For truly durable police boots, the best materials are a combination of high-quality, full-grain leather or rugged synthetic fabrics like Cordura for the upper, paired with a high-traction rubber or Vibram outsole. Critically, the boot's construction method is as important as its materials; soles that are both stitched and glued to the upper offer vastly superior longevity compared to those that are merely glued.

The durability of a police boot is not determined by a single material, but by a system of components working together. The key is to evaluate the quality of the upper material, the resilience of the outsole, and—most importantly—the strength of the construction that bonds them.

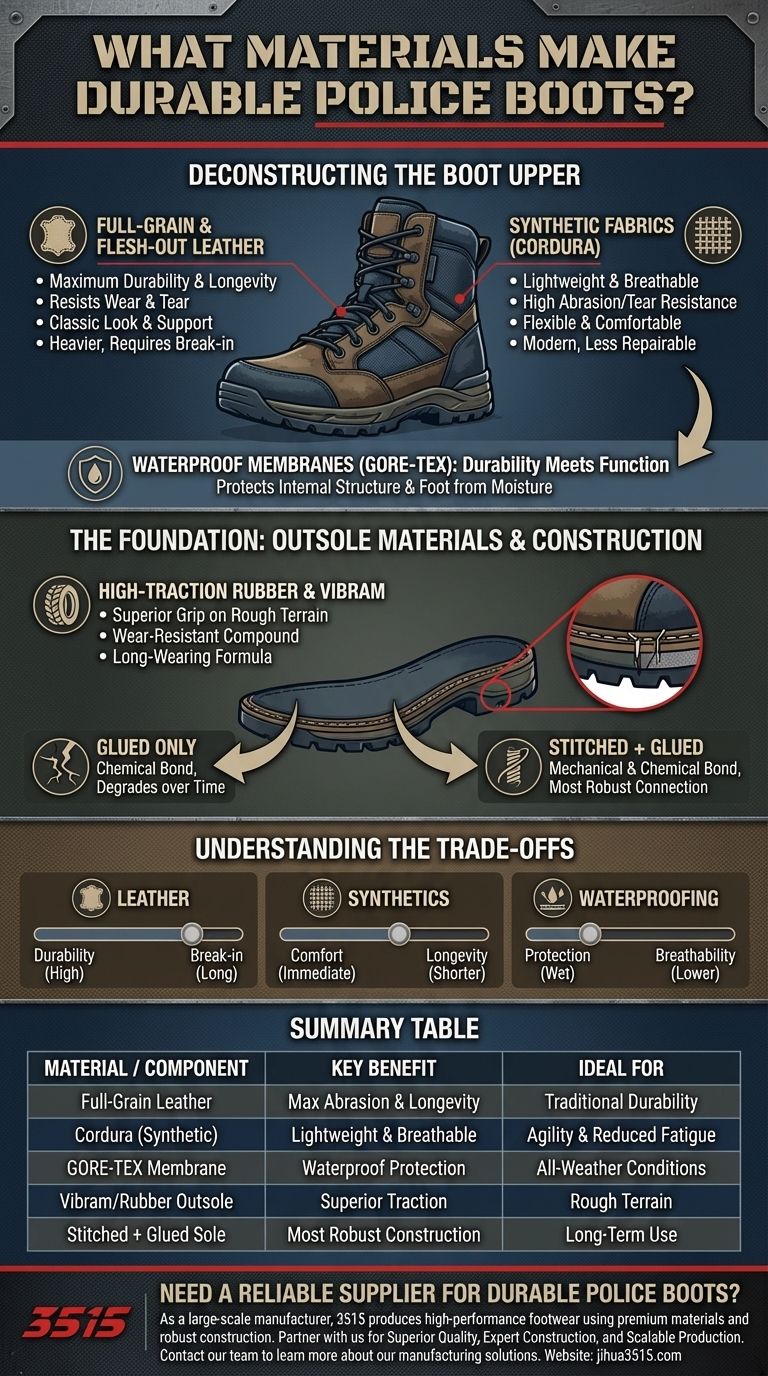

Deconstructing the Boot Upper: Leather vs. Synthetics

The "upper" is the entire part of the boot that covers the foot. The choice of material here dictates the boot's resistance to abrasion, its flexibility, and its environmental protection.

Full-Grain and Flesh-Out Leather: The Gold Standard

Full-grain or flesh-out leather is the top choice for maximum durability and longevity. This material is tough, resists wear and tear from daily use, and can be maintained for years with proper care. It provides a classic look and excellent support.

Synthetic Fabrics (Cordura): The Modern Alternative

Modern synthetic fabrics, most notably Cordura (a high-performance nylon blend), offer an excellent alternative to leather. Cordura is exceptionally resistant to abrasions and tears while being significantly lighter and more breathable than traditional leather. Many high-quality boots use a hybrid design, combining leather in high-wear areas with Cordura panels for flexibility and reduced weight.

Waterproof Membranes (GORE-TEX): Durability Meets Function

A boot's ability to keep your feet dry is a critical component of its functional durability. A waterproof and breathable membrane like GORE-TEX is laminated to the inside of the upper. This protects the boot's internal structure and your foot from moisture, preventing material breakdown and ensuring comfort in harsh conditions.

The Foundation: Outsole Materials and Construction

A boot is only as strong as its foundation. The outsole and the method used to attach it are where many boots fail prematurely.

High-Traction Rubber and Vibram: The Non-Negotiable Outsole

The outsole is the part of the boot that contacts the ground. For police work, it must be made from a durable, slip-resistant compound. High-quality rubber is the standard, with Vibram being a well-regarded brand known for its exceptional grip and long-wearing formulas. These materials can handle rough terrain without breaking down quickly.

The Critical Bond: Stitched vs. Glued Soles

This is one of the most overlooked aspects of boot durability. A sole that is only glued on relies on a chemical bond that can degrade over time, especially with exposure to moisture and flexing. A boot with stitched seams (often called a Goodyear welt or similar construction) adds a physical, mechanical bond. Boots that are both stitched and glued offer the most robust and long-lasting connection possible.

Reinforced Areas for Added Strength

True durability comes from reinforcing key stress points. Look for features like reinforced toe caps (sometimes steel or a composite material) and extra stitching in areas around the heel and eyelets. These small details prevent catastrophic failures during demanding use.

Understanding the Trade-offs

No single material is perfect for every situation. Choosing the right boot requires understanding the inherent compromises.

Leather: The Durability vs. Break-in Dilemma

Full-grain leather is unmatched for long-term wear but often requires a significant break-in period to become comfortable. It is also typically heavier than synthetic options and requires regular cleaning and conditioning to maintain its properties.

Synthetics: The Weight vs. Long-Term Wear Reality

Synthetic and hybrid boots are comfortable right out of the box and are much lighter, reducing fatigue. However, while highly durable against abrasion, they typically cannot be repaired or resoled as easily as a stitched leather boot, potentially leading to a shorter overall lifespan.

Waterproofing: The Breathability Compromise

A waterproof membrane is essential for wet climates, but it will always be less breathable than a non-waterproof boot. In consistently hot and dry environments, this can lead to excessive sweat and discomfort.

Making the Right Choice for Your Role

Your specific duties and environment should dictate your choice of materials.

- If your primary focus is maximum lifespan and traditional durability: Choose a boot with a full-grain leather upper and a sole that is both stitched and glued.

- If your primary focus is lightweight agility and out-of-the-box comfort: Look for a hybrid boot combining leather with Cordura panels and a high-quality Vibram or rubber outsole.

- If your primary focus is all-weather, all-condition reliability: Prioritize a boot with a certified waterproof membrane like GORE-TEX, regardless of the primary upper material.

Ultimately, investing in a boot made from superior materials and robust construction is investing in a critical piece of equipment that will perform when you need it most.

Summary Table:

| Material / Component | Key Benefit | Ideal For |

|---|---|---|

| Full-Grain Leather | Maximum abrasion resistance & longevity | Traditional durability & support |

| Cordura (Synthetic) | Lightweight, breathable, & abrasion-resistant | Agility & reduced fatigue |

| GORE-TEX Membrane | Waterproof & breathable protection | All-weather, wet conditions |

| Vibram/Rubber Outsole | Superior traction & wear resistance | Rough terrain & slip resistance |

| Stitched + Glued Sole | Most robust construction for long-term use | Preventing sole separation |

Need a reliable supplier for durable police boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-performance footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of durable boots, built with the premium materials and robust construction methods detailed above.

Partner with us to get:

- Superior Quality: Boots crafted from top-tier materials like full-grain leather, Cordura, and Vibram soles.

- Expert Construction: Utilizing techniques like stitched and glued soles for maximum durability.

- Scalable Production: Reliable supply to meet the demands of distributors and major brands.

Let's discuss your specific needs. Contact our team today to request a quote or learn more about our manufacturing solutions.

Visual Guide

Related Products

- Wholesale Durable Mid-Cut Tactical Boots for Custom & Private Label Brands

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Durable Leather High-Ankle Tactical Boots for Wholesale & Custom Manufacturing

- Wholesale Lightweight Tactical Boots with Dial Closure OEM & Bulk Orders

People Also Ask

- What features should be considered when choosing duty boots? A Guide to Optimal Performance & Safety

- Why are police boots considered important tools for officers? The Foundation of Officer Safety and Performance

- What are the main types of police footwear? A Guide to Durable & Specialized Footwear

- How do police boots perform in different weather conditions? Engineered for All-Weather Duty

- Why might an officer prefer police shoes over boots? For Superior Comfort & Agility on Duty

- What should be considered when choosing police tactical boots? The Ultimate Guide for Safety & Performance

- Why is it important to select a reliable provider for police tactical boots? Ensure Officer Safety & Performance

- What additional uses do police boots have beyond law enforcement? Discover Their Versatility for Demanding Tasks