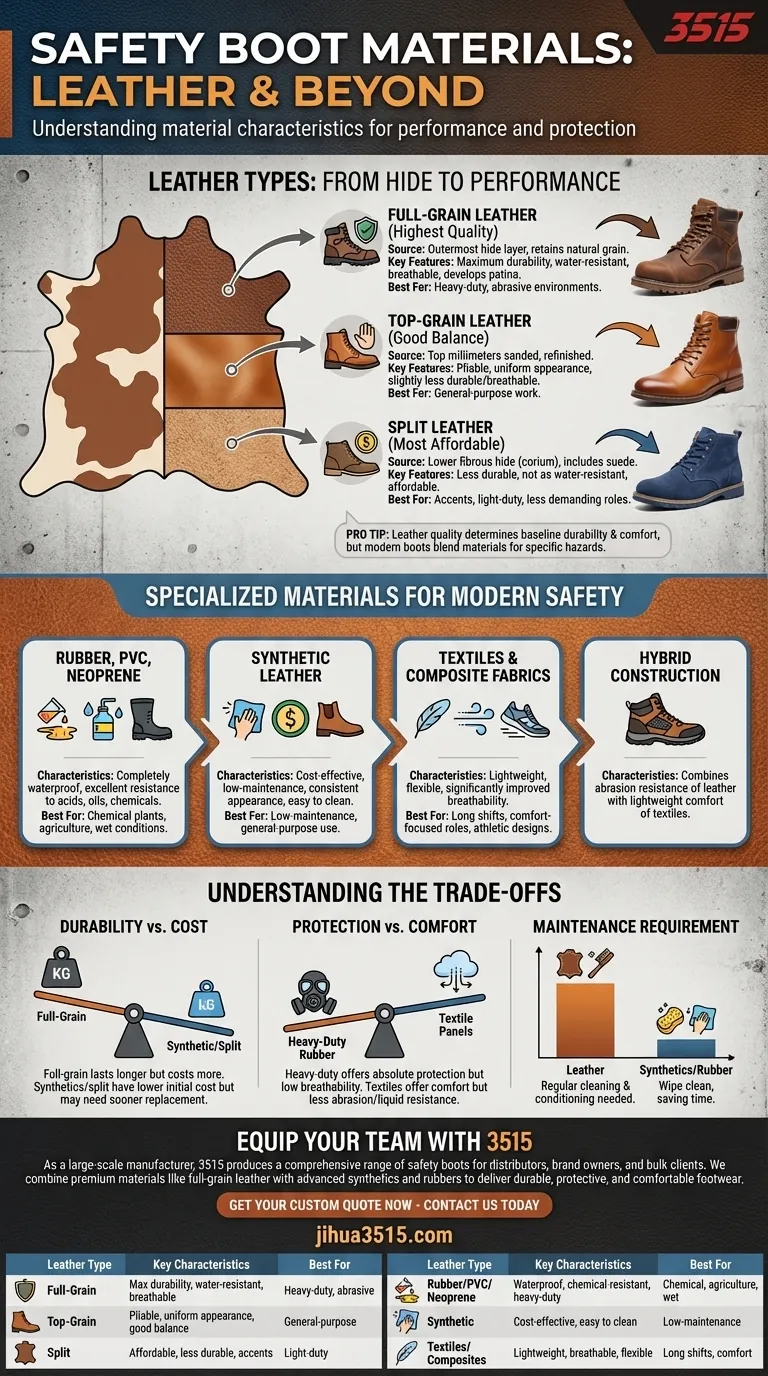

In safety boots, the most common leather types are full-grain, top-grain, and split leather. Full-grain leather is the highest quality, offering maximum durability and breathability because it comes from the outermost layer of the hide. Top-grain leather is slightly more processed and pliable, while split leather is the most affordable but least durable option, often used in lighter-duty footwear.

The specific type of leather determines a boot's baseline durability and comfort, but the true measure of its performance comes from understanding how that leather is combined with specialized materials like rubber and synthetics to protect against specific workplace hazards.

A Closer Look at Leather Types

Understanding the source of the leather is the first step in evaluating a safety boot's construction. Each type comes from a different layer of the animal hide, which directly impacts its performance characteristics.

Full-Grain Leather

This is the highest grade of leather available. It is taken from the top layer of the hide and includes the complete, natural grain.

Because it is not sanded or buffed, full-grain leather retains its inherent toughness, making it the most durable and water-resistant type of leather. It also develops a unique patina over time.

Top-Grain Leather

Top-grain leather is the second-highest quality. The top few millimeters of the hide are sanded and refinished to remove imperfections.

This process makes the leather more pliable and gives it a uniform appearance, but it also slightly reduces its durability and breathability compared to full-grain.

Split Leather

Split leather is created from the lower, fibrous part of the hide (the "corium") that is left once the top-grain is separated.

This material, which includes suede, is less durable and not as water-resistant as the higher grades. It is more affordable and is often used for accents or in boots designed for less demanding environments.

Beyond Leather: Specialized Materials for Modern Safety

While leather forms the foundation of many safety boots, modern footwear is a system of materials designed for specific environments. The most effective boots often blend leather with other components to enhance protection.

Rubber, PVC, and Neoprene

For environments with significant exposure to liquids, these materials are critical. Rubber and PVC are completely waterproof and offer excellent resistance to many acids, oils, and industrial chemicals.

They are most commonly found in boots designed for chemical plants, agriculture, or heavy-duty cleaning, where leather would quickly degrade. Neoprene offers similar protection with added flexibility.

Synthetic Leather

Synthetic leather provides a cost-effective and low-maintenance alternative to natural leather. It offers a consistent appearance and is easy to clean.

While not as breathable or durable as high-quality full-grain leather, it provides reliable performance and is a practical choice for many general-purpose work boots.

Textiles and Composite Fabrics

Many modern boots incorporate panels of high-strength textile or composite fabrics. These materials are used to reduce weight, increase flexibility, and significantly improve breathability.

This hybrid construction combines the abrasion resistance of leather in high-wear areas with the lightweight comfort of textiles elsewhere, creating a more athletic and comfortable boot.

Understanding the Trade-offs

No single material is superior in all situations. Choosing the right boot requires balancing its intended use against its material properties.

Durability vs. Cost

Full-grain leather offers the longest service life but comes at the highest price. Synthetic and split leathers reduce the initial cost but will likely need to be replaced sooner under heavy use.

Protection vs. Comfort

A heavy-duty rubber boot provides absolute protection from chemicals but offers very little breathability, which can be uncomfortable over a long shift. A boot with textile panels is far more comfortable but may not offer the same level of protection against abrasion or liquids.

The Importance of Maintenance

All-leather boots, particularly full-grain, require regular cleaning and conditioning to maintain their water resistance and prevent the material from drying out and cracking. In contrast, synthetics and rubber require little more than being wiped clean, saving time and effort.

Selecting the Right Boot for Your Environment

Your choice should be dictated by the primary hazards and conditions of your workplace.

- If your primary focus is maximum durability and longevity in dry, abrasive conditions: Choose a boot made predominantly from full-grain leather.

- If your primary focus is protection from water, oils, or chemicals: Look for boots constructed from rubber, PVC, or specially treated leather.

- If your primary focus is affordability and easy maintenance for general-purpose work: Consider boots made from top-grain or high-quality synthetic leather.

- If your primary focus is lightweight comfort and breathability for long shifts on your feet: Seek out hybrid designs that strategically combine leather with textile panels.

Understanding these material trade-offs empowers you to select a boot that performs as a true piece of safety equipment tailored to your needs.

Summary Table:

| Leather Type | Key Characteristics | Best For |

|---|---|---|

| Full-Grain Leather | Maximum durability, water-resistant, breathable | Heavy-duty, abrasive environments |

| Top-Grain Leather | Pliable, uniform appearance, slightly less durable | General-purpose work with good balance |

| Split Leather | Affordable, less durable, used in accents or light-duty | Less demanding work environments |

| Rubber/PVC/Neoprene | Waterproof, chemical-resistant, heavy-duty protection | Chemical plants, agriculture, wet conditions |

| Synthetic Leather | Cost-effective, easy to clean, consistent appearance | Low-maintenance, general-purpose use |

| Textiles/Composites | Lightweight, breathable, flexible | Long shifts, comfort-focused roles |

Ready to Equip Your Team with the Right Safety Footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety boots and work footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, tailored to your specific workplace hazards and comfort requirements.

We combine premium materials like full-grain leather with advanced synthetics and rubbers to deliver durable, protective, and comfortable footwear that meets the highest safety standards.

Contact us today to discuss your needs and get a custom quote for your next order. Let us help you protect your workforce with footwear built to last.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Grain Leather Safety Boots for Bulk Supply

- Wholesale Slip-On Safety Boots Manufacturer - Custom Puncture-Proof & Steel Toe

- Premium Waterproof Nubuck Safety Boots for Wholesale

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- Can heavy duty work boots be worn daily outside of work? Discover Durable, All-Day Comfort

- What materials are used for safety toes? Choose Steel, Composite, or Aluminum for Your Work Boots

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene