At their core, combat boots are constructed from a strategic combination of materials. The most common are rugged full-grain leather for durability and modern synthetic fabrics like nylon for reduced weight and breathability. These primary materials are supported by high-traction rubber outsoles and internal reinforcements to create a piece of high-performance footwear.

The construction of a combat boot is not about a single material, but an engineered system. Each element is chosen for a specific function—durability, support, traction, or protection—to ensure performance in the most demanding environments.

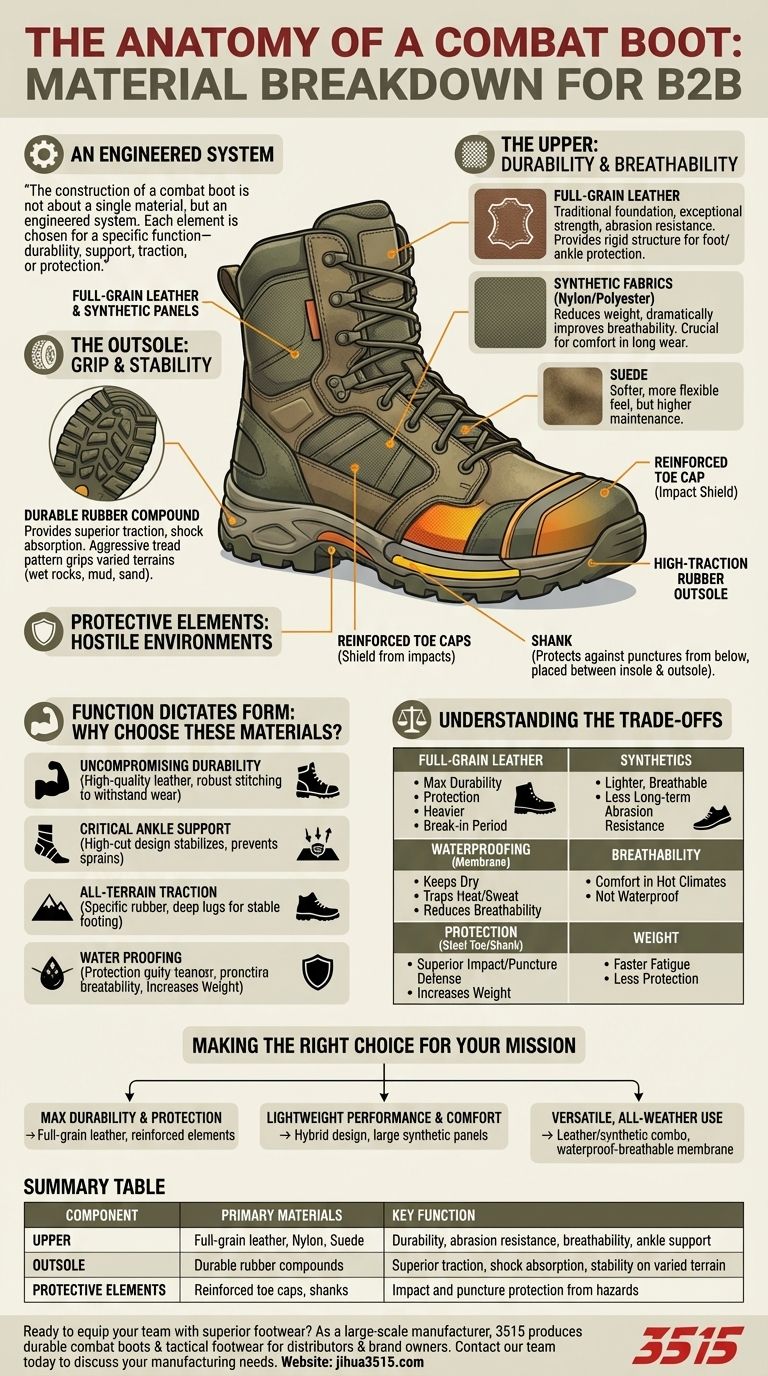

The Anatomy of a Combat Boot: A Material Breakdown

A combat boot is a sum of its parts, with each component's material carefully selected to fulfill a critical role. Understanding this anatomy reveals why they are so effective.

The Upper: Balancing Durability and Breathability

The upper is the main body of the boot that covers the foot. It's where the balance between toughness and comfort is most critical.

Full-grain leather is the traditional foundation, prized for its exceptional strength and resistance to abrasion. It provides a rigid structure that protects the foot and ankle.

Modern boots frequently integrate synthetic materials like nylon or rugged polyester panels. These fabrics significantly reduce the boot's overall weight and dramatically improve breathability, which is crucial for comfort during long periods of wear.

In some designs, suede is used. While still a type of leather, it offers a softer, more flexible feel but typically requires more maintenance.

The Outsole: The Foundation of Grip and Stability

The outsole is the point of contact with the ground, making its material composition vital for safety and performance.

Virtually all combat boot outsoles are made from a durable rubber compound. This material is chosen for its ability to provide superior traction and absorb shock from impacts.

This rubber is molded into an aggressive tread pattern designed to grip a wide variety of terrains, from wet rocks and mud to loose sand and gravel.

Protective Elements: Reinforcing for Hostile Environments

Combat boots are designed to protect the wearer from environmental hazards, a function achieved through reinforced internal and external structures.

Many models include reinforced toe caps to shield the foot from impacts. Similarly, a rigid piece of material known as a shank is often placed between the insole and outsole to protect against punctures from below.

Function Dictates Form: Why These Materials Are Chosen

The material selection in a combat boot is never arbitrary; it is a direct response to the functional demands of military and tactical use.

Uncompromising Durability

The primary need is for footwear that will not fail under rigorous conditions. High-quality leather and robust stitching are used to ensure the boot can withstand extreme wear and tear.

Critical Ankle Support

The high-cut design, typically made from less flexible materials like leather, is essential for stabilizing the ankle. This feature is critical for preventing sprains and other injuries when moving over uneven ground with a heavy load.

All-Terrain Traction

The specific rubber compounds and deep lug patterns of the outsole are engineered to provide a stable footing in any environment. This ensures the wearer can move confidently and safely across unpredictable surfaces.

Understanding the Trade-offs

Choosing a combat boot involves balancing competing priorities. The ideal material for one characteristic is often a compromise for another.

Full-Grain Leather vs. Synthetics

A boot made entirely of full-grain leather offers maximum durability and protection but is heavier and requires a significant "break-in" period. A boot with large synthetic panels is much lighter and more breathable from the start but may offer less long-term abrasion resistance.

Waterproofing vs. Breathability

Many boots are treated with waterproofing membranes. While this is excellent for keeping feet dry in wet conditions, it can trap sweat and heat, reducing breathability and causing discomfort in hot, dry climates.

Protection vs. Weight

Features like steel toe caps or thick shanks offer superior protection against impact and puncture. However, these additions increase the boot's weight, which can lead to faster fatigue over long distances.

Making the Right Choice for Your Mission

The ideal combat boot depends entirely on its intended use and environment.

- If your primary focus is maximum durability and protection: Choose a boot constructed predominantly from full-grain leather with reinforced toe and shank elements.

- If your primary focus is lightweight performance and comfort: Look for a hybrid design that incorporates large nylon or synthetic panels to reduce weight and improve breathability.

- If your primary focus is versatile, all-weather use: Seek out a boot with a combination of leather and synthetic materials that includes a reputable waterproof-breathable membrane.

Ultimately, the materials in a combat boot are purpose-driven, designed to provide a reliable platform that allows you to focus on the task at hand.

Summary Table:

| Component | Primary Materials | Key Function |

|---|---|---|

| Upper | Full-grain leather, Nylon, Suede | Durability, abrasion resistance, breathability, and ankle support |

| Outsole | Durable rubber compounds | Superior traction, shock absorption, and stability on varied terrain |

| Protective Elements | Reinforced toe caps, shanks | Impact and puncture protection from hazards |

Ready to equip your team with superior footwear? As a large-scale manufacturer, 3515 produces a comprehensive range of durable combat boots and tactical footwear for distributors, brand owners, and bulk clients. Our expertise in material selection and construction ensures high-performance boots tailored to your specific mission requirements. Contact our team today to discuss your manufacturing needs and discover how we can bring reliability and quality to your product line.

Visual Guide

Related Products

- Durable Military Combat Boots with Water Drainage for Wholesale & OEM

- Durable Leather Tactical Boots Wholesale & Custom Manufacturing for Brands

- Wholesale Tactical Boots High-Traction & Reflective for Bulk & Brand Orders

- Durable Leather High-Ankle Tactical Boots for Wholesale & Custom Manufacturing

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

People Also Ask

- What materials are used in military camouflage boots? A Guide to Durable & Breathable Footwear

- What are the key considerations when choosing military boots? Prioritize Compliance, Environment & Fit

- What are the benefits of maintaining military boots? Ensure Mission Readiness and Maximize Lifespan

- Can regular soap be used to clean military boots? Choose the Right Soap to Protect Your Investment

- What are the five key reasons why combat boots are important? Essential Gear for Safety and Performance

- What are the five key areas to consider when choosing military boots? Find the Right Boot for Your Mission

- What features does the responsive insole in modern jungle boots provide? Dynamic Comfort for Long Treks

- Do desert boots stretch over time? Get the Perfect Fit from Day One