To properly waterproof your boots, you must first work in a well-ventilated area, wear protective gear like gloves if using chemicals, and always test the waterproofing product on a small, hidden part of the boot first. Crucially, you must avoid using direct heat sources like hair dryers to speed up drying, as this can permanently damage the boot's material and adhesives.

The goal of waterproofing is not just to apply a product, but to prepare the boot correctly so it can accept the treatment without being damaged. Your primary precautions should focus on protecting both yourself from fumes and the boot material from discoloration or heat damage.

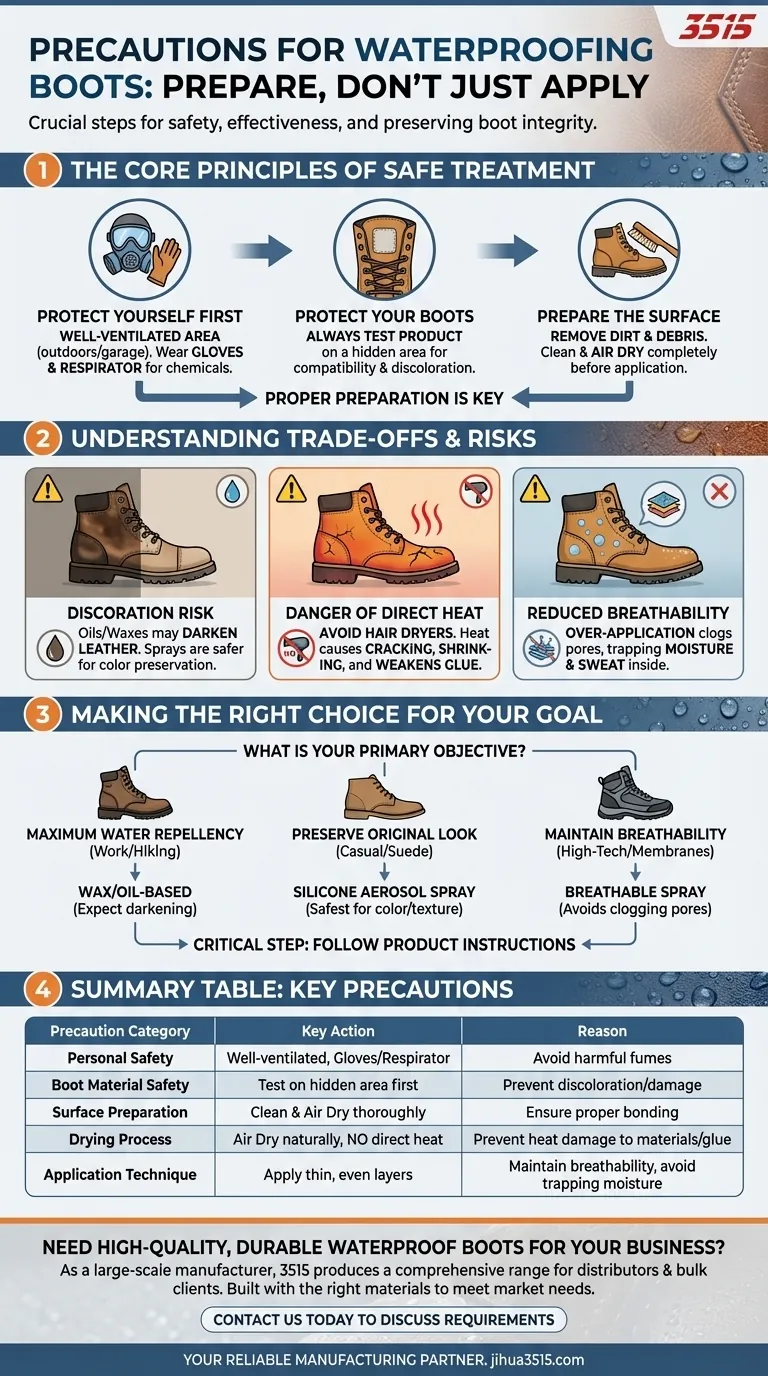

The Core Principles of Safe Boot Treatment

Waterproofing seems simple, but a few missteps can ruin an expensive pair of boots. The process is less about the application itself and more about careful preparation and adherence to the product's specific chemistry.

Protect Yourself First

Your immediate priority is personal safety, especially when using aerosols or strong chemical treatments.

Work in a well-ventilated space, preferably outdoors or in a garage with the door open, to avoid inhaling fumes. For aerosol sprays or potent chemical treatments, consider wearing a basic respirator and protective gloves.

Protect Your Boots from the Product

Not all waterproofing products are compatible with all materials. A treatment designed for full-grain leather could ruin suede or synthetic fabric.

Always test the product on an inconspicuous area first, such as the inner side of the boot's tongue or a low part of the heel. This allows you to check for any unexpected discoloration or texture changes before committing to the entire boot.

Prepare the Surface for Application

Applying a waterproofing agent to a dirty boot is like painting over a dusty wall—it won't stick properly. The treatment needs to bond directly with the boot material.

Start by removing all loose dirt and debris with a brush. Then, clean the boots according to the manufacturer's instructions, often with a simple soap and water solution, and let them air dry completely before proceeding.

Understanding the Key Trade-offs and Risks

Applying waterproofing treatments involves balancing effectiveness with potential risks to your gear. Understanding these trade-offs is key to a successful outcome.

The Risk of Discoloration

Some of the most effective waterproofing agents, like heavy waxes or oil-based treatments, can darken the color of leather. While this is often a desired effect for work boots, it can be an unwelcome change for casual or fashion footwear. Sprays are generally less likely to cause significant color shifts.

The Dangers of Using Heat

It can be tempting to use a hair dryer or place boots near a heater to speed up the drying process. This is the most common and damaging mistake.

Direct heat can cause leather to crack, shrink, or become brittle. It can also weaken the glues and adhesives that bond the sole to the upper, compromising the boot's entire structure. Always let boots air dry naturally at room temperature.

Over-Application Diminishes Breathability

More is not always better. Applying an excessively thick layer of wax or cream can clog the pores in leather and synthetic membranes (like Gore-Tex).

This traps moisture and sweat inside the boot, defeating the purpose of breathable materials and leading to discomfort. Follow the product instructions and apply thin, even layers, allowing each to dry before adding another if necessary.

Making the Right Choice for Your Goal

Your approach should be tailored to the type of boots you own and your primary objective.

- If your primary focus is maximum water repellency for rugged work or hiking boots: A wax or oil-based treatment is often superior, but be prepared for it to slightly darken the leather.

- If your primary focus is preserving the original look of casual leather or suede boots: A silicone-based aerosol spray is the safest choice, as it is less likely to alter color or texture.

- If your primary focus is maintaining the breathability of high-tech hiking boots: Use a spray-on treatment specifically designed for synthetic fabrics and waterproof membranes to avoid clogging the material's pores.

Ultimately, carefully following the instructions on your chosen waterproofing product is the most critical step to protecting your investment.

Summary Table:

| Precaution Category | Key Action | Reason |

|---|---|---|

| Personal Safety | Work in a well-ventilated area; wear gloves/respirator | Avoid inhaling harmful fumes from chemical treatments |

| Boot Material Safety | Test product on a small, hidden area first | Prevent discoloration or damage to incompatible materials |

| Surface Preparation | Clean boots thoroughly and let air dry completely | Ensure proper bonding of the waterproofing agent |

| Drying Process | Air dry naturally at room temperature; avoid direct heat | Prevent cracking, shrinking, or glue damage from heat sources |

| Application Technique | Apply thin, even layers; avoid over-application | Maintain boot breathability and prevent moisture trapping |

Need high-quality, durable waterproof boots for your business?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of waterproof shoes and boots, built with the right materials and construction to meet your specific market needs.

Contact us today to discuss your requirements and learn how we can be your reliable manufacturing partner!

Visual Guide

Related Products

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- High Performance Fire-Retardant Waterproof Safety Boots

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium KPU Injection Athletic Style Safety Shoes

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

People Also Ask

- What protective features do professional Safety Shoes provide in shipyard environments? Maximize Worker Safety

- What are the protective functions of industrial safety boots in sugar factory clarification stations? Thermal & Slip Experts

- What is the function of impact-resistant toe caps in safety footwear? Protect Your Feet During Heavy Lifting

- What are the primary protective functions of industrial-grade safety shoes during heavy machinery maintenance such as ship engine overhauls? Essential Protection for Extreme Environments.

- How do Robotic Gait Systems verify the durability and safety of mass-produced safety boots? Ensure Unrivaled Performance in Extreme Conditions