At their core, snake boots are constructed from materials specifically chosen for high puncture and abrasion resistance. The most common materials for the main body of the boot are thick full-grain leather, durable synthetics like Cordura nylon, or molded compounds such as PVC and rubber.

The effectiveness of a snake boot isn't about a single "magic" material, but about using a material or a combination of layers that are too dense and tough for a snake's fangs to penetrate. Your choice of material is a direct trade-off between protection, weight, flexibility, and waterproofing.

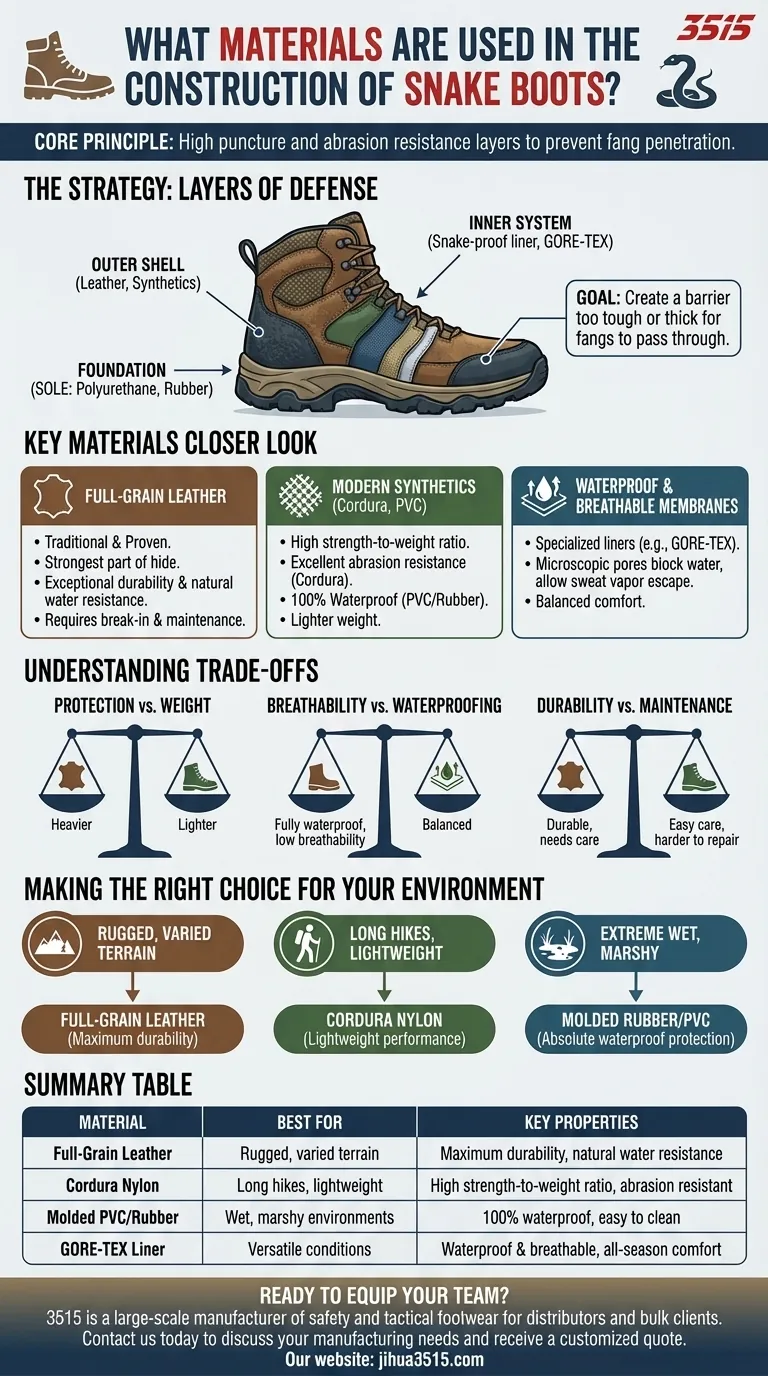

The Strategy Behind Snake-Proof Construction

Snake boots are engineered with one primary goal: to prevent fangs from reaching your skin. This is achieved by creating a barrier that is either too tough to pierce or too thick to pass through.

The Outer Shell: The First Line of Defense

The exterior material of the boot is what faces the initial impact. It must be rugged enough to withstand not only a potential strike but also the harsh terrain where you'll be walking.

The two main categories for this outer shell are leather and synthetics.

The Inner System: Protection and Comfort

Many modern snake boots employ a layered system. Beneath the outer shell, they may have a dedicated snake-proof fabric liner.

Interior linings are also critical for comfort, with materials like polyester used for moisture-wicking, and membranes like GORE-TEX added for waterproofing and breathability.

The Foundation: The Sole

The sole of the boot provides traction and a final layer of protection from below. Materials like polyurethane and rubber are standard choices due to their durability and grip.

A Closer Look at Key Materials

Each material offers a distinct set of properties that affect the boot's performance, comfort, and ideal use case.

Full-Grain Leather

This is the traditional, time-tested material for snake boots. It uses the strongest part of the animal hide, offering exceptional durability and natural water resistance.

Leather boots are known for their long-term toughness but often require a break-in period and periodic maintenance to stay in prime condition.

Modern Synthetics (Nylon, Cordura, PVC)

Materials like Cordura nylon are woven fabrics renowned for their incredible strength-to-weight ratio. They provide excellent abrasion resistance in a much lighter package than leather.

Other synthetics, like polyvinyl chloride (PVC) or rubber, are used to create fully molded, 100% waterproof boots, ideal for swampy or extremely wet environments.

Waterproof & Breathable Membranes

Specialized liners like GORE-TEX or Sympatex are often laminated inside the boot, between the outer shell and your foot.

These membranes have microscopic pores that are large enough to let sweat vapor escape but too small for water droplets to enter, providing an excellent balance of waterproofing and comfort in varied conditions.

Understanding the Trade-offs

Choosing the right snake boot means understanding the compromises inherent in each material. No single boot is perfect for every person or every situation.

Protection vs. Weight

Full-grain leather offers proven, rugged protection but is typically the heaviest option. Synthetics like nylon provide comparable bite resistance while significantly reducing the boot's overall weight, which reduces fatigue on long treks.

Breathability vs. Waterproofing

Molded rubber or PVC boots are completely waterproof but offer zero breathability, which can lead to discomfort in hot weather. Boots with GORE-TEX liners offer a compromise, keeping water out while allowing sweat to escape. Less-protected materials like suede leather or mesh panels offer the highest breathability for hot, dry climates.

Durability vs. Maintenance

Leather is exceptionally durable but requires cleaning and conditioning to prevent it from drying out and cracking. Synthetics are generally easier to care for, often requiring little more than being hosed off, but can be more difficult to repair if punctured or torn.

Making the Right Choice for Your Environment

Your decision should be based on where you'll be and what you'll be doing.

- If your primary focus is maximum durability for rugged, varied terrain: A high-quality full-grain leather boot is a time-tested and reliable choice.

- If your primary focus is lightweight performance for long hikes: Look for boots made with Cordura nylon uppers, often paired with a waterproof membrane.

- If your primary focus is hunting or working in extremely wet, marshy areas: A molded rubber or PVC boot will provide the absolute best waterproof protection.

Ultimately, understanding these materials empowers you to choose the right tool to ensure your safety and comfort in the wild.

Summary Table:

| Material | Best For | Key Properties |

|---|---|---|

| Full-Grain Leather | Rugged, varied terrain | Maximum durability, natural water resistance |

| Cordura Nylon | Long hikes, lightweight needs | High strength-to-weight ratio, abrasion resistant |

| Molded PVC/Rubber | Wet, marshy environments | 100% waterproof, easy to clean |

| GORE-TEX Liner | Versatile, changing conditions | Waterproof & breathable, all-season comfort |

Ready to Equip Your Team with Durable, Protective Footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety and tactical footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of durable boots, including specialized designs for extreme environments.

We can help you provide reliable footwear that meets the highest standards of protection and comfort.

Contact us today to discuss your manufacturing needs and receive a customized quote.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Durable Rubber Sole Outdoor Shoes Wholesale & Custom Manufacturing

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- Why is proper boot care important for winter footwear? Protect Your Health, Safety & Investment

- How do waterproof materials benefit winter boots? Keep Feet Warm and Dry in Harsh Conditions

- What are the characteristics of walking boots? Essential Features for Rugged Terrain & Heavy Loads

- What topics are covered in a western boots guide? Your Essential Handbook to Styles, Fit & Care

- What are the advantages of zip-up boots for streetbike riders? Speed, Convenience & Weatherproofing

- What are some tips for maintaining the shine on tall boots? A Guide to a Lasting, High-Gloss Finish

- Why is it recommended to shorten your stride while wearing a walking boot? To Protect Your Hips, Knees, and Back

- What types of injuries typically require a walking boot? A Guide to Controlled Healing