In certain career fields, the common practice for boot maintenance was a two-part system dictated by practicality. Given the constant exposure to dirt, oil, and hydraulic fluid, maintaining a single pair of shiny boots was considered impossible. Personnel would therefore maintain two separate pairs: a pristine pair for appearances and a durable, functional pair for actual labor.

The core challenge was the conflict between the need for a professional, polished appearance and the harsh reality of the work environment. The practical solution was to separate the concepts of "show boots" and "work boots" entirely.

The Core Conflict: Appearance vs. Functionality

The two-boot system wasn't a matter of preference; it was a necessary adaptation to conflicting demands. It allowed personnel to satisfy uniform standards without sacrificing the utility of their primary work equipment.

The Demands of the Work Environment

In many technical and industrial fields, boots are inevitably exposed to substances that ruin a polished finish.

Dirt, grease, oil, and hydraulic fluids don't just scuff a boot; they can degrade the leather and make a high-gloss shine impossible to maintain. Constant cleaning and polishing of a single pair would be a futile and time-consuming daily effort.

The Need for a Professional Image

Despite the nature of the work, personnel were often still subject to uniform inspections and the expectation of a sharp, professional appearance.

A clean, well-maintained uniform, including polished boots, is a staple of many professional organizations. This standard doesn't disappear just because the daily work is messy.

A Practical Solution Emerges

The most logical resolution was to stop treating them as the same piece of equipment.

By dedicating one pair for appearance and another for labor, individuals could meet both requirements efficiently. The "show" pair could be kept in perfect condition, while the "work" pair could be maintained for safety and durability.

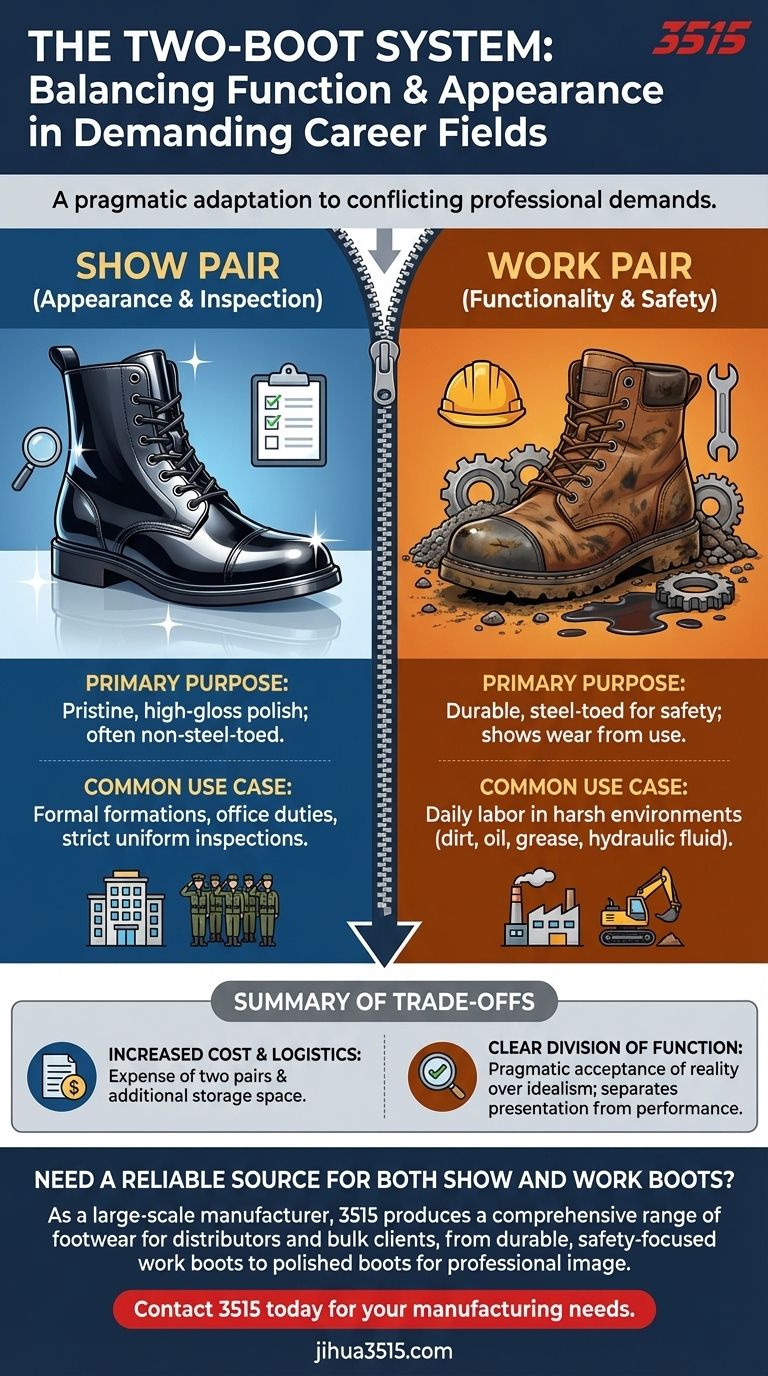

Understanding the Two-Boot System

This system created a clear distinction between boots meant to be seen and boots meant to be used. Each pair served a distinct and separate purpose.

The "Show" Pair

This pair was often non-steel-toed, as it wasn't intended for hazardous environments. Its sole purpose was to pass inspection.

These boots were meticulously cared for, receiving the high-gloss polish and attention to detail required to meet strict appearance standards. They were worn for formations, office duties, or any situation where a formal appearance was required.

The "Work" Pair

The work boots were the true tools of the trade. They were typically steel-toed for safety and built for durability.

Their condition reflected their use. While they were kept clean and serviceable for safety reasons, maintaining a cosmetic shine was not the priority. Scuffs, stains, and wear were accepted as evidence of work performed.

Understanding the Trade-offs

While effective, this approach was not without its own set of challenges. It required more effort and resources than a single-boot system.

Increased Cost and Logistics

The most obvious downside was the personal expense and effort of purchasing and maintaining two separate pairs of boots. This also required additional storage space for the extra pair.

A Clear Division of Function

This system forces a clear mental line between presentation and performance. It acknowledges that the equipment best suited for a harsh job is rarely the same equipment that looks best on parade. This is a pragmatic acceptance of reality over idealism.

Applying This Principle Today

This practice reveals a timeless principle about balancing professional standards with the realities of demanding work.

- If your primary focus is meeting appearance standards: Recognize that dedicating specific gear just for "show" is often the most efficient way to succeed in a physically demanding field.

- If your primary focus is functionality and safety: Prioritize equipment designed for the task at hand, and accept that wear and tear is a sign of its utility, not a lack of discipline.

Ultimately, this system demonstrates a highly effective, pragmatic approach to navigating conflicting professional demands.

Summary Table:

| Boot Type | Primary Purpose | Key Characteristics | Common Use Case |

|---|---|---|---|

| Show Boots | Appearance & Inspection | Pristine, high-gloss polish; often non-steel-toed | Formal formations, office duties, inspections |

| Work Boots | Functionality & Safety | Durable, steel-toed; shows wear from use | Daily labor in harsh environments (dirt, oil, grease) |

Need a Reliable Source for Both Show and Work Boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, from durable, safety-focused work boots to polished boots perfect for maintaining a professional image.

Let us be your single-source supplier to efficiently meet both your functional and appearance needs.

Contact 3515 today to discuss your specific requirements and benefit from our extensive manufacturing expertise.

Visual Guide

Related Products

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Custom OEM Training Shoes Wholesale Manufacturer Durable & Breathable

- Premium Wholesale Tactical Style Safety Shoes Boots with Quick Lacing

People Also Ask

- What features should work boots have for electrical hazard protection? Essential EH-Rated Boot Requirements

- What are the temperature ratings and recommended uses for 400g insulated boots? Your Guide to Winter Warmth

- Why is comfort important in work boots? The Critical Link Between Comfort and Safety

- How can proper care extend the lifespan of work boots? Maximize Durability & Safety

- What are the cons of Goodyear Welt Construction? The Truth About Cost, Weight, and Comfort

- How does industrial footwear contribute to worker safety in palm oil sterilizer kettle stations? Essential Heat Defense

- Why are slip-resistant soles important in mining boots? Prevent Slips and Falls in Hazardous Conditions

- How does cleaning your work boots help in their maintenance? Extend Lifespan & Boost Safety