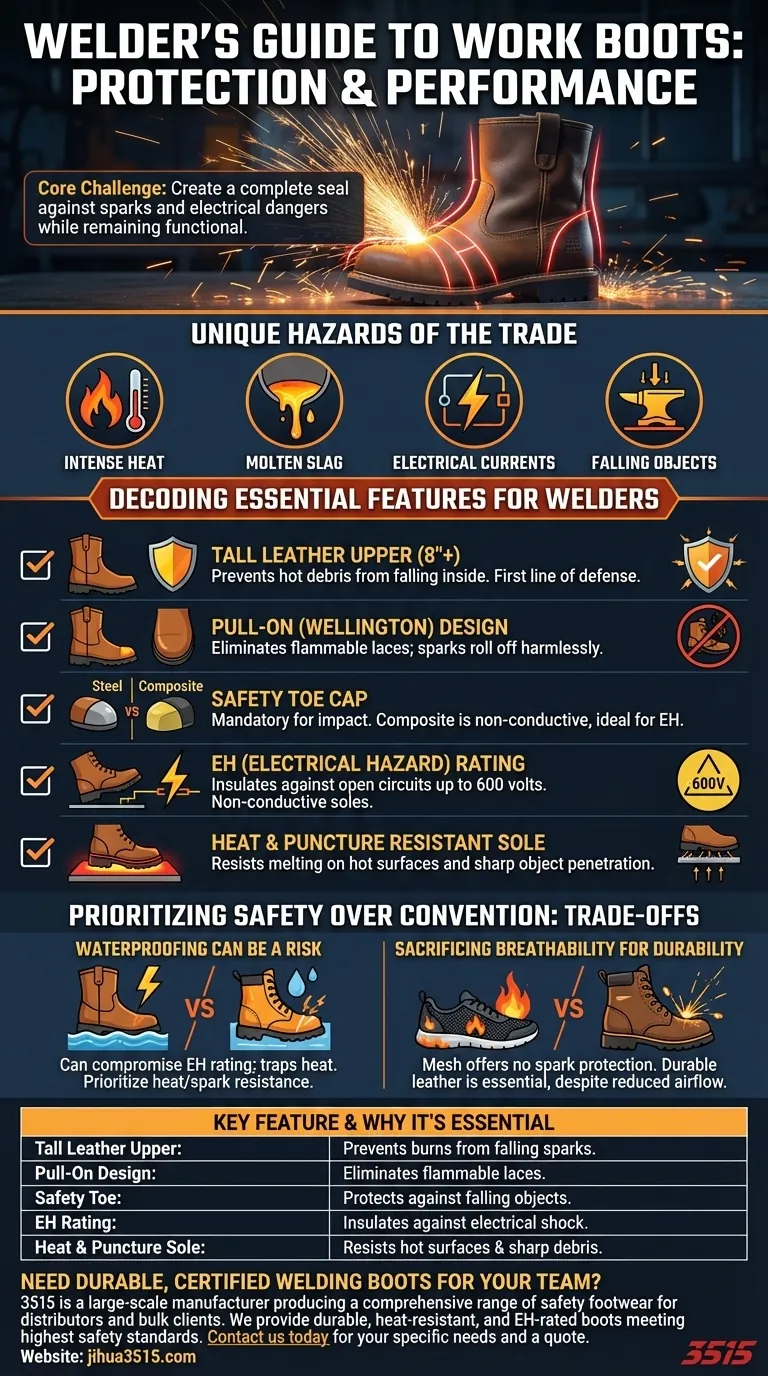

When selecting work boots, welders must prioritize features that protect against the unique hazards of their trade: intense heat, molten slag, electrical currents, and falling objects. The ideal boot combines a high, heat-resistant leather upper with a safety toe, pull-on design, and an Electrical Hazard (EH) rating to provide comprehensive protection.

The core challenge for a welder isn't just finding a durable boot, but finding one that creates a complete seal against high-velocity sparks and electrical dangers while remaining functional for a full day's work.

Decoding the Essential Features for Welders

A standard work boot is not sufficient for welding. The constant shower of sparks and potential for electrical contact demand a specialized set of non-negotiable safety features.

Protection from the Top Down

The most immediate threat to a welder's feet comes from above in the form of sparks, slag, and embers.

The boot's upper portion is the first line of defense. A tall leather upper, ideally 8 inches or more, creates a crucial barrier that prevents hot debris from falling inside the boot and causing severe burns.

The Problem with Laces

Traditional laced boots present a significant vulnerability for welders. The laces can easily catch and be destroyed by sparks and slag.

A pull-on (Wellington) style boot eliminates this risk entirely. This laceless design presents a smooth, uninterrupted surface that allows sparks to roll off harmlessly, enhancing both safety and the boot's lifespan.

Shielding Against Impact and Compression

Welders work with heavy metal pieces, tools, and equipment, making foot protection from falling objects essential.

A safety toe cap is mandatory. While steel toes offer maximum protection, composite toes are lighter and do not conduct heat or electricity, making them an excellent choice for welders who also require an EH rating.

Understanding the Critical Safety Ratings

Beyond the physical construction, certified safety ratings ensure the boot is tested to withstand specific workplace hazards. For welders, two ratings are paramount.

The Electrical Hazard (EH) Rating

Welders frequently work around live electrical circuits, creating a risk of electrocution.

An EH-rated boot is constructed with non-conductive, shock-resistant soles and heels. This feature is designed to protect the wearer from open circuits of up to 600 volts in dry conditions, providing a critical layer of insulation.

Heat and Puncture Resistance

The soles of the boots are in direct contact with hot surfaces and potentially sharp metal scraps on the shop floor.

A heat-resistant outsole, often made from rubber or nitrile, prevents the sole from melting when stepping on hot metal. Additionally, a puncture-resistant plate can protect against sharp objects piercing through the bottom of the boot.

The Trade-offs: Prioritizing Safety Over Convention

Choosing the right welding boot means accepting that features common in other work boots can become liabilities in a welding environment.

Why Waterproofing Can Be a Risk

Many work boots feature waterproof membranes. However, for a welder, this can be a double-edged sword. While it keeps water out, it can also trap sweat and heat, leading to discomfort.

More importantly, a boot fully submerged in water can compromise its EH rating, as water is an excellent electrical conductor. For most welding applications, heat and spark resistance are far more critical than waterproofing.

Sacrificing Breathability for Durability

Materials like mesh or canvas that offer high breathability have no place in a welding boot. They provide zero protection against sparks and slag.

Welders must choose durable, thick leather over more breathable materials. While this reduces airflow, it is an essential trade-off for preventing serious burns.

Making the Right Choice for Your Work

Your specific welding environment and tasks should guide your final selection. Use these points as a checklist.

- If your primary focus is maximum protection in a heavy fabrication shop: Prioritize a pull-on design with a steel toe, an 8-inch or higher leather upper, and a metatarsal guard for added top-of-foot protection.

- If you work around live circuits or in maintenance roles: An EH-rated, composite-toe boot is essential to protect against electrical shock without sacrificing impact resistance.

- If you need a versatile boot for both welding and other tasks: Look for a hybrid that meets all core welding safety needs (leather, safety toe, EH rating) but offers slightly more comfort and flexibility, potentially with a 6-inch upper if your spark exposure is minimal.

Ultimately, selecting the right welding boot is a critical investment in your personal safety and daily comfort on the job.

Summary Table:

| Key Feature | Why It's Essential for Welders |

|---|---|

| Tall Leather Upper (8+ inches) | Prevents hot sparks and slag from falling into the boot, preventing burns. |

| Pull-On (Wellington) Design | Eliminates flammable laces; allows sparks to roll off harmlessly. |

| Safety Toe Cap (Steel/Composite) | Protects feet from heavy falling objects and equipment. |

| EH (Electrical Hazard) Rating | Provides insulation against open electrical circuits up to 600 volts. |

| Heat & Puncture Resistant Sole | Protects against hot surfaces and sharp metal debris on the floor. |

Need Durable, Certified Welding Boots for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of specialized shoes and boots, including welding boots that meet the highest safety standards.

We can provide the durable, heat-resistant, and EH-rated footwear your customers rely on. Contact us today to discuss your specific needs and get a quote.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- How do industrial safety shoes provide protection for personnel? Safeguard Your Team from Heavy Crane Hazards

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- Why can metal protective toecaps become a risk factor for dorsal foot ulcers? Learn to Prevent Pressure Point Injuries