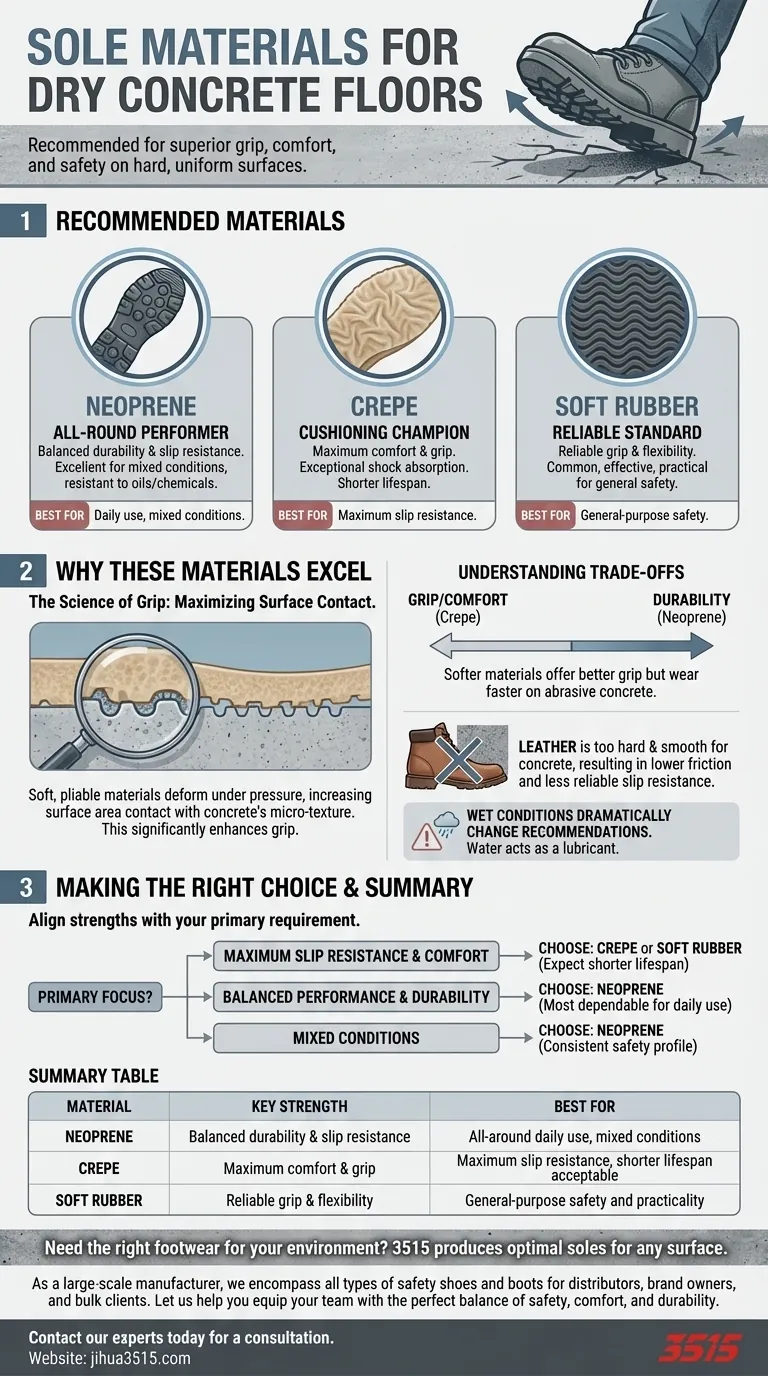

For dry concrete floors, the most recommended sole materials are neoprene, crepe, and soft rubber. These materials are chosen specifically for their ability to provide superior grip, comfort, and safety on this hard, uniform surface.

The optimal sole material for a specific floor is determined by its physical properties. For a hard, abrasive surface like dry concrete, materials that maximize surface contact and provide cushioning are paramount for both safety and long-term comfort.

Why These Materials Excel on Dry Concrete

The effectiveness of a shoe sole on any surface comes down to physics. Concrete, even when it appears smooth, has a micro-texture. The best sole materials conform to this texture to maximize the coefficient of friction, which translates directly to slip resistance.

The Importance of Softness and Grip

Softer, more pliable materials like crepe and soft rubber excel on hard surfaces. They can deform slightly under pressure, increasing the total surface area in contact with the floor.

This increased contact enhances grip significantly, providing a more secure footing with every step.

Neoprene: The All-Round Performer

Neoprene is a type of synthetic rubber known for its excellent balance of properties. It offers very good slip resistance on dry surfaces while also being durable and resistant to degradation from oils or chemicals.

This makes neoprene a highly reliable and versatile choice for work environments with concrete flooring.

Crepe: The Cushioning Champion

Crepe rubber has a unique, porous texture that provides outstanding grip and shock absorption. Its natural softness makes it exceptionally comfortable for walking or standing on hard concrete for extended periods.

However, this softness often comes at the expense of durability compared to denser rubber compounds.

Soft Rubber: The Reliable Standard

Soft rubber compounds are a common and effective choice for general-purpose footwear. They provide a dependable level of grip and flexibility, making them a safe and practical option for dry concrete environments.

Understanding the Trade-offs

Choosing a sole material is rarely about finding a single "best" option, but rather the right balance of features for your specific needs. Understanding the inherent trade-offs is key to making an informed decision.

Durability vs. Maximum Grip

There is often an inverse relationship between a material's softness and its durability.

Materials like crepe offer phenomenal grip but will wear down faster on the abrasive surface of concrete. Denser materials like neoprene may offer slightly less grip but provide a longer service life.

The Absence of Leather

You may notice that leather soles, while recommended for dry tile or wood, are not on the list for concrete.

Leather is a very durable material, but it is also relatively hard and smooth. It cannot conform to concrete's micro-texture as effectively as rubber, resulting in a lower coefficient of friction and less reliable slip resistance on that specific surface.

The Impact of Wet Conditions

The recommendations change dramatically when a surface becomes wet. As seen with wet concrete or tile, the list of suitable materials narrows.

This is because water acts as a lubricant, and only certain materials with specific tread patterns can effectively channel it away to maintain contact with the floor. This highlights why a choice for a "dry" floor may not be safe if conditions can change.

Making the Right Choice for Your Goal

To select the best sole, align the material's strengths with your primary requirement.

- If your primary focus is maximum slip resistance and comfort: Choose crepe or a high-quality soft rubber sole, but be prepared for a shorter lifespan.

- If your primary focus is balanced, all-around performance and durability: Neoprene is the most dependable and long-lasting choice for daily use on concrete.

- If you frequently encounter mixed conditions beyond just dry concrete: A versatile neoprene sole provides the most consistent safety profile across various surfaces.

Understanding how a sole material interacts with the floor empowers you to choose footwear with confidence and precision.

Summary Table:

| Material | Key Strength | Best For |

|---|---|---|

| Neoprene | Balanced durability & slip resistance | All-around daily use, mixed conditions |

| Crepe | Maximum comfort & grip | Maximum slip resistance, shorter lifespan acceptable |

| Soft Rubber | Reliable grip & flexibility | General-purpose safety and practicality |

Need the right footwear for your environment?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear with the optimal soles for any surface. Our production capabilities encompass all types of safety shoes and boots for distributors, brand owners, and bulk clients.

Let us help you equip your team with the perfect balance of safety, comfort, and durability.

Contact our experts today for a consultation

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium KPU Injection Athletic Style Safety Shoes

People Also Ask

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- What materials are used for safety toes? Choose Steel, Composite, or Aluminum for Your Work Boots

- Can heavy duty work boots be worn daily outside of work? Discover Durable, All-Day Comfort

- What are the primary protective functions of composite-toe boots? A Guide to Modern Safety Footwear