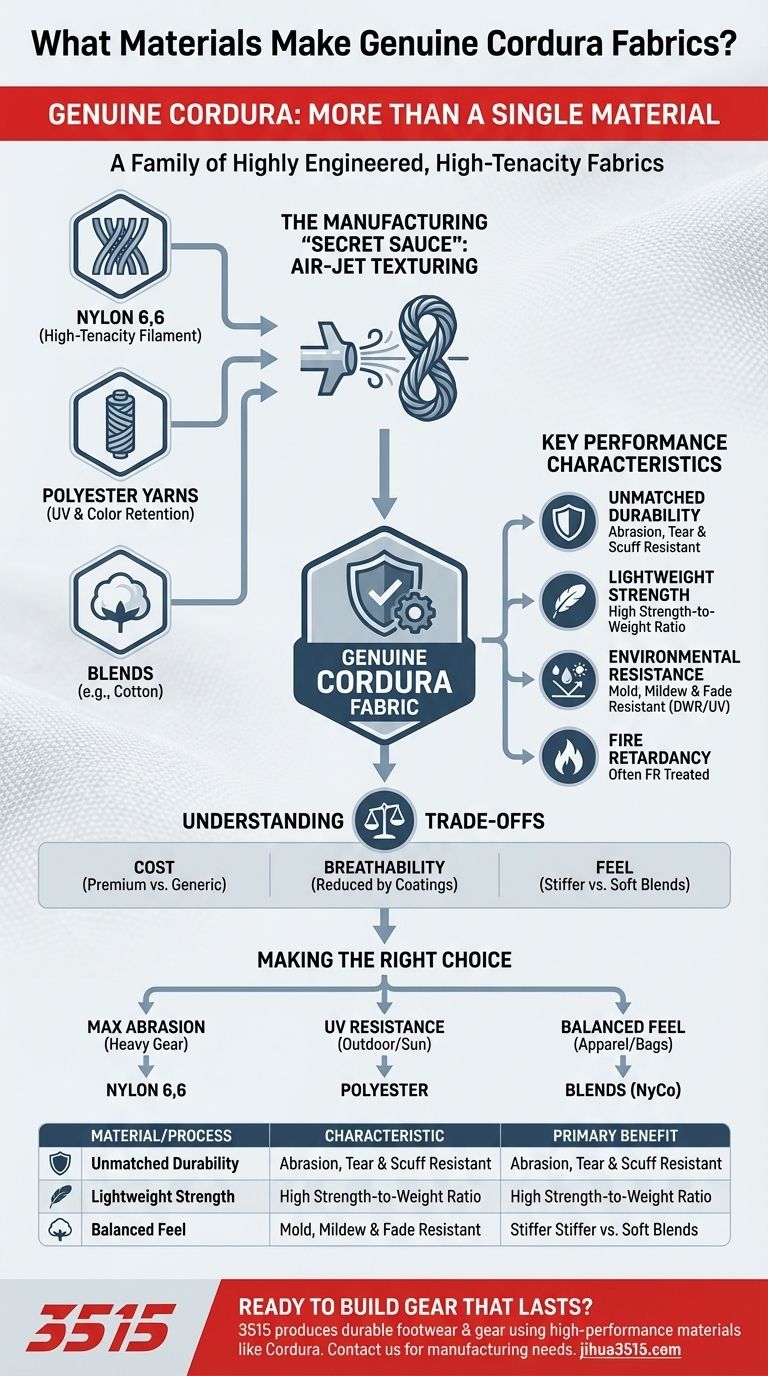

At its core, genuine Cordura fabric is primarily made from high-tenacity, air-jet textured nylon 6,6 filament yarns. While this specific type of nylon is the classic foundation for its legendary durability, the Cordura brand also encompasses fabrics made from polyester yarns or blends with other materials like cotton to achieve specific performance characteristics.

The key takeaway is that "Cordura" refers less to a single raw material and more to a family of highly engineered fabrics. The defining characteristic is the use of high-tenacity fibers (usually nylon 6,6) and a specialized manufacturing process, like air-jet texturing, designed to maximize durability above all else.

The Anatomy of a High-Performance Fabric

To understand why Cordura is a benchmark for rugged gear, we need to look beyond the base material and examine both the fibers and the process used to create the final fabric.

Nylon 6,6: The Classic Foundation

The most recognized Cordura fabrics start with nylon 6,6, a type of synthetic polymer known for its exceptional strength, toughness, and high melting point. These are not standard nylon fibers; they are "high-tenacity" filaments engineered for superior resilience.

The Role of Polyester

Cordura also produces fabrics based on polyester yarns. While slightly different in their chemical makeup, these versions are chosen for applications where properties like excellent UV resistance and color retention are critical, alongside robust durability.

The Manufacturing "Secret Sauce"

The raw material is only half the story. The process transforms these strong fibers into an exceptionally durable fabric.

The most critical step is air-jet texturing. This process takes smooth, flat filament yarns and uses a blast of high-pressure air to tangle and loop the fibers, creating a bulkier, matte-finish yarn that is significantly more abrasion-resistant than the original smooth filament.

After texturing, these yarns are woven into a fabric, often in a pattern that maximizes tear strength. The fabric is then dyed and finished with specialized coatings to enhance its performance, such as adding water repellency.

Key Performance Characteristics

The specific combination of materials and manufacturing gives Cordura its signature set of properties.

Unmatched Durability

Cordura's primary feature is its resistance to wear and tear. It is exceptionally resistant to abrasions, scuffs, and tears, with performance metrics showing it to be significantly more durable than standard nylon, polyester, and cotton duck fabrics.

Lightweight Strength

Despite its toughness, Cordura maintains a high strength-to-weight ratio. A typical fabric weighs around 11 ounces per square yard, delivering heavy-duty performance without excessive bulk.

Environmental Resistance

Engineered for harsh conditions, Cordura fabrics are inherently resistant to damage from mold and mildew. Finishes are often applied to provide excellent water repellency, and certain variants offer high resistance to fading from UV light.

Fire Retardancy

Many Cordura fabrics are treated to be flame-retardant, often complying with standards like the National Fire Protection Agency's 701 guidelines, making them suitable for protective apparel and gear.

Understanding the Trade-offs

No material is perfect for every application. Being an objective advisor means acknowledging the limitations and considerations.

Cost

Genuine Cordura is a premium, branded material. Its specialized fibers and manufacturing process mean it will carry a higher cost than generic, non-branded nylon or polyester fabrics.

Breathability vs. Water Resistance

While the base woven fabric is breathable, the topical coatings applied to make it highly water-repellent will inherently reduce that breathability. There is always a trade-off between keeping water out and letting moisture vapor escape.

Feel and Stiffness

Classic, heavy-duty Cordura fabrics can feel stiff and abrasive compared to softer materials. This is a direct trade-off for their extreme abrasion resistance. However, the brand does offer softer blends with cotton for apparel applications.

Making the Right Choice for Your Goal

Selecting the correct material depends entirely on your product's intended use and performance requirements.

- If your primary focus is maximum abrasion resistance for heavy gear (backpacks, luggage, military equipment): Choose a classic, high-tenacity nylon 6,6 Cordura fabric.

- If your primary focus is UV resistance for outdoor equipment that sees constant sun exposure: A polyester-based Cordura may offer superior color stability and longevity.

- If your primary focus is balancing durability with a softer feel for apparel or everyday bags: Consider Cordura fabrics blended with cotton (often branded as Cordura NyCo).

Ultimately, choosing a Cordura fabric is an investment in long-term performance and proven durability.

Summary Table:

| Material / Process | Key Characteristic | Primary Benefit |

|---|---|---|

| Nylon 6,6 | High-tenacity filament yarns | Maximum abrasion & tear resistance |

| Polyester | Excellent UV resistance | Superior color retention & sun resistance |

| Air-Jet Texturing | Manufacturing process | Creates bulkier, more abrasion-resistant yarns |

| Blends (e.g., with Cotton) | Combines materials | Balances durability with a softer feel (Cordura NyCo) |

Ready to build gear that lasts? As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear and gear for distributors, brand owners, and bulk clients. Our expertise in high-performance materials like Cordura ensures your products meet the highest standards of durability and quality. Contact our team today to discuss your manufacturing needs and bring your vision to life.

Visual Guide

Related Products

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Wholesale Classic Leather Lace-Up Ankle Boots for Brand Manufacturing

- Wholesale Durable Camo Canvas Shoes with High-Traction Rubber Soles

People Also Ask

- What is the purpose of the shoe care guide? Protect Your Investment and Elevate Your Style

- What do the Stability Index and Sway Index represent? Data-Driven Footwear Balance Performance Guide

- How have Advanced Fabrics impacted various industries? Discover the Engineered Textiles Revolution

- Why is the use of blue-colored visual consumables mandatory? Enhancing Safety in Food and Precision Manufacturing

- What role does Bluetooth connectivity and mobile applications play in smart vibratory insoles? Precision Digital Control

- What is the function of scientific safety stock for footwear? Master Inventory Stability for Volatile Shoe Categories

- What are the advantages of wireless Bluetooth transmission for sensorized insoles? Safety & Mobility in Rehabilitation

- What is the primary role of shoes in physical activities? Protection, Support & Performance