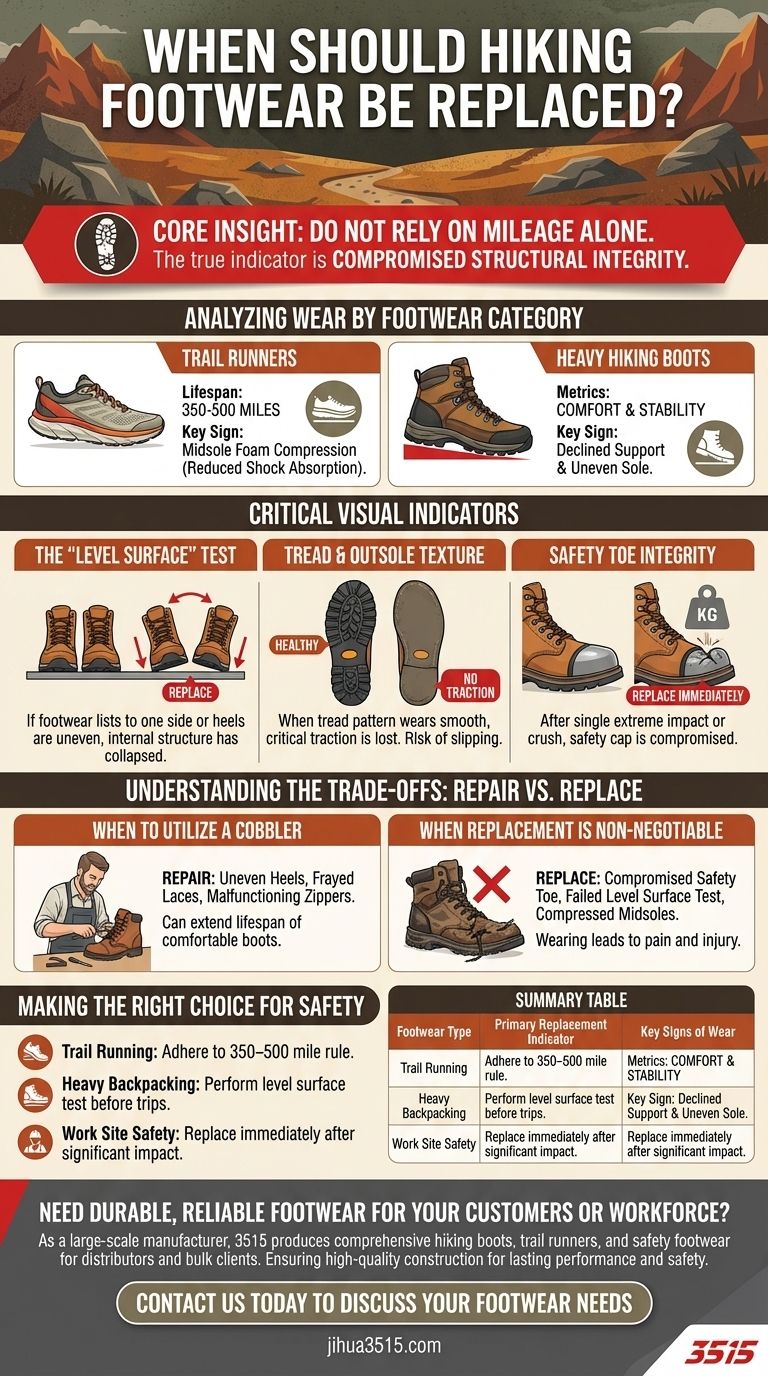

Hiking footwear typically requires replacement when specific mileage benchmarks are met or when physical signs of structural failure appear. Trail runners generally last between 350 to 500 miles, whereas sturdy hiking boots depend more on condition, requiring retirement when they no longer sit flat on a level surface or when the sole texture is worn smooth.

Core Insight: Do not rely on mileage alone to determine the lifespan of your gear. The true indicator of expired footwear is compromised structural integrity—manifested by uneven heel wear, compressed cushioning that causes discomfort, or a safety toe that has sustained a heavy impact.

Analyzing Wear by Footwear Category

Different types of hiking footwear are constructed with varying durabilities. Understanding the specific lifespan of your gear is the first step in maintaining foot health.

Trail Runners and Lightweight Shoes

Trail runners utilize softer, lighter materials that prioritize agility over longevity. Consequently, they degrade faster than traditional boots.

Expect a lifespan of 350 to 500 miles. Beyond this range, the midsole foam usually compresses, reducing shock absorption even if the upper looks intact.

Heavy Hiking Boots

Hiking boots generally offer greater durability due to tougher construction materials. Instead of tracking miles, rely on comfort and stability as your primary metrics.

If the boot no longer feels comfortable or support has visibly declined, it is time to reassess the gear.

Critical Visual Indicators

You can perform simple visual inspections to diagnose the health of your footwear. These tests reveal issues that might not be immediately obvious while walking.

The "Level Surface" Test

Place your boots or shoes on a completely flat, level surface, such as a table or counter.

Observe the heels and the back of the boot. If the footwear lists to one side or the heels look uneven, the internal structure has collapsed, and the boots must be replaced.

Tread and Outsole Texture

Inspect the bottom of the shoe, specifically the texture around the heels and the balls of the feet.

When the tread pattern wears smooth or the texture disappears, you have lost critical traction. This increases the risk of slipping and indicates the material is at the end of its life.

Safety Toe Integrity

For footwear incorporating a safety toe, the rules of replacement are strict.

If the toe experiences a single extreme impact or heavy weight crush, the boot must be replaced immediately. Even if the damage is not visible externally, the structural integrity of the safety cap is likely compromised.

Understanding the Trade-offs: Repair vs. Replace

Not every issue requires tossing the boots in the trash. Distinguishing between cosmetic damage and structural failure can save you money.

When to Utilize a Cobbler

High-quality hiking boots often feature construction that allows for repairs. Professional cobblers can replace unevenly worn heels, fix frayed laces, and repair malfunctioning zippers.

This maintenance can significantly extend the lifespan of a broken-in, comfortable pair of boots.

When Replacement is Non-Negotiable

Repairs cannot fix a compromised safety toe or a shoe that has lost its internal stability (failed the level surface test).

Trying to squeeze extra miles out of footwear with uneven soles or compressed midsoles will alter your gait. This trade-off often leads to knee, hip, or back pain, which is far more costly than a new pair of shoes.

Making the Right Choice for Your Safety

Deciding when to upgrade your gear depends on your specific usage patterns and footwear type.

- If your primary focus is trail running: Adhere strictly to the 350–500 mile rule to ensure your joints are protected from impact.

- If your primary focus is heavy backpacking: Perform the level surface test before every major trip to ensure ankle support remains intact.

- If your primary focus is work site safety: Replace footwear immediately following any significant impact to the safety toe, regardless of age.

Prioritize the structural integrity of your footwear over cost, as your boots are the foundation of your safety on the trail.

Summary Table:

| Footwear Type | Primary Replacement Indicator | Key Signs of Wear |

|---|---|---|

| Trail Runners | Mileage (350-500 miles) | Compressed midsole foam, loss of cushioning |

| Hiking Boots | Structural Integrity | Fails level surface test, loss of stability/comfort |

| Safety-Toe Boots | Impact Damage | Any heavy impact to the toe cap, visible or not |

Need durable, reliable footwear for your customers or workforce?

As a large-scale manufacturer, 3515 produces a comprehensive range of hiking boots, trail runners, and safety footwear for distributors, brand owners, and bulk clients. Our production capabilities ensure high-quality construction for lasting performance and safety.

Contact us today to discuss your footwear needs and explore our catalog.

Visual Guide

Related Products

- Durable Rubber Sole Outdoor Shoes Wholesale & Custom Manufacturing

- Durable Waterproof Rain Boots | Custom Manufacturer for Wholesale & Brands

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- How should one choose between hiking boots and hiking shoes? A Guide to Matching Footwear to Your Trail

- What preparation is needed before taking new boots on a long hike? A Guide to a Pain-Free Break-In

- What role does lacing play in hiking or trekking shoes? Secure Your Fit for Maximum Trail Performance

- Why do blisters occur when feet get wet during a hike? Prevent Painful Foot Blisters on Your Next Trek

- What are the pros and cons of backpacking boots? Essential Support vs. Weight Trade-Offs

- How does hiking speed affect the choice of footwear? Choose the Right Shoe for Your Pace

- What materials are commonly used for trekking shoe uppers? A Guide to Leather vs. Synthetic

- How should hiking boots be stored properly? Protect Your Investment for the Long Trail