The Goodyear welting process is a meticulous, multi-stage assembly method prized in high-quality footwear. It begins by stretching the leather upper over a mold called a last. A canvas rib is then attached to the insole, creating an anchor point to which a strip of leather—the welt—is sewn, locking the upper in place. The cavity created is filled with cork for cushioning before the final outsole is stitched directly to the welt, creating a durable and easily repairable shoe.

The core principle of a Goodyear welt is not just about attaching a sole; it is an architectural method that isolates the upper from the outsole. By using the welt as an intermediary, the shoe can be repeatedly resoled without compromising the integrity of the main body, ensuring exceptional longevity.

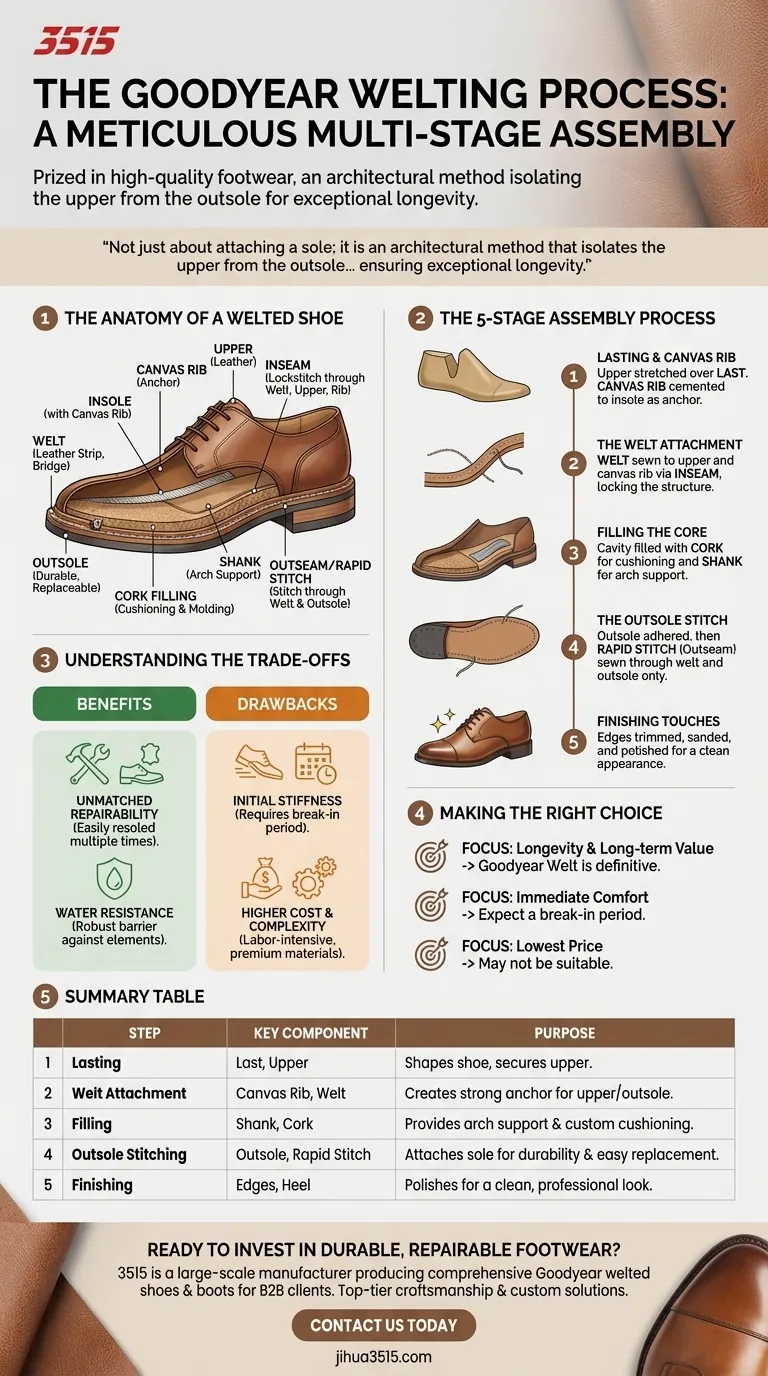

The Anatomy of a Welted Shoe

To understand the assembly, you must first understand the key components that differentiate this construction method. Each piece serves a distinct structural or functional purpose.

The Foundation: Lasting and the Canvas Rib

The entire process begins with the last, a foot-shaped form that dictates the shoe's final shape. The leather upper is stretched tightly over this last and temporarily tacked down.

A crucial and often unseen component is then added: a canvas rib is cemented to the perimeter of the insole. This rib acts as a durable, flexible wall and the primary anchor point for the shoe's most important stitch.

The Critical Link: The Welt

The welt is a long strip of leather, roughly 1.5cm wide. It is the defining feature of this construction method, acting as the bridge between the shoe's upper and its outsole.

Using a specific lockstitch, the welt, the edge of the upper, and the canvas rib are all sewn together. This is the inseam, and it creates a remarkably strong, unified structure.

The Core: Shank and Cork Filling

With the upper and welt secured, a cavity exists between the insole and the future outsole. This space is first fitted with a shank—typically a small piece of wood or steel—that sits under the arch of the foot to provide structural support and prevent the shoe from flexing in the wrong place.

The rest of the cavity is then filled with a layer of granulated cork. This material provides excellent cushioning and, over time, compresses and molds to the unique shape of the wearer's foot, creating a custom-like fit.

The Final Assembly

Once the core structure is complete, the final steps focus on attaching the outsole and finishing the shoe. This is where the repairability of the Goodyear welt becomes evident.

Creating the Bond: The Outsole Stitch

The outsole is first attached with a strong adhesive, like contact cement, to hold it in place.

The final, visible stitch, often called the rapid stitch or outseam, is then sewn through the welt and the outsole. Crucially, this stitch does not penetrate the insole or the upper, keeping the interior of the shoe sealed.

Finishing Touches

Finally, the edges of the sole and heel are trimmed, sanded, and polished to create a smooth, clean appearance. This meticulous finishing work is a hallmark of a well-made shoe.

Understanding the Trade-offs

The Goodyear welting method is revered for its benefits, but it is essential to understand its inherent characteristics to make an informed decision.

Benefit: Unmatched Repairability

Because the outsole is stitched only to the welt, a cobbler can easily remove an old sole and sew on a new one. This can be done multiple times without ever disturbing the shoe's upper, dramatically extending its lifespan.

Benefit: Water Resistance

The welt creates a more robust barrier between the ground and the wearer's foot compared to simpler construction methods. While not fully waterproof, it offers superior protection from the elements.

Drawback: Initial Stiffness and Break-in Period

The multiple layers of leather, cork, and robust stitching create a shoe that is initially quite stiff. Goodyear welted shoes almost always require a break-in period as the cork molds and the leather flexes.

Drawback: Higher Cost and Complexity

This construction is more labor-intensive and requires more high-quality materials than cemented or Blake-stitched shoes. This complexity, whether performed by machine or by hand for bespoke footwear, results in a higher initial purchase price.

Making the Right Choice for Your Goal

Deciding if a Goodyear welted shoe is right for you depends entirely on your priorities.

- If your primary focus is longevity and long-term value: The Goodyear welt is the definitive choice, as its repairability allows a single pair of shoes to last for decades.

- If your primary focus is immediate, out-of-the-box comfort: You should be prepared for a necessary break-in period, as the robust construction needs time to conform to your foot.

- If your primary focus is finding the lowest possible price: This construction method represents a significant upfront investment and may not be the most suitable option.

Understanding the Goodyear welt transforms a simple purchase into a long-term investment in quality and craftsmanship.

Summary Table:

| Step | Key Component | Purpose |

|---|---|---|

| 1. Lasting | Last, Upper | Shapes the shoe and secures the upper. |

| 2. Welt Attachment | Canvas Rib, Welt | Creates a strong anchor for the upper and outsole. |

| 3. Filling | Shank, Cork | Provides arch support and custom cushioning. |

| 4. Outsole Stitching | Outsole, Rapid Stitch | Attaches the sole for durability and easy replacement. |

| 5. Finishing | Edges, Heel | Polishes the shoe for a clean, professional look. |

Ready to invest in durable, repairable footwear? As a large-scale manufacturer, 3515 produces a comprehensive range of Goodyear welted shoes and boots for distributors, brand owners, and bulk clients. Our expertise ensures top-tier craftsmanship, longevity, and custom solutions tailored to your needs. Contact us today to discuss your production requirements and elevate your footwear line with quality that lasts!

Visual Guide

Related Products

- Wholesale Comfortable Business Casual Shoes Custom Manufacturing

- Custom Manufactured Air Cushion Leather Business Shoes for Wholesale

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Durable & Breathable Training Shoes for Custom Brands

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

People Also Ask

- How can one balance a casual outfit when wearing dress shoes? Achieve a Polished Smart Casual Look

- What are the long-term benefits of investing in quality dress shoes? Save Money & Boost Your Style

- Are brown dress shoes appropriate for formal events? A Guide to Choosing the Right Shoe

- What types of dress shoes are recommended for formal occasions? A Guide to Impeccable Style

- What are the key considerations when choosing dress shoes for formal occasions? A Guide to Style, Color & Quality