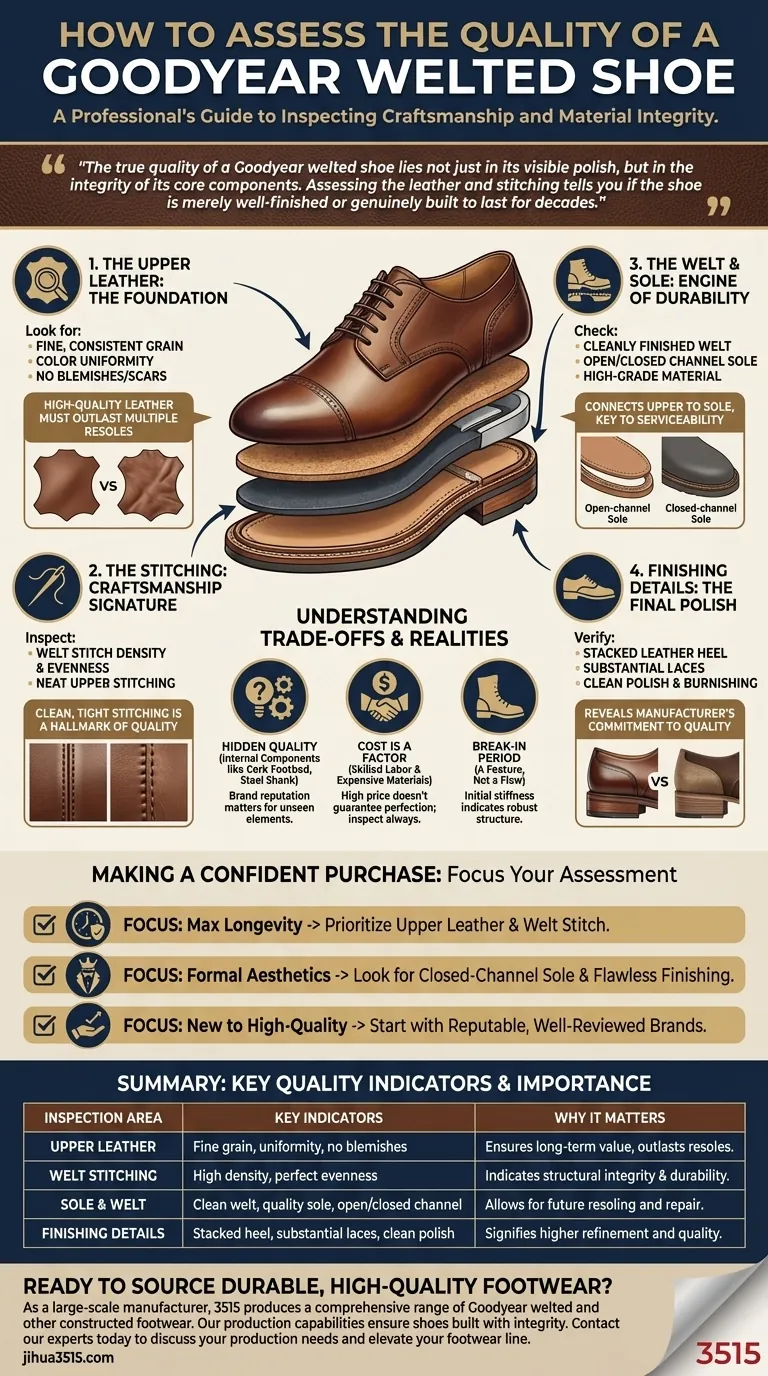

To properly assess the quality of a Goodyear welted shoe, you must look beyond the brand and inspect four key areas: the upper leather for uniformity and blemishes, the density and evenness of the welt stitching, the material and finish of the sole, and the overall cleanliness of the construction. These elements, taken together, provide a clear picture of the craftsmanship and material integrity of the shoe.

The true quality of a Goodyear welted shoe lies not just in its visible polish, but in the integrity of its core components. Assessing the leather and stitching tells you if the shoe is merely well-finished or genuinely built to last for decades.

The Anatomy of Quality: A Point-by-Point Inspection

A Goodyear welt is a complex, labor-intensive construction method designed for longevity. Understanding what to look for allows you to verify that you are getting the durability you are paying for.

The Upper Leather: The Shoe's Foundation

The upper is the single most important material component. Because a Goodyear welted shoe can be resoled multiple times, the leather must be high-quality enough to outlast the original sole.

Look for a fine, consistent grain across the entire shoe. Check for color uniformity and a lack of significant blemishes, scars, or deep wrinkles, which can indicate lower-grade leather.

The Stitching: A Signature of Craftsmanship

The stitching is the most direct signal of the shoemaker's skill. There are two primary areas to inspect.

First, examine the stitching on the upper, which should be neat, straight, and consistent. More importantly, inspect the welt stitch, the thread that joins the welt to the sole. Look for a high stitch density and perfect evenness. Clean, tight stitching here is a hallmark of quality.

The Welt and Sole: The Engine of Durability

The welt itself—the strip of leather running along the perimeter of the sole—should be cleanly finished. It connects the upper to the sole and is the key to the shoe's serviceability.

Inspect the sole's material, which is typically leather or high-grade rubber. Also, check how the stitch is finished. An open-channel sole has a visible groove with the stitching exposed, making it easy to inspect. A closed-channel sole, where a flap of leather is cut, stitched, and then glued back down to hide the thread, is a sign of higher-end finishing and aesthetics.

Finishing Details: The Final Polish

Small details often reveal the manufacturer's overall commitment to quality.

Check the heel stack, which should be made of stacked layers of leather, not a block of fiberboard wrapped in a veneer. The laces should feel substantial, and the overall polish and burnishing should be clean and artfully applied.

Understanding the Trade-offs and Realities

While the inspection points are critical, a complete assessment requires understanding the inherent characteristics and common pitfalls associated with this construction.

Hidden Quality vs. Visible Finish

You cannot see some of the most important components, such as the cork footbed that molds to your foot or the steel shank that provides support. This is where brand reputation becomes a practical factor, as established makers are trusted to use high-quality internal components.

Cost is a Factor, But Not the Only One

The high cost of these shoes reflects the expensive materials and the significant amount of skilled labor required. However, a high price tag does not automatically guarantee flawless execution. Always perform your own inspection.

The Break-in Period Is a Feature, Not a Flaw

A key trade-off for the extreme durability of a Goodyear welt is stiffness. The robust internal structure, including the cork bed and sturdy insole, requires a break-in period to mold to your foot. This initial discomfort is a sign of the shoe's resilient build.

Making a Confident Purchase

Your final decision should align with your primary goal for the footwear. Use these guidelines to focus your assessment.

- If your primary focus is maximum longevity: Prioritize the quality of the upper leather and the neatness of the welt stitch, as these are the core components that allow for multiple resoles.

- If your primary focus is formal aesthetics: Look for closed-channel soles, flawless finishing on the upper, and a cleanly executed heel stack, as these details signify a higher level of refinement.

- If you are new to high-quality footwear: Start with a reputable, well-reviewed brand known for Goodyear welts to ensure you are getting a product with proven construction and reliable materials.

By learning to read these signs of quality, you transform a simple purchase into a long-term investment in durability and style.

Summary Table:

| Inspection Area | Key Quality Indicators | Why It Matters |

|---|---|---|

| Upper Leather | Fine, consistent grain; color uniformity; no blemishes | High-quality leather must outlast multiple resoles, ensuring long-term value. |

| Welt Stitching | High stitch density; perfect evenness; clean and tight | A signature of craftsmanship, indicating the shoe's structural integrity and durability. |

| Sole & Welt | Cleanly finished welt; quality leather/rubber sole; open or closed channel | The engine of durability; proper construction allows for future resoling and repair. |

| Finishing Details | Stacked leather heel; substantial laces; clean polish and burnishing | Reveals the manufacturer's overall commitment to quality and refinement. |

Ready to Source Durable, High-Quality Footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of Goodyear welted and other constructed footwear for distributors, brand owners, and bulk clients. Our production capabilities ensure you receive shoes built with integrity—from premium upper leathers to precise welt stitching—guaranteeing the longevity and style your customers demand.

Contact our experts today to discuss your production needs and elevate your footwear line.

Visual Guide

Related Products

- Wholesale Comfortable Business Casual Shoes Custom Manufacturing

- Custom Manufactured Air Cushion Leather Business Shoes for Wholesale

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Durable & Breathable Training Shoes for Custom Brands

- Factory Direct Wholesale Leather Comfort Shoes with Dial Closure

People Also Ask

- What are the key considerations when choosing dress shoes for formal occasions? A Guide to Style, Color & Quality

- What shoes are acceptable for business casual? A Guide to Polished & Professional Footwear

- What types of dress shoes are recommended for formal occasions? A Guide to Impeccable Style

- Is it acceptable to wear dress shoes with casual outfits? Elevate Your Smart Casual Office Style

- How can one balance a casual outfit when wearing dress shoes? Achieve a Polished Smart Casual Look