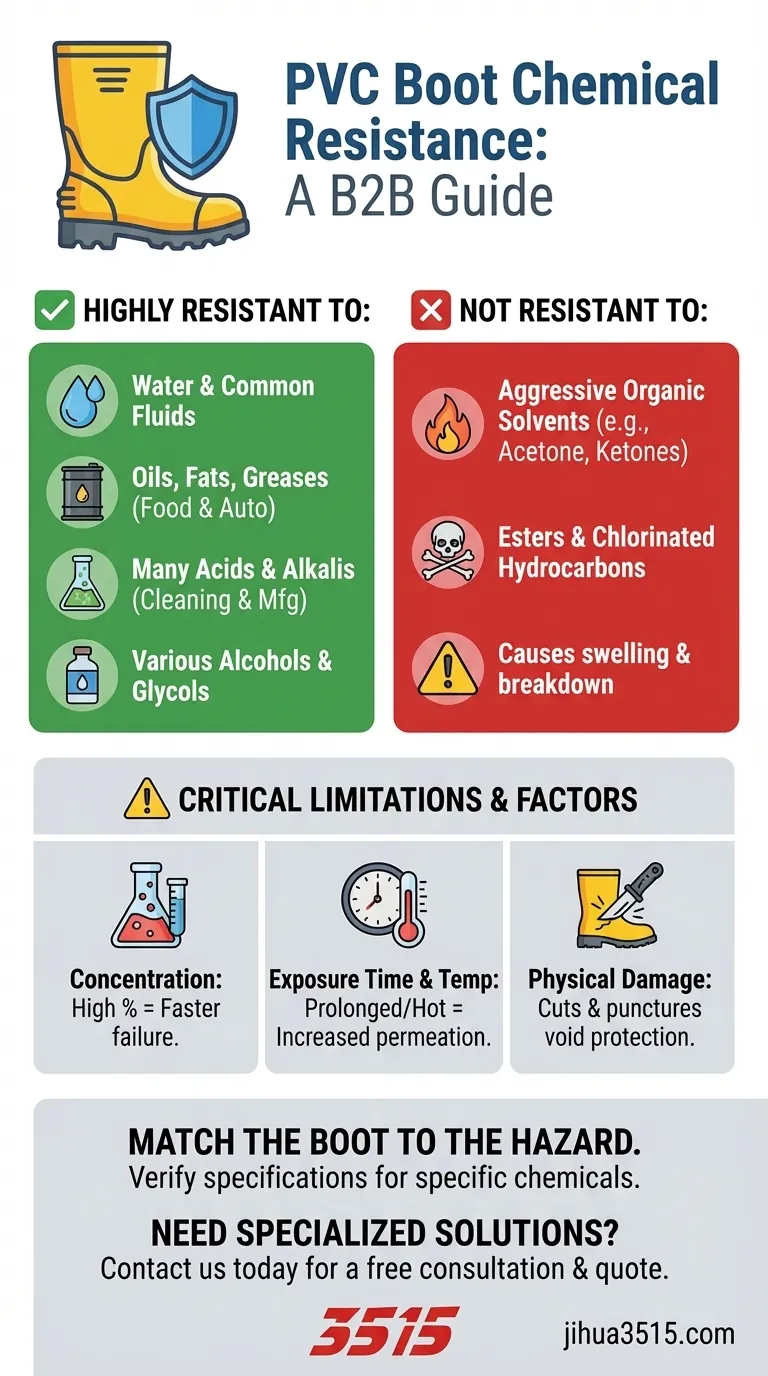

To put it simply, PVC boots are highly resistant to a wide range of common industrial substances. They reliably protect against water, many acids, alkalis, oils, fats, greases, and various alcohols.

While PVC offers excellent general-purpose protection, its effectiveness is not universal. True safety lies in understanding that resistance depends entirely on the specific chemical, its concentration, and the duration of exposure.

The Protective Profile of PVC

Polyvinyl Chloride (PVC) is a synthetic polymer valued for its durability and inherent chemical stability. Its molecular structure creates a non-porous barrier that prevents many hazardous substances from reaching the wearer's skin.

Resistance to Hydrocarbons (Oils and Greases)

PVC excels in environments with oils, fats, and greases, such as food processing plants, garages, and industrial kitchens. The material does not readily absorb these substances, preventing it from swelling, weakening, or degrading.

Resistance to Common Acids and Alkalis

PVC holds up well against many common inorganic acids and alkalis (bases). This makes it a suitable choice for janitorial work, certain manufacturing processes, and agricultural tasks where these types of chemicals are frequently used.

Resistance to Alcohols and Glycols

The material is also generally resistant to a wide range of alcohols and glycols. This property adds to its versatility across different industrial and cleaning applications.

Understanding the Trade-offs and Limitations

No material is completely immune to all chemicals. Understanding the limitations of PVC is critical for ensuring workplace safety and selecting the appropriate Personal Protective Equipment (PPE).

High-Risk: Aggressive Organic Solvents

The primary weakness of PVC is its vulnerability to certain organic solvents. Strong solvents like ketones (e.g., acetone), esters, and chlorinated hydrocarbons (e.g., methylene chloride) can cause the PVC to swell, soften, and break down, completely compromising its protective barrier.

The Critical Factor of Concentration

A boot's resistance to a chemical is highly dependent on that chemical's concentration. A PVC boot might be rated as excellent for a 10% solution of an acid but may fail quickly when exposed to a 70% solution of the same acid.

Exposure Time and Temperature

Resistance ratings assume a specific duration of contact and temperature. A boot that can handle a brief splash may not be suitable for prolonged immersion. Likewise, higher temperatures can often accelerate chemical reactions and increase permeation.

Physical Damage Compromises Safety

Finally, the chemical resistance of any boot is voided if it is physically damaged. Cuts, punctures, or significant abrasion can create a direct path for chemicals to bypass the protective layer.

How to Apply This to Your Project

Making the right choice requires matching the boot's known capabilities to the specific hazards you face. Always start by identifying the exact chemicals present in your environment.

- If your primary focus is on oils, greases, water, and common cleaning agents: PVC is an excellent, reliable, and cost-effective choice for these applications.

- If your work involves aggressive organic solvents, ketones, or esters: You must look beyond PVC and consider specialized materials like nitrile or butyl rubber boots.

- If you work with highly concentrated acids or alkalis: Do not assume resistance. Always consult the manufacturer's specific chemical resistance chart before using PVC boots.

Ultimately, verifying your boot's specifications against the specific chemical hazards of your job is the only way to guarantee safety.

Summary Table:

| PVC Boots Are Resistant To | PVC Boots Are NOT Resistant To |

|---|---|

| Water, Many Acids & Alkalis | Aggressive Organic Solvents (e.g., Acetone) |

| Oils, Fats, and Greases | Ketones and Esters |

| Various Alcohols and Glycols | Chlorinated Hydrocarbons |

Ensure your team's safety with the right chemical-resistant footwear.

As a large-scale manufacturer, 3515 produces a comprehensive range of PVC and other specialized safety boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of industrial footwear, ensuring you get the perfect match for your specific chemical hazards.

Contact us today to discuss your requirements and receive a personalized recommendation. Let us help you protect your workforce effectively.

➡️ Get a Free Consultation & Quote

Visual Guide

Related Products

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium KPU Injection Athletic Style Safety Shoes

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- Why is the use of steel-toe safety footwear critical during the maintenance of sugar factory press chains? Protect Your Team

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management