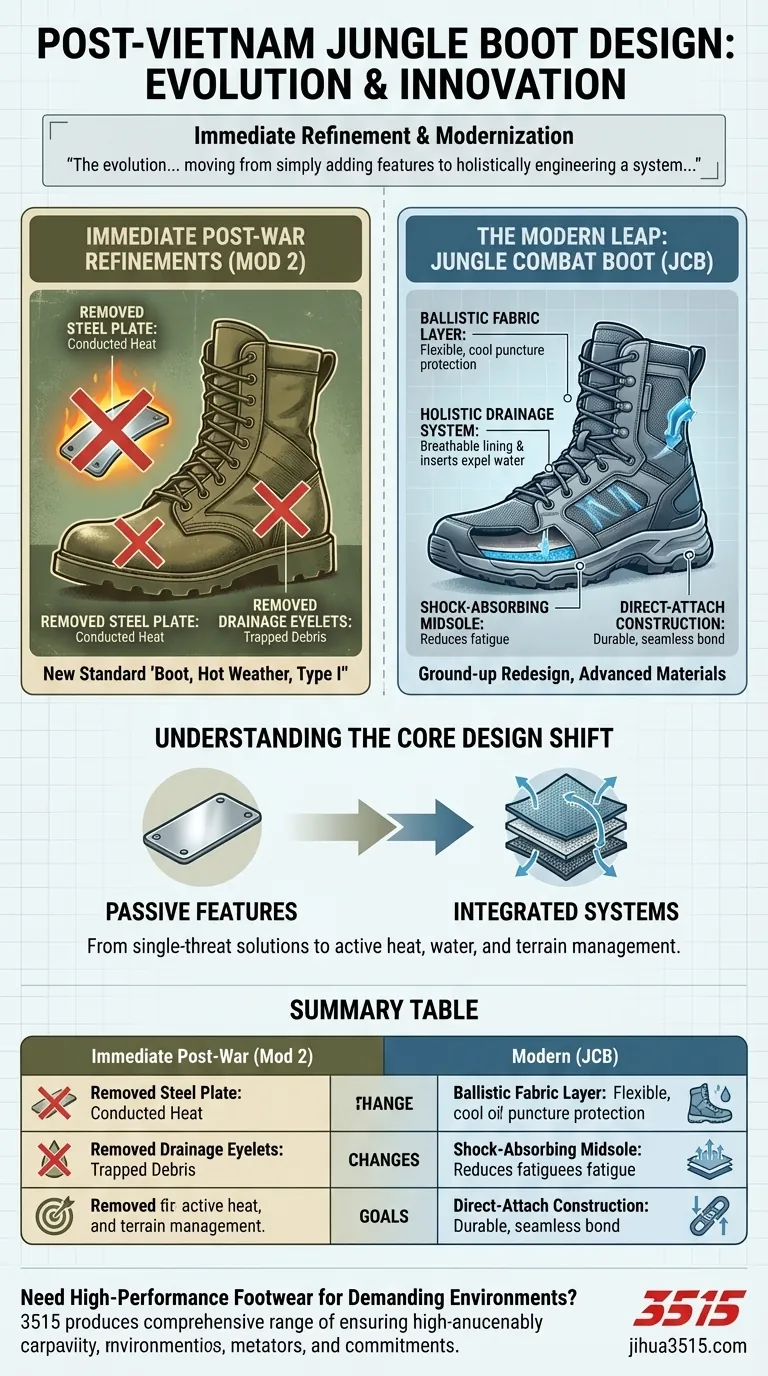

Immediately following the Vietnam War, jungle boot design underwent an initial refinement phase that eliminated problematic features, followed by a much later, comprehensive modernization that integrated advanced materials and construction techniques. The first changes removed the steel plate and drainage eyelets, while later designs like the Jungle Combat Boot (JCB) completely re-engineered the footwear for superior performance.

The evolution of the jungle boot demonstrates a critical shift in design philosophy: moving from simply adding features for protection to holistically engineering a system that enhances soldier performance by managing heat, water, and terrain more effectively.

Immediate Post-War Refinements

The initial changes to the jungle boot were reactive, addressing specific, well-documented failures identified during the Vietnam War.

The New Standard Issue

Following the war, the jungle boot design became the standard 'Boot, Hot Weather, Type I'. This boot was intended for general use in mild to hot-wet climates, establishing its role beyond the specific jungles of Southeast Asia.

Eliminating the Steel Plate

The "Mod 2" version of the post-war boot removed the steel puncture-protection plate. While intended to stop punji sticks, the steel plate was found to conduct and retain heat, effectively cooking the soldier's foot in hot conditions.

Removing Drainage Eyelets

The same "Mod 2" update also eliminated the iconic drainage eyelets on the instep. Field experience proved these vents allowed sand, mud, and small debris to enter the boot, often causing more irritation and injury than the water they were meant to drain.

The Modern Leap: The Jungle Combat Boot (JCB)

Decades later, the Jungle Combat Boot (JCB) represented a ground-up redesign, applying modern technology to solve the original problems more intelligently.

Rethinking Puncture Protection

Instead of a heat-conducting steel plate, the JCB uses a puncture-resistant ballistic fabric layer. This provides flexible protection without the thermal penalty, keeping the foot safer and cooler.

Superior Drainage and Drying

The JCB features a holistic water management system. It includes additional drainage holes, a breathable inner lining, and an improved water-draining insert that work together to expel water and dry the boot much faster.

Enhancing Sole Performance

The JCB retains the classic mud-shedding "Panama style" outsole but integrates a modern, shock-absorbing midsole. This significantly reduces fatigue and improves comfort during long movements.

Modernizing Construction and Stability

The boot's upper and sole are joined with a direct-attach construction, using liquid foam to create a durable, seamless bond. A lower heel height prevents snagging on vines, while speed laces and a redesigned upper improve fit and function.

Understanding the Core Design Shift

The evolution from the post-Vietnam boot to the modern JCB highlights a deeper understanding of the environmental challenges.

From Passive Features to Integrated Systems

The original boot had separate, passive features like a steel plate and simple holes. The JCB integrates materials like ballistic fabric and breathable liners into a complete system that actively manages protection and moisture.

Solving the Root Problem

Simply removing the old eyelets solved the problem of debris entry but didn't optimize water removal. The JCB's multi-part drainage system shows a focus on solving the root problem: getting water out and drying the foot's environment as quickly as possible.

Heat and Mobility as Priorities

The primary driver of change was the recognition that heat and mobility are as critical as protection. Removing the steel plate and adding a cushioned midsole directly address soldier performance and endurance, not just surviving a single threat.

Key Takeaways in Jungle Boot Evolution

To understand the progression, consider the distinct goals of each design phase.

- If your primary focus is on early improvements: The key takeaway is the "Mod 2" boot, which corrected the most immediate flaws of the Vietnam-era design by removing the heat-conducting steel plate and debris-trapping eyelets.

- If your primary focus is on modern innovation: The Jungle Combat Boot (JCB) is the prime example, showcasing how new materials and construction methods can create a far superior solution for hot, wet environments.

Ultimately, the journey of the jungle boot is a lesson in how direct user feedback and material science combine to drive meaningful innovation.

Summary Table:

| Era | Key Changes | Primary Goal |

|---|---|---|

| Immediate Post-War (Mod 2) | Removed steel plate & drainage eyelets | Correct immediate flaws (heat, debris) |

| Modern (JCB) | Puncture-resistant fabric, integrated drainage, shock-absorbing midsole | Holistic performance: protection, cooling, drying, mobility |

Need High-Performance Footwear for Demanding Environments?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including modern designs inspired by the latest innovations in durability, comfort, and functionality.

Let us help you equip your team or develop your next product line. Contact our experts today to discuss your specific needs and how we can deliver value through quality manufacturing.

Visual Guide

Related Products

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Durable Leather Tactical Boots Wholesale & Custom Manufacturing for Brands

- Wholesale Lightweight Tactical Boots with Dial Closure OEM & Bulk Orders

- Durable Leather High-Ankle Tactical Boots for Wholesale & Custom Manufacturing

- Durable High-Ankle Tactical Boots Wholesale Manufacturer for Custom & Bulk Orders

People Also Ask

- What are the advantages and disadvantages of waterproof tactical boots? A Guide to the Key Trade-Offs

- Why is waterproofing important in tactical boots? Essential for Foot Health & Mission Success

- Are military camouflage boots waterproof? How to Choose Boots That Keep Feet Dry

- What waterproof technology is used in tactical boots? Unlock All-Weather Performance & Protection

- Why is waterproofing important for tactical boots? Protect Your Feet and Gear in Any Mission