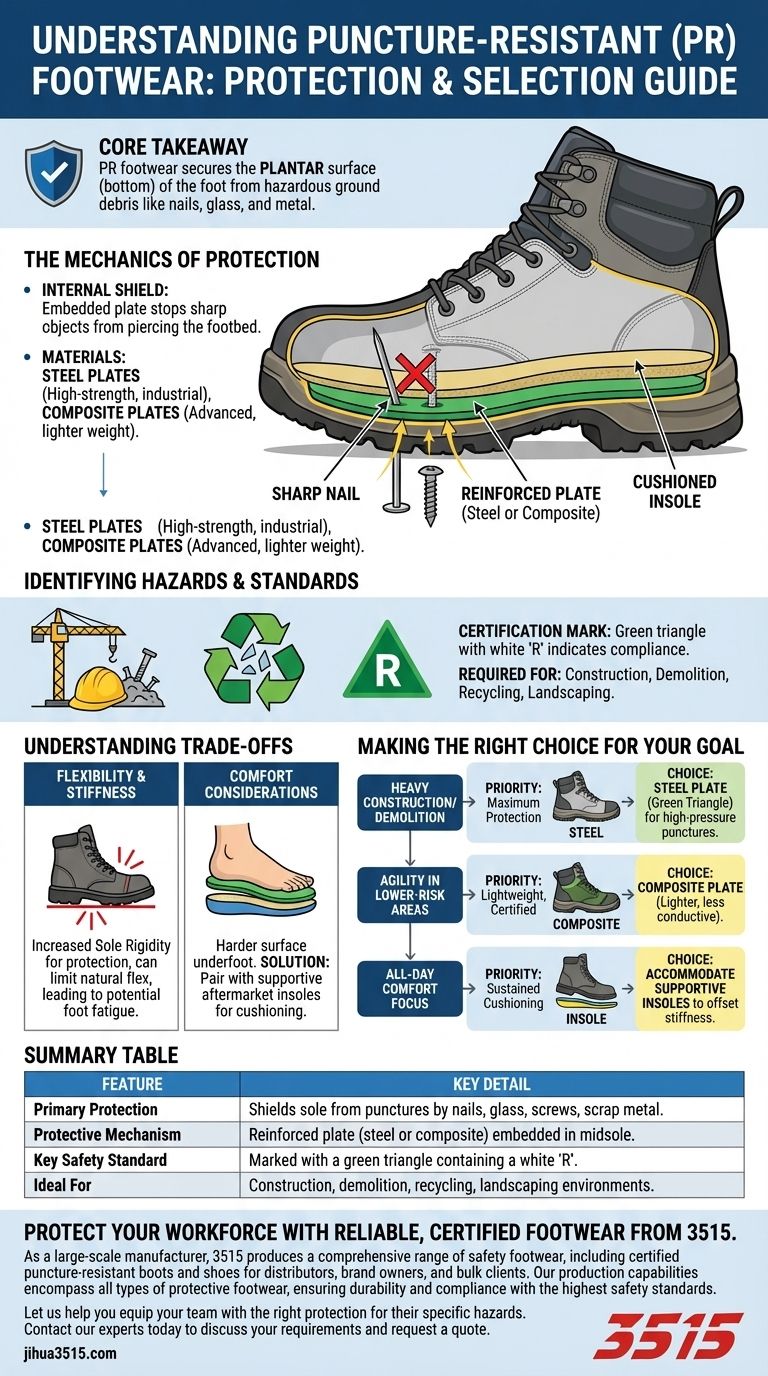

Puncture-resistant (PR) footwear is designed to create an impenetrable barrier between the sole of your foot and hazardous ground debris. These boots utilize a reinforced plate—typically made of steel or a durable composite material—embedded within the midsole to stop sharp objects like nails, glass shards, screws, and scrap metal from piercing through the shoe. To ensure compliance with safety standards, legitimate PR footwear is clearly marked, most commonly with a green triangle containing a white 'R'.

Core Takeaway While standard safety boots often prioritize toe protection, puncture-resistant footwear specifically secures the plantar surface (bottom) of the foot. By integrating a protective plate between the insole and outsole, these boots mitigate the risk of debilitating puncture wounds in unpredictable environments like construction sites and demolition zones.

The Mechanics of Protection

The Internal Shield

The primary defense mechanism in PR footwear is not merely the thickness of the rubber sole. It is a dedicated protective plate positioned between the insole and the outsole.

This internal layer acts as a shield. It engages the moment you step on a sharp object, distributing the force and preventing penetration into the footbed.

Material Composition

Manufacturers achieve this resistance using two main materials: steel or composites.

Steel plates offer traditional, high-strength protection and are often found in heavy-duty industrial boots. Composite plates use advanced synthetic materials to provide similar resistance, often with less weight.

Identifying Hazards and Standards

Environments Requiring PR Gear

Puncture risks are highest where debris is uncontrolled or hidden.

Construction and demolition sites are the most common use cases, where stray nails and screws are ubiquitous. Recycling centers and landscaping environments also pose significant risks from glass shards and scrap metal.

Visual Verification

You generally cannot determine if a boot is puncture-resistant just by looking at the tread. You must look for the certification label.

In many jurisdictions, this is indicated by a green triangle on the boot, which houses a white letter 'R'. This symbol guarantees the footwear has met specific testing standards for reducing injury risks from sharp hazards.

Understanding the Trade-offs

Flexibility and Stiffness

Because PR boots contain a reinforced plate, the sole is naturally more rigid than a standard work boot.

This rigidity is necessary to stop a nail, but it can limit the natural flex of your foot while walking. This may lead to foot fatigue during long shifts if you are walking significant distances.

Comfort Considerations

The internal plate changes the feel of the footbed. It creates a harder surface underfoot compared to a standard foam midsole.

To counteract this, it is often recommended to pair PR boots with supportive aftermarket insoles. This restores cushioning without compromising the safety function of the puncture plate.

Making the Right Choice for Your Goal

Selecting the right footwear depends on balancing the severity of the hazard with your daily mobility requirements.

- If your primary focus is heavy construction or demolition: Prioritize boots with a steel plate and the green triangle symbol to ensure maximum protection against high-pressure punctures like upturned nails.

- If your primary focus is agility in lower-risk areas: Consider boots with composite plates, which offer certified protection but may be lighter and slightly less conductive to temperature than steel.

- If your primary focus is all-day comfort: Ensure you size your boots to accommodate high-quality, supportive insoles to offset the stiffness of the protective plate.

True safety comes from understanding that the sole of your boot is your only shield against the unseen hazards beneath you.

Summary Table:

| Feature | Key Detail |

|---|---|

| Primary Protection | Shields the sole from punctures by nails, glass, screws, and scrap metal. |

| Protective Mechanism | A reinforced plate (steel or composite) embedded in the midsole. |

| Key Safety Standard | Marked with a green triangle containing a white 'R'. |

| Ideal For | Construction, demolition, recycling, and landscaping environments. |

Protect your workforce with reliable, certified footwear from 3515.

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear, including certified puncture-resistant boots and shoes for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of protective footwear, ensuring durability and compliance with the highest safety standards.

Let us help you equip your team with the right protection for their specific hazards. Contact our experts today to discuss your requirements and request a quote.

Visual Guide

Related Products

- Wholesale Slip-On Safety Boots Manufacturer - Custom Puncture-Proof & Steel Toe

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium Grain Leather Safety Boots for Bulk Supply

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

People Also Ask

- How does a Reliability Block Diagram (RBD) enhance footwear stability? Engineering High-Performance Shoe Systems

- What is dielectric insulation in safety footwear used for? Essential Protection for High-Voltage Work

- What is the primary function of a cooling system in safety shoe production? Ensure Structural Integrity and Speed

- What protective roles do industrial-grade safety shoes serve in the casting station? Safety in Foundry Environments

- Why is slip resistance an important factor in safety footwear? Prevent Slips and Falls in the Workplace

- How is the AMEDA utilized in footwear R&D? Optimize Safety Shoes and Training Boots for Superior Ankle Stability

- What are the risks of wearing the wrong safety toe boot? Avoid Catastrophic Injury & Chronic Pain

- What is the clinical preventive significance of professional protective footwear for APS? Lower Necrosis Risks Now