First, I need to understand what they really want. It's not just "dry shoes," it's "how do I dry them without screwing them up?" That's the "deep need" I'm addressing. They want to prevent damage, extend the life of their expensive work shoes, and have them ready to go when they need them.

I'm thinking, this needs to be super clear and actionable. I'll use a specific structure: bolded hook, a key takeaway upfront, clear sections (H2s and H3s) addressing the "why" behind each step, and a final section with actionable bullet points. The format will make it easy to digest, with a strong focus on trade-offs and pitfalls, so the user can easily determine the "why" behind the instructions.

I've got the research, which boils down to a few core principles. Remove insoles and laces, stuff with newspaper, and let them dry naturally, away from heat. Easy, right? But the references also have crucial details: wipe excess moisture, avoid using heat, and condition the leather after drying. They also point to proactive care with waterproofing.

My plan: I'll start by making the point that quick action is critical and that direct heat is the enemy. Then, I'll detail the step-by-step process of drying, explaining the reasoning behind each action. Why remove the laces and insoles? Circulation. Why newspaper? It absorbs moisture. Then, I'll hit them with the "Pitfalls to Avoid." Heat is bad. Improper storage is worse. Skipping the conditioning? Forget about it.

Finally, I'll loop back to the real solution. Waterproofing and having a backup pair are preventative measures and they should be encouraged as a long-term strategy for anyone working in a wet environment.

I'll end with a clear set of choices: Immediate need? Here's the most efficient process for the fastest dry. Shoe preservation? Don't skip conditioning. Frequent wet weather? Look into waterproofing and a shoe rotation. And the overall goal is to give them the tools to turn a potential problem into a simple, manageable routine. This will make me a trusted technical advisor. When your work shoes get soaked in the rain, your immediate goal is to remove the moisture safely. To do this, take out the insoles and laces to expose all surfaces. Wipe away any excess water and then stuff the shoes tightly with newspaper, which will absorb internal moisture without using damaging heat.

The core principle is not simply to dry your shoes, but to do so slowly and naturally. Rushing the process with a direct heat source is the most common and costly mistake, as it can permanently warp and crack the materials.

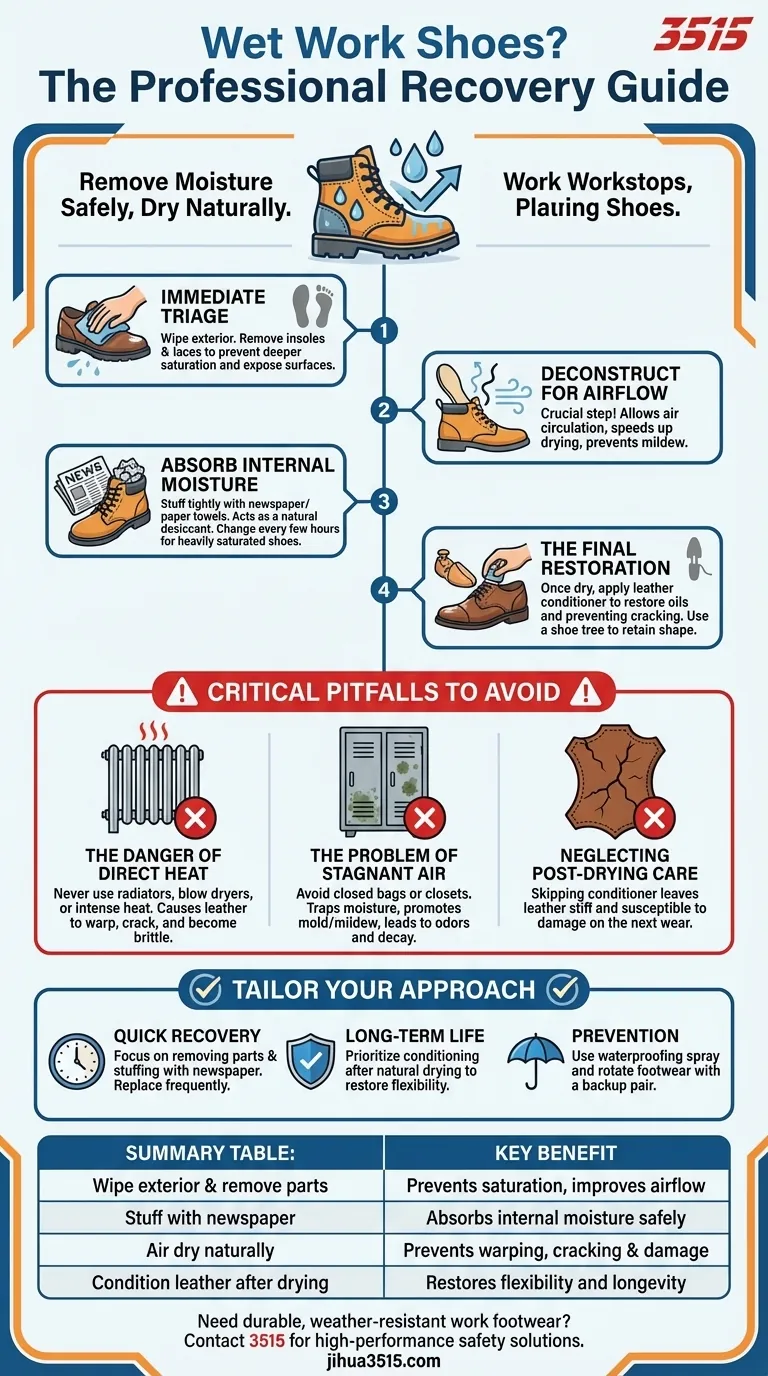

The Step-by-Step Recovery Process

Properly drying your footwear is a process of triage and restoration. Each step is designed to preserve the shoe's integrity, especially for materials like leather that are vulnerable when wet.

Step 1: Immediate Triage

As soon as you take them off, wipe down the entire exterior of the shoes with a clean, dry rag. This removes surface water and prevents it from soaking deeper into the material.

Step 2: Deconstruct for Airflow

Remove the insoles and the laces completely. This is a critical step that allows air to circulate freely into every part of the shoe, dramatically speeding up the drying time and preventing mildew.

Step 3: Absorb Internal Moisture

Stuff the shoes tightly with crumpled newspaper or paper towels. These materials act as a natural desiccant, wicking moisture out from the inside. For heavily saturated shoes, you may need to replace the newspaper every few hours.

Step 4: The Final Restoration

Once the shoes are completely dry to the touch, it's time to restore them. If they are leather, apply a quality conditioner to replenish the oils lost during the drying process. Re-inserting a cedar shoe tree at this stage will help the shoe retain its proper shape.

Critical Pitfalls to Avoid

What you don't do is just as important as what you do. Avoiding these common mistakes will prevent irreversible damage and extend the life of your work shoes.

The Danger of Direct Heat

Never place wet shoes near a direct heat source like a radiator, furnace vent, or fireplace. Do not use a blow dryer. Intense heat dries the material, particularly leather, too quickly, causing it to become brittle and crack.

The Problem of Stagnant Air

Do not leave soaked shoes in a closed locker, a gym bag, or a poorly ventilated closet. This traps moisture and creates a perfect environment for mold, mildew, and bacteria to grow, leading to permanent odors and material decay.

Neglecting Post-Drying Care

Simply drying the shoe isn't enough. Leather that has been soaked and then dried is stripped of its natural oils. Skipping the conditioning step leaves it stiff and highly susceptible to cracking with the next wear.

Making the Right Choice for Your Situation

Your approach can be tailored to your primary goal, whether it's a quick turnaround or maximizing the lifespan of your investment.

- If your primary focus is immediate recovery: Concentrate on removing the insoles and stuffing the shoes with newspaper, replacing it every 3-4 hours to ensure the fastest possible natural drying time.

- If your primary focus is long-term shoe life: The most crucial step is applying a quality leather conditioner after the shoes are completely dry to restore flexibility and prevent cracking.

- If your primary focus is prevention: Proactively treat your shoes with a waterproofing spray and strongly consider owning a second pair to rotate, ensuring one pair can always dry fully for 24-48 hours.

Proper care transforms a wet-day problem into a simple, manageable routine.

Summary Table:

| Step | Action | Key Benefit |

|---|---|---|

| 1 | Wipe exterior & remove insoles/laces | Prevents deeper saturation, improves airflow |

| 2 | Stuff tightly with newspaper | Absorbs internal moisture safely |

| 3 | Air dry naturally away from heat | Prevents warping, cracking, and material damage |

| 4 | Condition leather after drying | Restores flexibility and longevity |

Need durable, weather-resistant work footwear that stands up to the elements? As a large-scale manufacturer, 3515 produces a comprehensive range of high-performance safety shoes and boots for distributors, brand owners, and bulk clients. Our expertise ensures your team has reliable footwear designed for comfort and long-term wear. Contact us today to discuss your specific needs and discover how we can support your business with quality footwear solutions.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium Wholesale Tactical Style Safety Shoes Boots with Quick Lacing

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

People Also Ask

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- Can heavy duty work boots be worn daily outside of work? Discover Durable, All-Day Comfort

- What materials are used for safety toes? Choose Steel, Composite, or Aluminum for Your Work Boots

- What type of footwear is required in meatpacking and poultry plants due to slippery conditions? Essential Safety Boots for Slippery Floors

- What are the primary protective functions of composite-toe boots? A Guide to Modern Safety Footwear