To be definitive, you must replace your safety boots immediately after they have sustained an impact from a heavy object. Even if the steel or composite toe shows no visible damage, its structural integrity has been compromised. The boot has performed its protective function once, and it cannot be trusted to do so again.

The core principle is that a safety toe is engineered for a single, significant impact. Relying on it afterward introduces a critical and unacceptable risk of failure. This rule is absolute and supersedes any considerations of the boot's age or outward appearance.

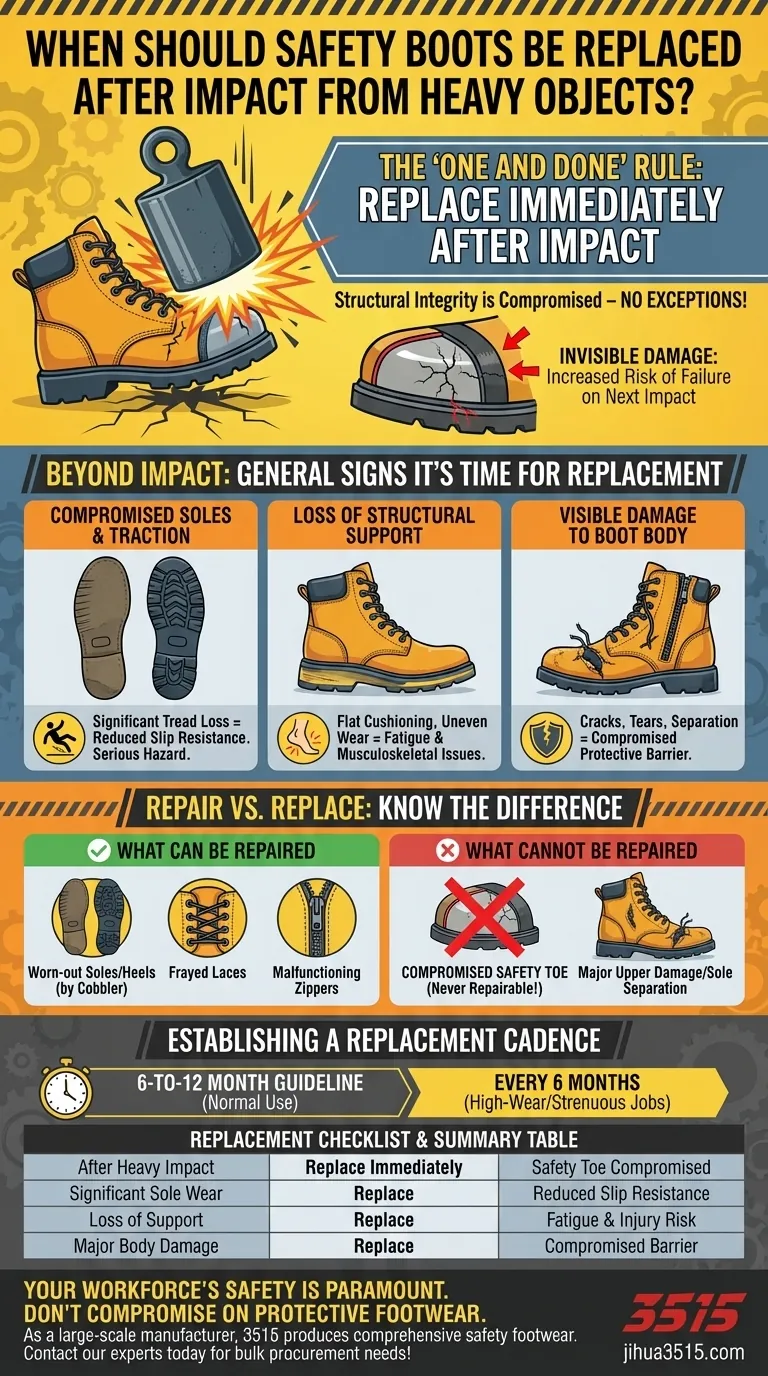

The "One and Done" Rule for Safety Toes

The primary function of a safety boot is to protect you from a specific type of catastrophic event: a compression or impact injury. The components designed to provide this protection are not meant for repeated use.

Why a Single Impact Compromises Protection

When a heavy object strikes the protective toe cap, the materials absorb and distribute a massive amount of force. This event creates micro-fractures in composite materials or can permanently deform a steel toe, even if it springs back into a shape that appears normal. These weaknesses are often invisible to the naked eye.

The Danger of Invisible Damage

You cannot visually inspect a safety toe and confirm its integrity after a major impact. The boot has effectively "spent" its protective capacity. Wearing it again is a gamble, as a second impact—even one of lesser force—could lead to a complete failure of the compromised toe cap.

Beyond Impact: General Signs It's Time for Replacement

Even without a specific impact event, all work boots have a finite lifespan. Regular inspection for general wear and tear is crucial for maintaining safety and comfort.

Compromised Soles and Traction

The most obvious sign of wear is on the sole. Look for a significant loss of tread depth, especially around the heel and the ball of the foot. When the texture on the bottom is worn smooth, your slip resistance is drastically reduced, creating a serious hazard.

Loss of Structural Support

Your boots provide critical support for your feet and ankles. If the cushioning feels compressed and no longer supportive, or if the heel and sole are wearing unevenly, the boot's structure is failing. This can lead to fatigue and musculoskeletal issues.

Visible Damage to the Boot Body

Cracks, tears, or deep cuts in the boot's upper material compromise its protective barrier. Frayed laces, malfunctioning zippers, or seams that are beginning to separate are also clear indicators that the boot is nearing the end of its life.

Understanding the Trade-offs: Repair vs. Replace

Knowing when a boot can be salvaged versus when it must be discarded is key to both safety and economy.

What Can Be Repaired

Minor issues on an otherwise sound boot can often be addressed. A professional cobbler can frequently replace worn-out soles or heels, and you can easily replace frayed laces or malfunctioning zippers yourself. These repairs can extend the usable life of the boot's upper.

What Cannot Be Repaired

A compromised safety toe is never repairable. Any boot that has sustained a significant impact must be replaced. Likewise, major damage to the boot's upper, such as large tears or separation from the sole, typically means the boot is structurally unsound and should be retired.

Establishing a Replacement Cadence

While daily inspection is vital, having a general timeline for replacement ensures you don't wear unsafe equipment.

The 6-to-12 Month Guideline

For most jobs, safety boots should be replaced every 6 to 12 months. This is a widely accepted industry standard that accounts for the typical degradation of materials under normal work stress.

Adjusting for Your Environment

If you work in a particularly high-wear environment or in exceptional weather conditions, you must shorten that timeline. For strenuous jobs in construction, manufacturing, or outdoor industries, plan on replacing your boots every six months to maintain optimal safety and support.

Making the Right Call: Your Replacement Checklist

Use these guidelines to make a clear, objective decision about your footwear.

- If your primary focus is recovering from an impact: Replace the boots immediately, period. Their most critical safety feature is now unreliable.

- If your primary focus is daily safety in a high-intensity job: Plan to replace your boots every six months and perform weekly inspections for wear.

- If your primary focus is mitigating slip-and-fall risks: Replace your boots as soon as you notice significant loss of tread or uneven wear on the soles.

- If your primary focus is long-term comfort and support: Replace your boots when the internal cushioning feels flat or the structure no longer supports your ankle properly.

Your safety footwear is non-negotiable personal protective equipment; treat its integrity with the seriousness it deserves.

Summary Table:

| Replacement Scenario | Action Required | Key Reason |

|---|---|---|

| After a heavy impact | Replace Immediately | The safety toe's structural integrity is compromised. |

| Significant sole/tread wear | Replace | Drastically reduced slip resistance. |

| Loss of structural support | Replace | Leads to fatigue and potential injury. |

| Major damage to upper material | Replace | Compromises the boot's protective barrier. |

Your workforce's safety is paramount. Don't compromise on protective footwear.

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, engineered for maximum impact protection and durability.

Ensure your team is equipped with reliable, high-quality safety boots that meet the strictest standards. Contact our experts today to discuss your bulk procurement needs and find the perfect safety solution for your industry.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Grain Leather Safety Boots for Bulk Supply

- Wholesale Slip-On Safety Boots Manufacturer - Custom Puncture-Proof & Steel Toe

- Premium Waterproof Nubuck Safety Boots for Wholesale

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

People Also Ask

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- What materials are used for safety toes? Choose Steel, Composite, or Aluminum for Your Work Boots

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene