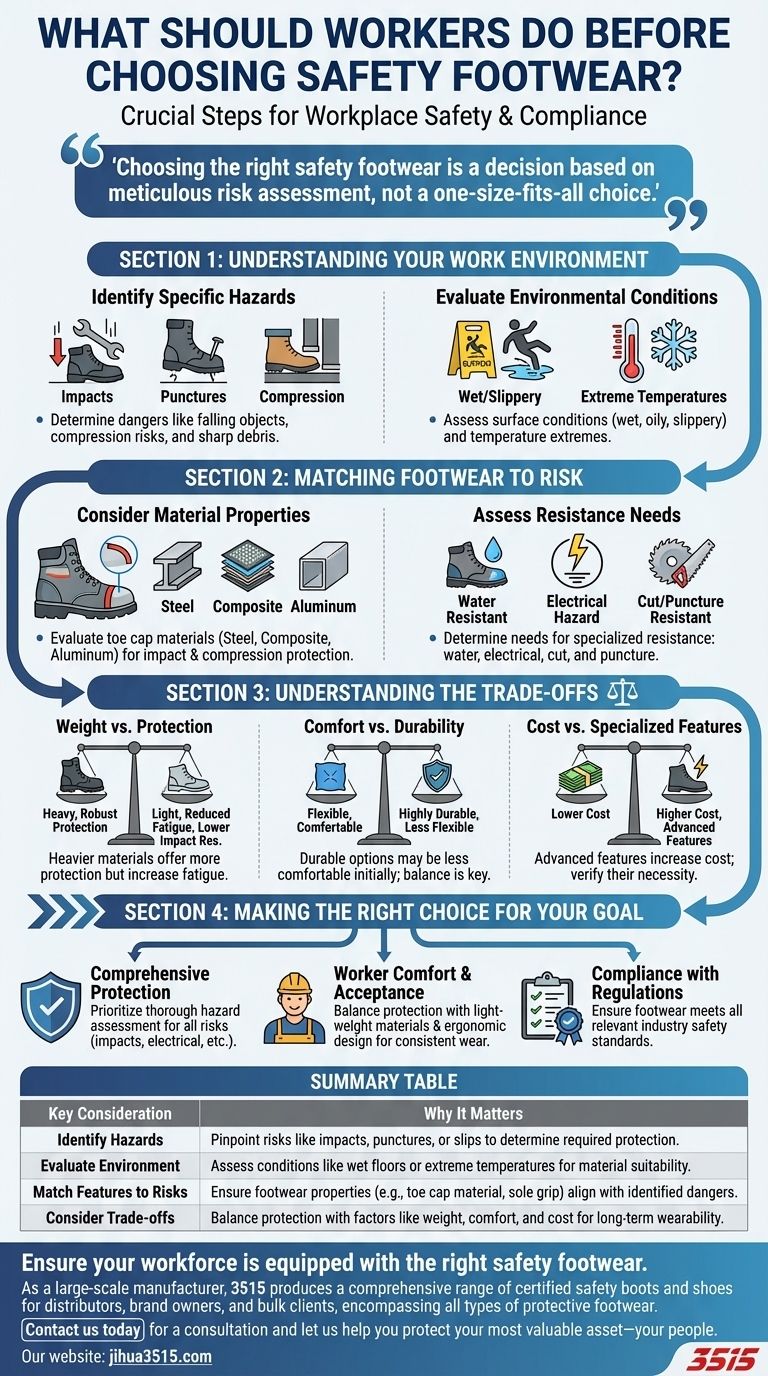

Before choosing safety footwear, workers must first thoroughly identify and understand the specific hazards present in their work environment. This critical initial step ensures that the selected footwear provides the necessary protection against potential injuries, preventing harm and ensuring compliance with safety standards.

Choosing the right safety footwear is not a one-size-fits-all decision; it fundamentally depends on a meticulous assessment of the specific risks and conditions of the workplace to ensure adequate protection.

Understanding Your Work Environment

Selecting appropriate safety footwear begins with a comprehensive understanding of where and how the work is performed. Ignoring this step can lead to inadequate protection and increased injury risk.

Identify Specific Hazards

Workers should learn about the particular dangers they will encounter. This includes potential impacts from falling objects, compression risks, and sharp object punctures. Identify if there's a risk of cuts or crushing.

Evaluate Environmental Conditions

Assess the physical environment where work takes place. This involves considering if surfaces are wet, oily, or slippery, requiring enhanced traction. Determine if extreme temperatures, either hot or cold, will be a factor.

Matching Footwear to Risk

Once hazards are identified, the next step involves matching the protective features of footwear to those specific risks. This ensures optimal safety for the wearer.

Consider Material Properties

Evaluate the materials used in the footwear, especially the toe cap. Materials like steel, composite, or aluminum offer different levels of impact and compression protection. Ensure they are effective against identified hazards.

Assess Resistance Needs

Determine if specialized resistance is required. This could include resistance to water, heat, cold, or electrical hazards. Puncture and cut resistance are also vital for environments with sharp debris.

Understanding the Trade-offs

While selecting the most protective footwear is essential, it's also important to consider the practical implications and potential drawbacks of different features.

Weight vs. Protection

Heavier materials like steel toes offer robust protection but can increase fatigue over long shifts. Lighter composite options provide protection with reduced weight, but their impact resistance might differ.

Comfort vs. Durability

Highly durable footwear might sometimes be less flexible or comfortable initially. Finding a balance is crucial for worker acceptance and consistent use.

Cost vs. Specialized Features

Footwear with advanced features like electrical hazard protection or extreme temperature resistance can be more expensive. Assess if these specialized features are genuinely necessary for the specific work environment to justify the investment.

Making the Right Choice for Your Goal

The ultimate goal is to select safety footwear that provides maximum protection without compromising worker comfort or operational efficiency.

- If your primary focus is comprehensive hazard protection: Prioritize a thorough hazard assessment to ensure all potential risks, from impacts to electrical dangers, are covered by the footwear's features.

- If your primary focus is worker comfort and acceptance: Balance necessary protective features with lightweight materials and ergonomic designs, ensuring workers will wear the footwear consistently.

- If your primary focus is compliance with regulations: Ensure the chosen footwear meets all industry-specific safety standards and certifications relevant to your workplace's identified hazards.

A proactive and informed approach to safety footwear selection is paramount for protecting workers and fostering a secure work environment.

Summary Table:

| Key Consideration | Why It Matters |

|---|---|

| Identify Hazards | Pinpoint risks like impacts, punctures, or slips to determine required protection. |

| Evaluate Environment | Assess conditions like wet floors or extreme temperatures for material suitability. |

| Match Features to Risks | Ensure footwear properties (e.g., toe cap material, sole grip) align with identified dangers. |

| Consider Trade-offs | Balance protection with factors like weight, comfort, and cost for long-term wearability. |

Ensure your workforce is equipped with the right safety footwear. As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety boots and shoes for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of protective footwear designed to meet specific hazard requirements, ensuring both safety and comfort. Contact us today for a consultation and let us help you protect your most valuable asset—your people.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Premium Suede Metatarsal Guard Safety Boots Work Shoes

People Also Ask

- What is the primary function of specialized protective footwear within the configuration of Level 3 PPE? Expert Insights

- How is compression resistance measured in safety boots? Ensure Maximum Toe Protection on the Job

- Why is the assessment of comfort and fit in occupational protective footwear critical for preventing skin diseases?

- Why are composite toes popular in safety-toe boots? Achieve Superior Comfort & Protection

- How are physical ergonomics research findings applied to protective products? Engineering High-Performance Safety Gear

- Why is footwear critical in bridge vibration models? Enhance Accuracy with Safety Shoes and Tactical Boots Data

- What are the three main construction methods used in safety shoes manufacturing? A Guide to Durability, Water Resistance, and Comfort

- What are the pros and cons of alloy safety toes? Achieve Lighter, Stronger Protection for Your Workforce