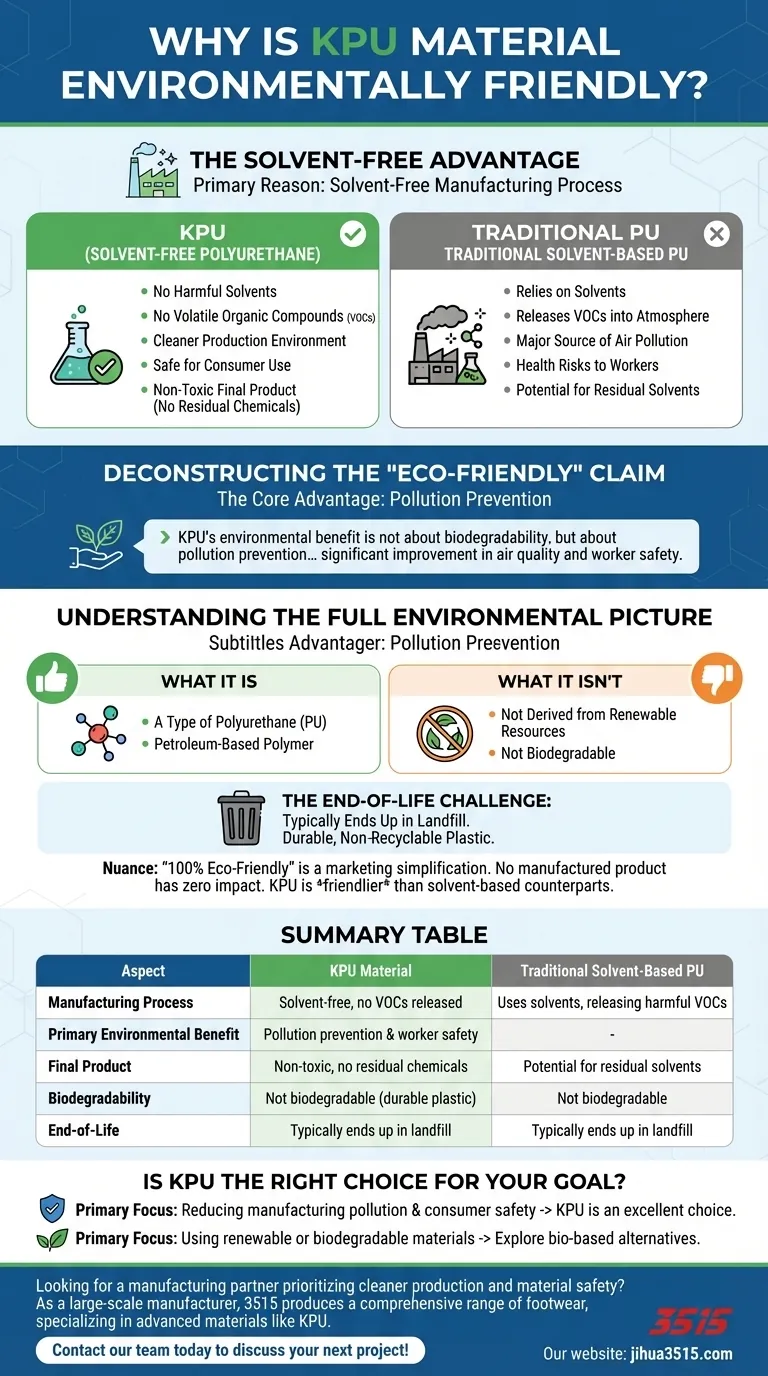

The primary reason KPU material is considered environmentally friendly is its solvent-free manufacturing process. Unlike traditional methods for creating similar materials, the production of KPU avoids the use of volatile organic compounds (VOCs), which are harmful pollutants. This results in a cleaner production environment and a final product that is non-toxic and safe for consumer use.

KPU's environmental benefit is not about biodegradability, but about pollution prevention. By eliminating harmful solvents from its manufacturing process, it offers a significant improvement in air quality and worker safety compared to conventional polyurethane production.

Deconstructing the "Eco-Friendly" Claim

To understand KPU's environmental credentials, we must look specifically at its chemistry and production. The term "eco-friendly" is broad, but for KPU, it centers on a single, critical distinction.

The Core Advantage: Solvent-Free Polyurethane

Traditional polyurethane (PU) production often relies on solvents to keep the material in a liquid state for application.

These solvents evaporate during the curing process, releasing Volatile Organic Compounds (VOCs) into the atmosphere. VOCs are a major source of air pollution and can pose health risks to factory workers.

KPU, being a solvent-free PU, uses a different process that does not require these volatile chemicals. This directly eliminates a primary source of industrial pollution.

Non-Toxic Final Product

The "non-toxic" and "non-hazardous" labels refer to the finished, cured KPU material.

Because no harsh solvents are used in its creation, there are no residual chemicals to leach out of the final product.

This is why KPU can meet the stringent testing standards of major brands, which often have strict limits on restricted substances in consumer goods like footwear and apparel.

Understanding the Full Environmental Picture

True objectivity requires acknowledging the limitations of any material. While KPU offers a cleaner manufacturing process, it's essential to understand its complete lifecycle.

It's Still a Plastic

At its core, KPU is a type of polyurethane, which is a petroleum-based polymer. It is not derived from renewable resources, nor is it biodegradable.

Its primary environmental benefit is confined to the significant reduction of pollution during its creation.

The End-of-Life Challenge

Like many advanced plastics, KPU products are not easily recycled. At the end of their useful life, they typically end up in landfills.

The "eco-friendly" claim does not extend to its disposal. The material's durability is an advantage for product longevity but a challenge for waste management.

The Nuance of "100% Eco-Friendly"

The claim of being "100% eco-friendly" is a marketing simplification. In material science, no manufactured product has zero environmental impact.

KPU is environmentally friendlier than its solvent-based counterparts. This is a crucial and valuable improvement, but it does not make the material impact-free.

Is KPU the Right Choice for Your Goal?

Selecting the right material depends entirely on which aspect of sustainability is your top priority.

- If your primary focus is reducing manufacturing pollution and ensuring consumer safety: KPU is an excellent choice because its solvent-free process eliminates harmful VOC emissions.

- If your primary focus is using renewable or biodegradable materials: You should explore bio-based or compostable alternatives, as standard KPU is a durable, non-biodegradable plastic.

Ultimately, choosing KPU represents a conscious decision to prioritize clean air and product safety in the manufacturing stage of a product's life.

Summary Table:

| Aspect | KPU Material | Traditional Solvent-Based PU |

|---|---|---|

| Manufacturing Process | Solvent-free, no VOCs released | Uses solvents, releasing harmful VOCs |

| Primary Environmental Benefit | Pollution prevention & worker safety | - |

| Final Product | Non-toxic, no residual chemicals | Potential for residual solvents |

| Biodegradability | Not biodegradable (durable plastic) | Not biodegradable |

| End-of-Life | Typically ends up in landfill | Typically ends up in landfill |

Looking for a manufacturing partner that prioritizes cleaner production and material safety?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, and we specialize in utilizing advanced materials like KPU to meet your sustainability and quality standards.

Let us help you create products that are safer for consumers and the environment. Contact our team today to discuss your next project!

Visual Guide

Related Products

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Wholesale Lightweight Tactical Boots with Dial Closure OEM & Bulk Orders

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Premium Grain Leather Safety Boots for Bulk Supply

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

People Also Ask

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- What are the essential features all work boots should have regardless of gender? Non-Negotiable Safety & Support

- Why is the last important in work boot design? It's the Anatomical Blueprint for Comfort & Safety

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- Why is the use of steel-toe safety footwear critical during the maintenance of sugar factory press chains? Protect Your Team