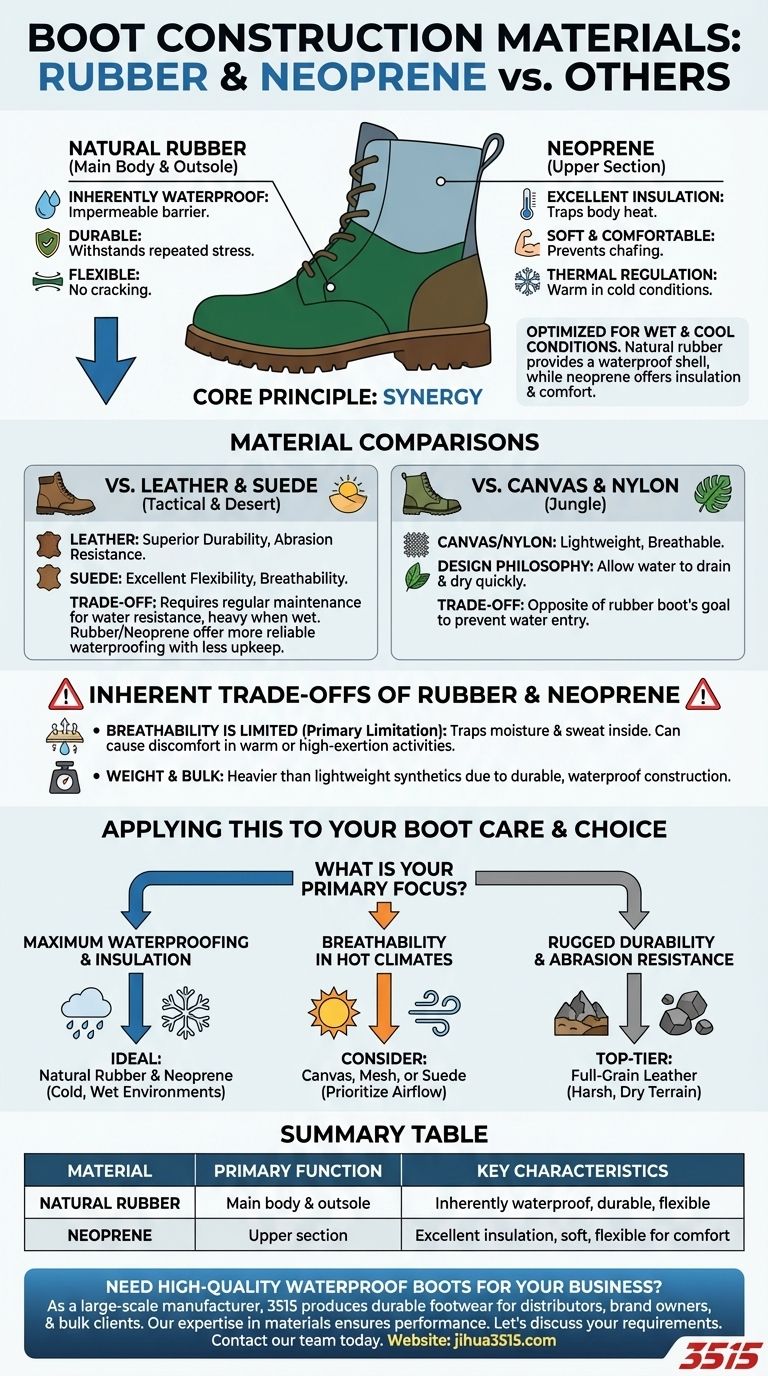

The boots in question are constructed from two primary materials: high-grade natural rubber for the main body and neoprene for the upper. This specific combination is chosen to deliver a unique balance of durability, flexibility, and protection from the elements.

The core principle behind this design is synergy. Natural rubber provides a completely waterproof and durable shell, while the flexible neoprene upper offers insulation and comfort, creating a boot optimized for wet and cool conditions.

Understanding the Core Materials

To grasp why these boots perform the way they do, it's essential to understand the distinct properties of each component. These materials are not chosen by accident; their characteristics directly serve the boot's intended function.

The Role of Natural Rubber

Natural rubber forms the primary structure of the boot, including the entire lower section and the outsole. Its key function is to provide an impermeable barrier against water.

Unlike leather or textiles, which require treatments to become water-resistant, rubber is inherently waterproof. This material also offers excellent flexibility and durability, allowing it to withstand repeated stress without cracking.

The Function of the Neoprene Upper

Neoprene is a type of synthetic rubber best known for its use in wetsuits. Its inclusion in the boot's upper section is a deliberate choice for comfort and thermal regulation.

Neoprene is an excellent insulator, trapping body heat to keep you warm in cold water or air. It is also exceptionally flexible and soft, which prevents the chafing and stiffness that can occur with a full rubber boot.

How These Materials Compare to Other Boot Types

The rubber and neoprene combination stands in contrast to materials used in other specialized footwear. Understanding these differences clarifies when your boots are the right tool for the job.

vs. Leather and Suede (Tactical & Desert Boots)

Boots made from full-grain leather, common in police and tactical models, offer superior durability and abrasion resistance. Suede, used in desert boots, provides excellent flexibility and breathability.

However, both leather and suede require regular maintenance to maintain water resistance and can become heavy when saturated. Rubber and neoprene offer more reliable waterproofing with less upkeep.

vs. Canvas and Nylon (Jungle Boots)

Jungle boots originally used canvas and leather, while modern versions often use ballistic nylon. These materials are chosen for their light weight and breathability.

The design philosophy for these boots is that feet will get wet in a jungle, so the boot should be able to drain and dry as quickly as possible. This is the opposite of the rubber boot's goal, which is to prevent water from ever getting in.

The Inherent Trade-offs of Rubber and Neoprene

No material choice is without its compromises. Being aware of the limitations of rubber and neoprene is crucial for getting the best performance from your boots.

Breathability is the Primary Limitation

The greatest trade-off is breathability. Because rubber and neoprene create a waterproof seal to keep water out, they also trap moisture and sweat inside.

In warm conditions or during high-exertion activities, this can lead to discomfort. Boots designed for hot weather often incorporate mesh panels specifically to allow for airflow, a feature this construction lacks.

Weight and Bulk

Compared to boots made of lightweight synthetics like nylon, a natural rubber boot can feel heavier and bulkier. This is a direct consequence of its durable and waterproof construction.

Applying This to Your Boot Care

Understanding these materials directly informs how you should care for your boots and what to expect from them.

- If your primary focus is maximum waterproofing and insulation: This natural rubber and neoprene construction is an ideal choice, perfectly suited for cold, wet environments.

- If your primary focus is breathability in hot climates: You should consider boots made from canvas, mesh, or suede, which prioritize airflow over insulation.

- If your primary focus is rugged durability and abrasion resistance: A full-grain leather boot, common in tactical or police footwear, remains the top-tier choice for harsh, dry terrain.

By recognizing the purpose behind your boots' materials, you can better align them with their intended use and provide the proper care they require.

Summary Table:

| Material | Primary Function | Key Characteristics |

|---|---|---|

| Natural Rubber | Main body & outsole | Inherently waterproof, durable, flexible |

| Neoprene | Upper section | Excellent insulation, soft, flexible for comfort |

Need High-Quality Waterproof Boots for Your Business?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our expertise in materials like natural rubber and neoprene ensures your customers get the performance they need.

Let's discuss your specific requirements and how we can support your supply chain.

Contact our team today for a quote

Visual Guide

Related Products

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- What is the recommended method for removing rubber boots after use? Preserve Your Boots with the Right Tool

- What happens after the PVC rain boots are injection molded? From Raw Mold to Ready-to-Wear

- Why is thorough rinsing important after washing waterproof shoes? Preserve Performance & Longevity

- Are Wellington boots true to size? The Definitive Guide to Finding Your Perfect Fit

- Should you wear neoprene socks with Wellington boots? Maximize Warmth and Comfort

- What factors should be considered when choosing the best Wellington boots? Find Your Perfect Fit for Any Task

- What is a simple tip to make wellies last longer? Rinse & Dry for Maximum Lifespan

- Why should you never store damp rubber boots? Protect Your Investment from Mold & Decay