For maximum durability in tactical boots, prioritize full-grain leather or high-denier ballistic nylon for the uppers, polyurethane (PU) for the midsole, and high-grade vulcanized rubber for the outsole. These materials, combined with strong construction methods like stitched seams, form the foundation of a boot that can withstand demanding use and rough terrain over time.

True boot durability isn't about a single "best" material. It's about understanding how the upper, midsole, and outsole work together as a system to resist wear and absorb impact, while balancing the trade-offs between absolute toughness and other critical factors like weight and agility.

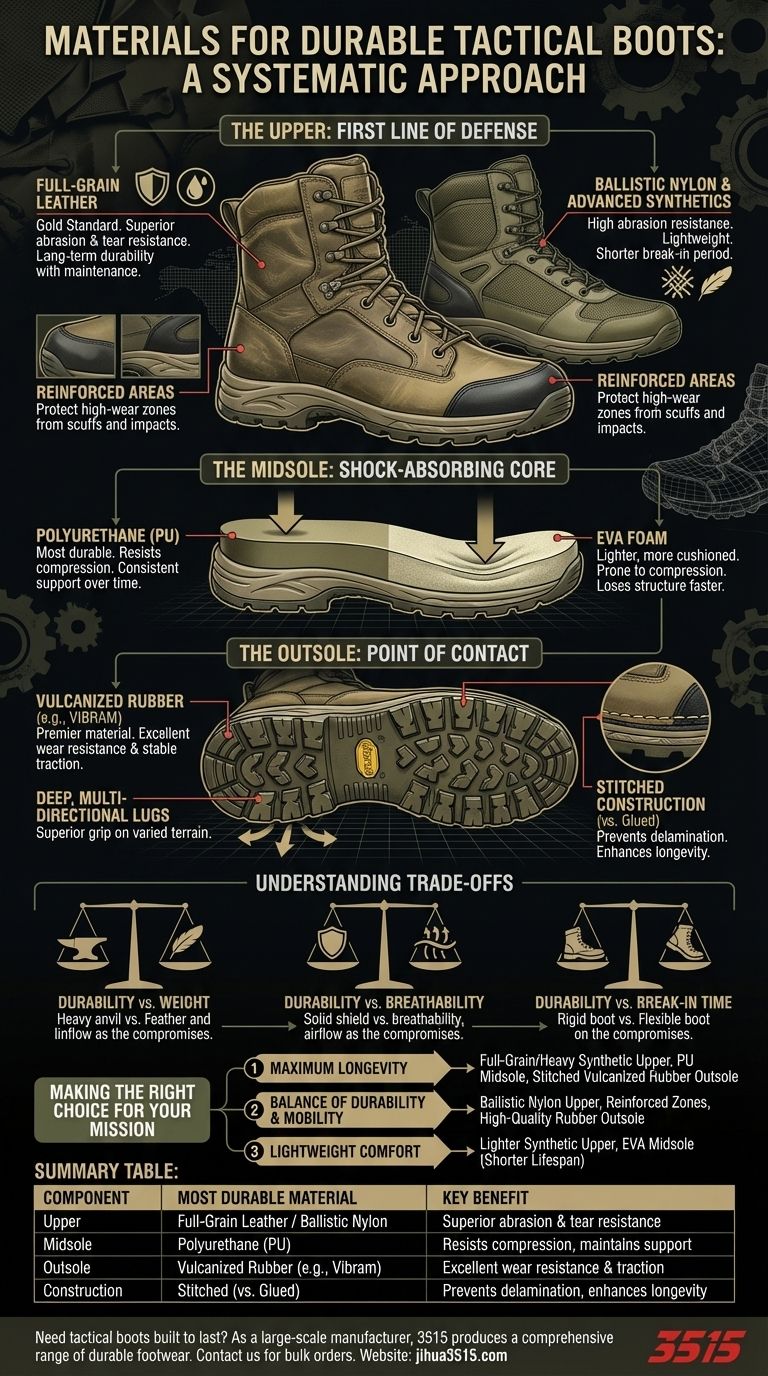

Deconstructing a Durable Boot: The Three Critical Zones

A tactical boot's lifespan is determined by the quality of its core components. To properly assess durability, you must look beyond the brand name and evaluate the specific materials used in each of these three functional zones.

The Upper: Your First Line of Defense

The upper is the part of the boot that covers your foot. It provides the primary protection against abrasion, cuts, and the elements.

Full-Grain Leather is the traditional gold standard for durability. It offers exceptional resistance to wear and tear and can be maintained for years with proper conditioning.

Ballistic Nylon and other advanced synthetics are excellent modern alternatives. These materials provide high levels of abrasion resistance at a significantly lower weight than leather and often require less of a break-in period.

Reinforced Areas, such as rubber toe caps and heel counters, are just as important as the primary material. They protect high-wear zones from scuffs and impacts, drastically extending the boot's life.

The Midsole: The Shock-Absorbing Core

The midsole is the crucial layer between your foot and the hard outsole. Its primary job is to absorb shock, and its durability determines how long the boot will provide support and prevent fatigue.

Polyurethane (PU) is the most durable midsole material. It is highly resistant to compression, meaning it won't "pack out" or flatten over time, providing consistent support for the life of the boot.

EVA (Ethylene-vinyl acetate) foam is a lighter and often more cushioned alternative. However, it is more prone to compression and will lose its supportive structure more quickly than PU, making it a less durable choice for heavy, long-term use.

The Outsole: The Point of Contact

The outsole is the rubber layer that meets the ground. It must resist constant abrasion while providing stable traction.

Vulcanized Rubber is the premier material for durable outsoles. Brands like Vibram are famous for creating compounds that offer an excellent balance of wear resistance and grip.

Deep, Multi-directional Lugs are a key feature of a durable outsole. This design provides superior traction and stability on varied terrain and indicates a focus on performance, not just appearance.

Stitched Construction is a hallmark of a high-quality boot. An outsole that is both glued and stitched to the upper is far less likely to delaminate or separate than one that is merely glued.

Understanding the Trade-offs

Choosing the most durable material in every category is not always the best strategy. True expertise lies in understanding the inherent compromises between absolute toughness and other performance characteristics.

Durability vs. Weight

The most durable materials are often the heaviest. A full-grain leather boot with a PU midsole and thick rubber outsole will offer maximum longevity but will also be heavier and less agile than a synthetic boot with an EVA midsole.

Durability vs. Breathability

Materials that offer the best protection from the elements, like thick leather or waterproof membranes, inherently reduce airflow. This can lead to heat and moisture buildup. Lighter synthetics with mesh panels improve breathability at the cost of durability and water resistance.

Durability vs. Break-In Time

The toughest, most supportive boots—particularly those made from high-quality leather—require a significant break-in period to conform to your foot. Lighter, more flexible boots are often comfortable out of the box but may not provide the same long-term structural support.

Making the Right Choice for Your Mission

Your final decision should be guided by your specific needs and the environment in which you'll be operating.

- If your primary focus is maximum longevity in harsh terrain: Prioritize a full-grain leather or heavy-duty synthetic upper, a PU midsole, and a stitched, vulcanized rubber outsole.

- If your primary focus is a balance of durability and athletic mobility: Look for a hybrid boot with a ballistic nylon upper, reinforced high-wear zones, and a high-quality rubber outsole.

- If your primary focus is lightweight comfort for less demanding conditions: A boot with a lighter synthetic upper and an EVA midsole may be suitable, but you must accept the shorter operational lifespan.

By evaluating a boot as a complete system of materials and construction, you can confidently select footwear that is truly built to last.

Summary Table:

| Component | Most Durable Material | Key Benefit |

|---|---|---|

| Upper | Full-Grain Leather / Ballistic Nylon | Superior abrasion & tear resistance |

| Midsole | Polyurethane (PU) | Resists compression, maintains support |

| Outsole | Vulcanized Rubber (e.g., Vibram) | Excellent wear resistance & traction |

| Construction | Stitched (vs. Glued) | Prevents delamination, enhances longevity |

Need tactical boots built to last? As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our expertise in selecting and combining the right materials—from full-grain leather to high-performance rubber outsoles—ensures your boots are designed for maximum longevity in the toughest conditions. Contact us today to discuss your specific requirements and benefit from our full-scale production capabilities for all types of shoes and boots.

Visual Guide

Related Products

- Durable Leather Tactical Boots Wholesale & Custom Manufacturing for Brands

- Durable Leather High-Ankle Tactical Boots for Wholesale & Custom Manufacturing

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

- Durable Leather Work Boots Wholesale Manufacturer & Custom Factory

People Also Ask

- Why should delivery drivers and postal service workers consider tactical footwear? Boost Safety & Endurance on Your Route

- How do tactical boots differ from regular footwear? A Guide to Purpose-Built Performance

- How do breathable tactical boots enhance comfort? Stay Cool, Dry, and Focused on Your Mission

- What safety features are available in tactical boots? Essential Protection for Demanding Roles

- What are the advantages and disadvantages of waterproof tactical boots? A Guide to the Key Trade-Offs

- How do advanced manufacturing techniques improve Tactical Boots? Explore High-Precision Performance and Durability

- What are the advantages of Men's Tactical Research Boots? Superior Mobility and All-Day Comfort

- What should be considered once the right winter tactical boot is selected? Ensure Perfect Integration for Mission Success