

The higher manufacturing cost is not just about producing a shoe; it's about producing a long-term, serviceable product. The initial price reflects its potential for an extended lifespan.

Built for a Second Life (and Third)

The primary benefit of the Goodyear welt is its repairability. When the sole wears out, a cobbler can simply cut the stitches holding it to the welt and attach a new one.

This process can be repeated multiple times, allowing a single pair of shoes to last for decades with proper care. This stands in stark contrast to cemented shoes, which are often discarded once the sole wears down.

A More Sustainable Choice

This ability to resole makes Goodyear welted footwear a more sustainable option. By extending the life of the shoe, you drastically reduce waste and the need to purchase frequent replacements.

Understanding the Trade-offs

While the benefits are significant, it's crucial to acknowledge the practical considerations that come with this construction method.

The Higher Upfront Investment

The most obvious trade-off is the initial price. The materials and labor involved mean these shoes will always cost more than their mass-produced counterparts.

The Cost of Maintenance

While resoling extends the shoe's life, it is not free. A local cobbler might charge around $100, while sending the shoes back to the original manufacturer for a full refurbishment can cost up to $400.

This maintenance cost is part of the long-term investment in the footwear.

Initial Stiffness and Break-In

The robust construction of a Goodyear welted shoe often results in a stiffer feel out of the box. They typically require a break-in period for the leather insole and cork filling to mold to your foot, which is a consideration for immediate comfort.

Making the Right Choice for Your Goal

Deciding whether to invest in Goodyear welted footwear depends entirely on your priorities.

- If your primary focus is the lowest possible upfront cost: A Goodyear welted shoe is likely not the best choice, as cemented shoes offer a more accessible price point for immediate needs.

- If your primary focus is long-term value and durability: The ability to resole the shoe multiple times makes it a far more economical investment over the course of a decade.

- If your primary focus is sustainability: Choosing a repairable shoe over a disposable one significantly reduces your environmental footprint by minimizing waste.

Ultimately, investing in a Goodyear welted shoe is a commitment to a tradition of quality craftsmanship designed to last a lifetime.

Summary Table:

| Cost Factor | Goodyear Welted Shoes | Standard Cemented Shoes |

|---|---|---|

| Construction | Complex, multi-step, handcrafted process | Simple, automated gluing process |

| Labor | High (skilled artisans) | Low (machine-operated) |

| Materials | Premium leather, cork filler, leather welt | Often synthetic or lower-grade materials |

| Primary Benefit | Can be resoled multiple times for decades of use | Typically disposable once the sole wears out |

| Long-Term Value | Higher (cost per wear decreases over time) | Lower (requires frequent replacement) |

Ready to Offer Your Customers Superior, Long-Lasting Footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including the high-quality, repairable Goodyear welted construction detailed in this article.

Partner with us to provide your customers with footwear that delivers exceptional long-term value and reduces waste.

Contact our team today to discuss your manufacturing needs and how we can help build your brand's reputation for quality.

Visual Guide

Related Products

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Durable & Breathable Training Shoes for Custom Brands

- Premium KPU Athletic Safety Shoes for Wholesale

- Wholesale Training Shoes with Dial Lacing System Custom OEM Manufacturing

People Also Ask

- Does more ground contact area mean better support? Unlock the Secrets of Stable Footwear

- What is a Flyknit shoe? The Ultimate Guide to Seamless, Lightweight Performance

- How do non-slip athletic shoes differ from regular athletic shoes? Discover the Grip Technology

- What is high-tech 'air' mesh, and how is it used in footwear? The Key to Cool, Lightweight Shoes

- What are the characteristics of canvas as a shoe material? A Guide to Lightweight, Breathable Footwear