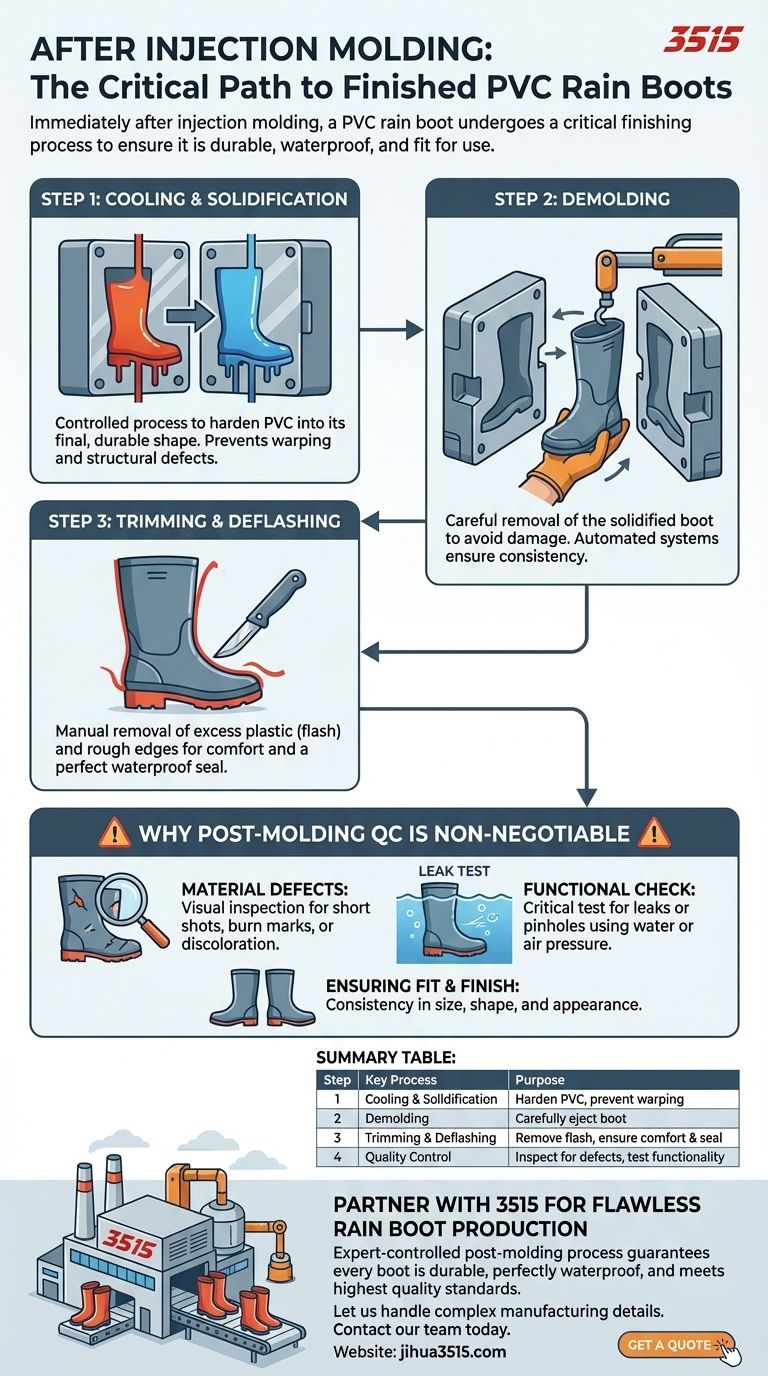

Immediately after injection molding, a PVC rain boot undergoes a critical finishing process. The newly formed boot must first cool and solidify within the mold before it can be removed, after which workers meticulously trim any excess material and perform rigorous quality control checks to ensure it is fit for use.

The injection molding machine creates the boot's shape, but the essential post-molding steps—cooling, trimming, and inspection—are what transform a raw plastic form into a durable, waterproof, and finished product.

From Raw Form to Finished Product

Injection molding is a high-speed process that forms the basic structure of the boot. However, this raw molding is not the final product. Several careful steps are required to ensure each boot meets functional and aesthetic standards.

Step 1: Cooling and Solidification

Once the molten PVC is injected into the mold, a cooling phase begins. This is a controlled process where the material hardens into its final, durable shape.

Proper cooling is essential to prevent warping or structural defects. The time required depends on the thickness of the PVC and the complexity of the boot design.

Step 2: Demolding

After the boot has solidified completely, the two halves of the mold are opened, and the boot is ejected or removed by a worker.

This step must be done carefully to avoid damaging the still-warm boot. Automated ejector pins or robotic arms are often used in modern manufacturing to ensure consistency and prevent handling errors.

Step 3: Trimming and Deflashing

The injection process often leaves behind a thin line of excess plastic, known as "flash," where the mold halves meet.

Workers manually trim this flash and any other rough edges from the boot. This step is crucial for both comfort and ensuring a perfect waterproof seal, especially around the top opening of the boot.

Why Post-Molding Quality Control is Non-Negotiable

Skipping or rushing the finishing steps can lead to critical product failures. The integrity of a rain boot depends entirely on its ability to be a flawless, waterproof barrier.

The Risk of Material Defects

A visual inspection is the first line of defense. Quality control technicians look for common molding defects like short shots (incomplete parts), burn marks, or discoloration, which can indicate problems with the PVC or the machine.

The Importance of a Functional Check

The most critical check is for leaks or pinholes. Boots may be filled with water or air and pressurized to ensure they are completely waterproof. A single, tiny flaw renders the entire boot useless for its primary purpose.

Ensuring Proper Fit and Finish

Finally, the boots are checked for consistency in size, shape, and overall appearance. A poorly trimmed boot is not only uncomfortable but also reflects low production standards, directly impacting brand reputation.

Making the Right Choice for Your Production Goal

The focus of your post-molding process depends on what you value most in the final product.

- If your primary focus is maximum durability and performance: Prioritize rigorous leak testing and material integrity checks for every single boot.

- If your primary focus is a flawless aesthetic finish: Emphasize a meticulous, multi-stage trimming and polishing process to remove all traces of flash and molding artifacts.

Ultimately, these finishing steps are what guarantee the boot will perform its essential function reliably.

Summary Table:

| Step | Key Process | Purpose |

|---|---|---|

| 1 | Cooling & Solidification | Harden PVC into final shape, prevent warping |

| 2 | Demolding | Carefully eject the solidified boot from the mold |

| 3 | Trimming & Deflashing | Remove excess plastic (flash) for comfort and waterproof seal |

| 4 | Quality Control | Inspect for defects and test for leaks to ensure functionality |

Partner with 3515 for Flawless Rain Boot Production

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our expert-controlled post-molding process—including precise cooling, meticulous trimming, and rigorous leak testing—guarantees that every PVC rain boot is durable, perfectly waterproof, and meets the highest quality standards.

Let us handle the complex manufacturing details so you can deliver reliable products to your market. Contact our team today to discuss your production needs and get a quote.

Visual Guide

Related Products

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

People Also Ask

- What are the recommended sustainable materials for Wellington boots? Choose Natural Rubber for Eco-Friendly Performance

- What types of footwear are related to women's wellington boots? A Guide to Functional Footwear Choices

- How do sustainable wellies contribute to circular fashion? The 3-Pillar Strategy for Eco-Friendly Footwear

- Which non-sustainable materials should be avoided in Wellington boots? Protect the Planet with Eco-Conscious Footwear

- What are the benefits of wellington boots with a removable insole? Unlock All-Day Comfort & Support

- What materials are modern Wellington boots made from? Natural Rubber vs. PVC Explained

- What are the key differences between neoprene-lined and regular Wellington boots? Choose the Right Boot for Any Climate

- What standards do PVC boots comply with? Essential Safety Certifications Explained