Breaking in new tall boots is a notorious rite of passage for every equestrian. You should expect significant stiffness, pressure points, and notable discomfort, particularly behind the knee. This challenging phase is temporary and necessary for the rigid leather to soften and mold perfectly to the unique shape of your leg, eventually resulting in a custom-like fit.

The initial pain of breaking in tall boots isn't a sign of a poor fit; it's a necessary process of the leather conforming to your body. The goal isn't to avoid this process, but to manage it effectively to accelerate comfort and prevent sores.

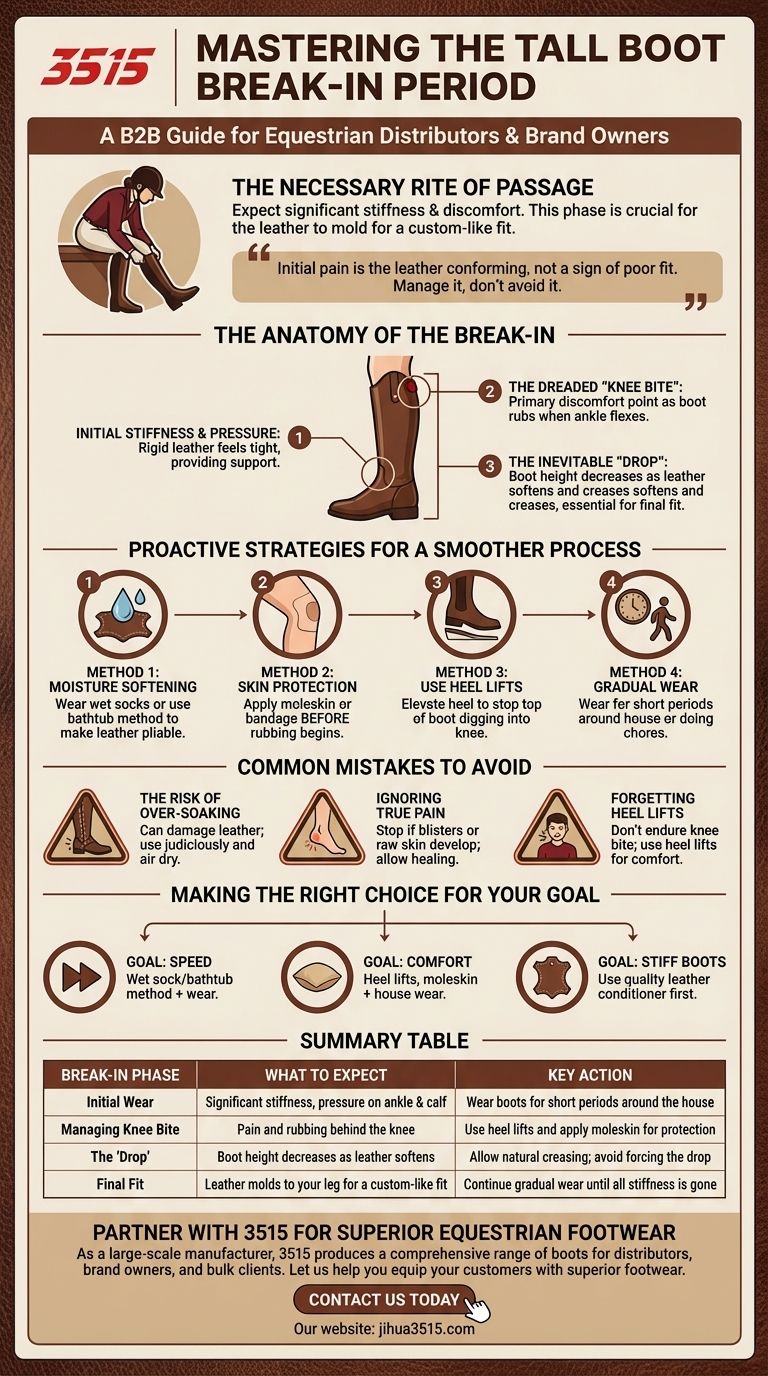

The Anatomy of the Break-In Period

Before you can solve the problem, you need to understand what's happening. A new boot is a stiff, unyielding cylinder that must learn to bend and crease in all the right places.

Initial Stiffness and Pressure

New riding boots, especially high-quality ones, are made from rigid leather. Expect them to feel tight and inflexible, particularly around the ankle and calf. This stiffness is a feature, not a flaw, as it provides the necessary support for riding.

The Dreaded "Knee Bite"

The most common and painful complaint is rubbing or pinching behind the knee. As you flex your ankle to sink your heel down, the top of the boot digs into the back of your knee. This is the primary source of discomfort that needs to be managed.

The Inevitable "Drop"

Tall boots are designed to be too tall at first. As the leather softens and creases around your ankle, the overall height of the boot will "drop" by an inch or more. This process is essential for achieving the correct final height and fit.

Proactive Strategies for a Smoother Process

You can actively manage the break-in period to minimize pain and speed up the process. These techniques focus on softening the leather and protecting your skin.

Method 1: Softening the Leather with Moisture

Moisture makes leather more pliable, allowing it to stretch and mold to your leg faster.

The most aggressive version is the "bathtub method," where you get the boots thoroughly wet and then wear them until they are dry. A gentler approach is to wear wet socks inside your new boots, allowing the moisture to soften the leather from the inside out.

Method 2: Protecting Your Skin

Preventing blisters and raw skin is critical. Apply moleskin or a thick bandage to the back of your knees before you even feel rubbing. This creates a simple but effective barrier.

Method 3: Using Heel Lifts

This is the single most effective tool for preventing knee bite. By placing heel lifts or risers inside your boots, you elevate your heel. This small change provides just enough clearance to stop the top of the boot from digging into the back of your knee while the ankle drops.

Method 4: Gradual, Low-Impact Wear

Don't make your first ride the first time you wear your new boots. Wear them around the house or while doing barn chores for a few hours at a time. This allows the leather to begin molding to your leg from simple walking before you add the stress of the riding position.

Understanding the Trade-offs and Common Mistakes

Choosing the right approach requires understanding the potential downsides. Rushing the process can be counterproductive.

The Risk of Over-Soaking

While effective, fully soaking your boots can potentially damage certain types of leather or stitching if done improperly or too frequently. Use moisture methods judiciously and always allow boots to air dry naturally, away from direct heat.

Ignoring True Pain

There is a significant difference between discomfort and genuine pain that causes skin damage. If you develop blisters or raw, broken skin, stop. Allow your leg to heal completely before trying again, and use more protective measures like moleskin.

Forgetting the Heel Lifts

Many riders try to endure the knee bite without assistance. Heel lifts are an inexpensive and temporary tool that makes the entire process dramatically more comfortable. Removing them too soon is as much a mistake as not using them at all.

Making the Right Choice for Your Goal

Your approach should match your tolerance for discomfort and your timeline.

- If your primary focus is speed: The wet sock or bathtub method combined with wearing the boots is the fastest way to force the leather to conform.

- If your primary focus is comfort: Start by using heel lifts and moleskin, and wear the boots around the house for several days before attempting short rides.

- If your boots are exceptionally stiff: Use a quality leather conditioner to help soften the material before you even begin wearing them for the first time.

Patience through this initial phase is the investment you make for years of comfort, support, and performance from your boots.

Summary Table:

| Break-In Phase | What to Expect | Key Action |

|---|---|---|

| Initial Wear | Significant stiffness, pressure on ankle and calf | Wear boots for short periods around the house |

| Managing Knee Bite | Pain and rubbing behind the knee | Use heel lifts and apply moleskin for protection |

| The 'Drop' | Boot height decreases as leather softens | Allow natural creasing; avoid forcing the drop |

| Final Fit | Leather molds to your leg for a custom-like fit | Continue gradual wear until all stiffness is gone |

Ready for Boots That Combine Quality with a Smoother Break-In?

As a large-scale manufacturer, 3515 produces a comprehensive range of equestrian and work footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of boots, designed with both performance and wearer comfort in mind.

Let us help you equip your customers with superior footwear.

Contact us today to discuss your boot manufacturing needs and discover how we can deliver quality and value for your business.

Visual Guide

Related Products

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

- Wholesale Classic Leather Lace-Up Ankle Boots for Brand Manufacturing

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- What type of leather conditioner and polish is recommended? A Guide to Proper Nourishment & Protection

- What is the role of high-speed electric motors in shoe polishing machines? Boosting Production Speed & Finish Quality

- How is the Visual Analog Scale (VAS) utilized in functional footwear R&D? Optimize Comfort through Human-Centric Data

- What is the role of ergonomic workbenches in footwear pattern design? Boost Precision and Protect Artisan Health

- What makes patent leather distinctive for shoes? Its High-Gloss, Low-Maintenance Appeal

- Why is EVA used with carbon fiber plates in footwear? Balancing Rigidity and Comfort for Peak Performance

- Why is a high-performance microcontroller control board required for processing gait signals? Lower Latency Secrets

- What are vegan leather alternatives for shoes? Choose the Right Material for Your Needs